|

Machine Tending

{{unreferenced, date=August 2016 Machine tending refers to the automated operation of industrial machine tools in a manufacturing plant, primarily using robot automation systems. While loading and unloading is the primary function of machine tending systems, often the robot performs other valuable functions within the automation system such as part inspection, blow off, wash, deburring, sorting, packaging and gauging. Benefits of machine tending systems include: # increased productivity # decreased manufacturing labor # decreased overall costs # improved quality # enhanced safety # operational flexibility # inventory optimization Because of the sophistication, functionality and costs associated with machine tending systems, most manufacturers require a capital approval process prior to investing in these systems where executive management must approve the purchase. Typically, an ROI (return on investment Return on investment (ROI) or return on costs (ROC) is a ratio between ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine

A machine is a physical system using power to apply forces and control movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to natural biological macromolecules, such as molecular machines. Machines can be driven by animals and people, by natural forces such as wind and water, and by chemical, thermal, or electrical power, and include a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement. They can also include computers and sensors that monitor performance and plan movement, often called mechanical systems. Renaissance natural philosophers identified six simple machines which were the elementary devices that put a load into motion, and calculated the ratio of output force to input force, known today as mechanical advantage. Modern machines are complex systems that consist of structural elements, mechanisms and control com ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Robotic Automation Software

Robotic process automation (RPA) is a form of business process automation technology based on metaphorical software robots (bots) or on artificial intelligence (AI)/digital workers. It is sometimes referred to as ''software robotics'' (not to be confused with robot software). In traditional workflow automation tools, a software developer produces a list of actions to automate a task and interface to the back end system using internal application programming interfaces (APIs) or dedicated scripting language. In contrast, RPA systems develop the action list by watching the user perform that task in the application's graphical user interface (GUI), and then perform the automation by repeating those tasks directly in the GUI. This can lower the barrier to the use of automation in products that might not otherwise feature APIs for this purpose. RPA tools have strong technical similarities to graphical user interface testing tools. These tools also automate interactions with the GUI, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

