|

Misrun

A casting defect is an undesired irregularity in a metal casting process. Some defects can be tolerated while others can be repaired, otherwise they must be eliminated. They are broken down into five main categories: ''gas porosity'', ''shrinkage defects'', ''mould material defects'', ''pouring metal defects'', and ''metallurgical defects''. Terminology The terms "defect" and "" refer to two specific and separate things in castings. Defects are defined as conditions in a casting that must be corrected or removed, or the casting must be rejected. Discontinuities, also known as "imperfections", are defined as "interruptions in the physical continuity of the casting". Therefore, if the casting is less than perfect, but still useful and in tolerance, the imperfections should be deemed "discontinuities". Types There are many types of defects which result from many different causes. Some of the solutions to certain defects can be the cause for another type of defect. The following def ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pipe (casting)

A casting defect is an undesired irregularity in a metal casting process. Some defects can be tolerated while others can be repaired, otherwise they must be eliminated. They are broken down into five main categories: ''gas porosity'', ''shrinkage defects'', ''mould material defects'', ''pouring metal defects'', and ''metallurgical defects''. Terminology The terms "defect" and "" refer to two specific and separate things in castings. Defects are defined as conditions in a casting that must be corrected or removed, or the casting must be rejected. Discontinuities, also known as "imperfections", are defined as "interruptions in the physical continuity of the casting". Therefore, if the casting is less than perfect, but still useful and in tolerance, the imperfections should be deemed "discontinuities". Types There are many types of defects which result from many different causes. Some of the solutions to certain defects can be the cause for another type of defect. The following de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Entrapment

A casting defect is an undesired irregularity in a metal casting process. Some defects can be tolerated while others can be repaired, otherwise they must be eliminated. They are broken down into five main categories: ''gas porosity'', ''shrinkage defects'', ''mould material defects'', ''pouring metal defects'', and ''metallurgical defects''. Terminology The terms "defect" and "" refer to two specific and separate things in castings. Defects are defined as conditions in a casting that must be corrected or removed, or the casting must be rejected. Discontinuities, also known as "imperfections", are defined as "interruptions in the physical continuity of the casting". Therefore, if the casting is less than perfect, but still useful and in tolerance, the imperfections should be deemed "discontinuities". Types There are many types of defects which result from many different causes. Some of the solutions to certain defects can be the cause for another type of defect. The following def ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting (metalworking)

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a Mold (manufacturing), mold (usually by a crucible) that contains a negative impression (i.e., a three-dimensional negative image) of the intended shape. The metal is poured into the mold through a hollow channel called a Sprue (manufacturing), sprue. The metal and mold are then cooled, and the metal part (the ''casting'') is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods. Casting processes have been known for thousands of years, and have been widely used for sculpture (especially in bronze), jewelry in precious metals, and weapons and tools. Highly engineered castings are found in 90 percent of durable goods, including cars, trucks, aerospace, trains, mining and construction equipment, oil wells, appliances, pipes, hydrants, wind turbines, nuclear plants, medical devices, defense products, toys, an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shrinkage (casting)

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold (usually by a crucible) that contains a negative impression (i.e., a three-dimensional negative image) of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part (the ''casting'') is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods. Casting processes have been known for thousands of years, and have been widely used for sculpture (especially in bronze), jewelry in precious metals, and weapons and tools. Highly engineered castings are found in 90 percent of durable goods, including cars, trucks, aerospace, trains, mining and construction equipment, oil wells, appliances, pipes, hydrants, wind turbines, nuclear plants, medical devices, defense products, toys, and more. Traditional techniques include los ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atmosphere

An atmosphere () is a layer of gases that envelop an astronomical object, held in place by the gravity of the object. A planet retains an atmosphere when the gravity is great and the temperature of the atmosphere is low. A stellar atmosphere is the outer region of a star, which includes the layers above the opaque photosphere; stars of low temperature might have outer atmospheres containing compound molecules. The atmosphere of Earth is composed of nitrogen (78%), oxygen (21%), argon (0.9%), carbon dioxide (0.04%) and trace gases. Most organisms use oxygen for respiration