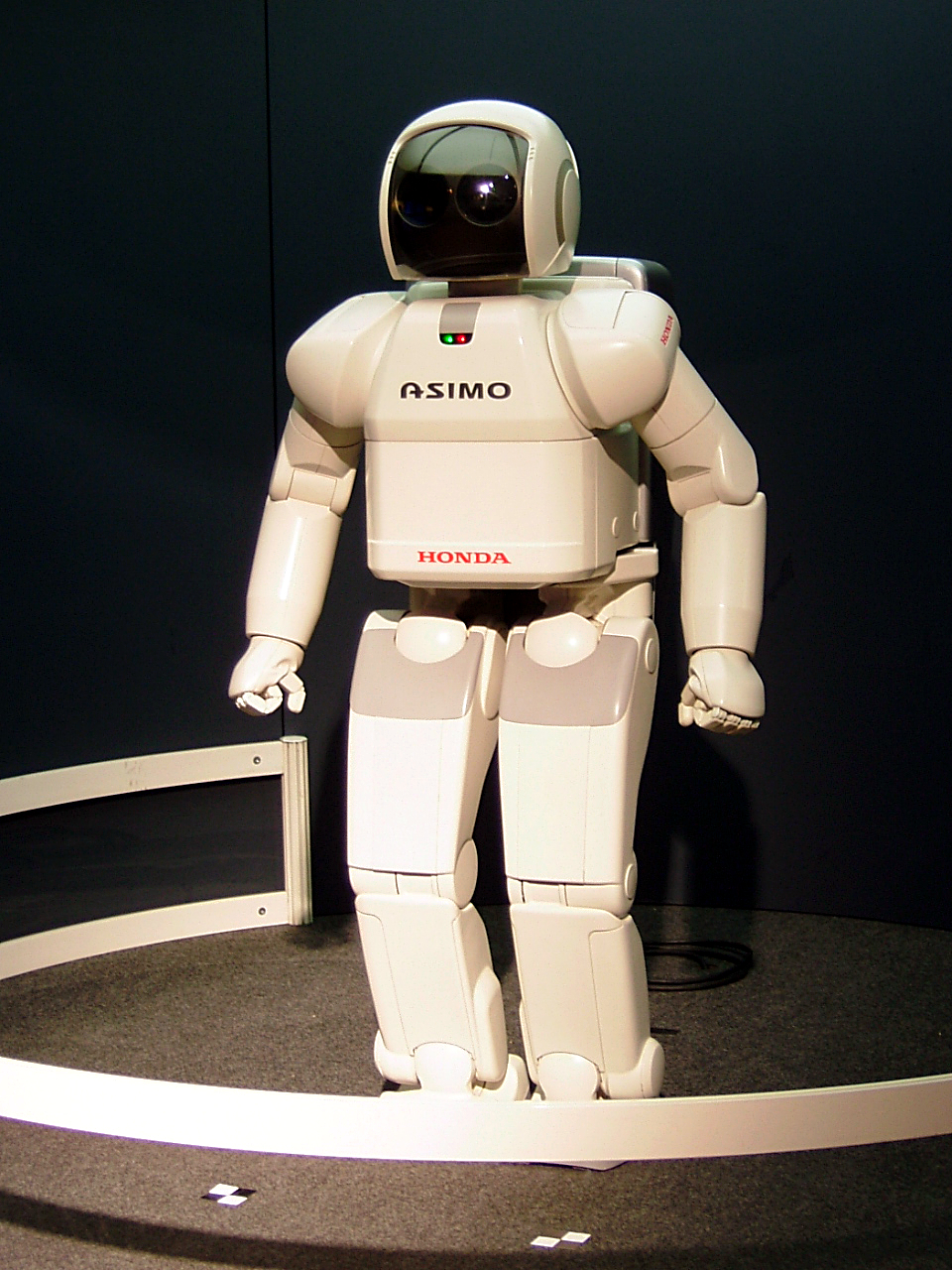

Robot

A robot is a machine—especially one programmable by a computer—capable of carrying out a complex series of actions automatically. A robot can be guided by an external control device, or the control may be embedded within. Robots may be constructed to evoke human form, but most robots are task-performing machines, designed with an emphasis on stark functionality, rather than expressive aesthetics. Robots can be autonomous or semi-autonomous and range from humanoids such as Honda's ''Advanced Step in Innovative Mobility'' ( ASIMO) and TOSY's ''TOSY Ping Pong Playing Robot'' ( TOPIO) to industrial robots, medical operating robots, patient assist robots, dog therapy robots, collectively programmed ''swarm'' robots, UAV drones such as General Atomics MQ-1 Predator, and even microscopic nano robots. By mimicking a lifelike appearance or automating movements, a robot may convey a sense of intelligence or thought of its own. Autonomous things are expected to prolif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automation

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision. Automation includes the use of various equipment and control systems such as machinery, processes in factories, boilers, and heat-treating ovens, switching on telephone networks, steering, and stabilization of ships, aircraft, and other applications and vehicles with reduced hu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burr (edge)

A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process. It is usually an unwanted piece of material and is removed with a deburring tool in a process called 'deburring'. Burrs are most commonly created by machining operations, such as grinding, drilling, milling, engraving or turning. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion of a surface; this type of burr is commonly formed when a hammer strikes a surface. Deburring accounts for a significant portion of manufacturing costs. In the printmaking technique of drypoint, burr, which gives a rich fuzzy quality to the engraved line, is highly desirable—the great problem with the drypoint medium is that the burr rapidly diminishes after as few as ten impressions are printed. Types There are three types of burrs that can be formed from machining operations: ''Poisson burr'', ''rollover burr'', and ''breako ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Productivity

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production process, i.e. output per unit of input, typically over a specific period of time. The most common example is the (aggregate) labour productivity measure, one example of which is GDP per worker. There are many different definitions of productivity (including those that are not defined as ratios of output to input) and the choice among them depends on the purpose of the productivity measurement and/or data availability. The key source of difference between various productivity measures is also usually related (directly or indirectly) to how the outputs and the inputs are aggregated to obtain such a ratio-type measure of productivity. Productivity is a crucial factor in the production performance of firms and nations. Increasing national producti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inventory Optimization

Inventory optimization is a method of balancing capital investment constraints or objectives and service-level goals over a large assortment of stock-keeping units (SKUs) while taking demand and supply volatility into account. Inventory management challenges Every company has the challenge of matching its supply volume to customer demand. How well the company manages this challenge has a major impact on its profitability. In contrast to the traditional "binge and purge" inventory cycle in which companies over-purchase product to prepare for possible demand spikes and then discards extra product, inventory optimization seeks to more efficiently match supply to expected customer demand. APQC Open Standards data shows that the median company carries an inventory of 10.6 percent of annual revenues as of 2011. The typical cost of carrying inventory is at least 10.0 percent of the inventory value. So the median company spends over 1 percent of revenues carrying inventory, although for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Return On Investment

Return on investment (ROI) or return on costs (ROC) is a ratio between net income (over a period) and investment (costs resulting from an investment of some resources at a point in time). A high ROI means the investment's gains compare favourably to its cost. As a performance measure, ROI is used to evaluate the efficiency of an investment or to compare the efficiencies of several different investments.Return On Investment – ROI , Investopedia as accessed 8 January 2013 In economic terms, it is one way of relating profits to capital invested. Purpose In business, the pur ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |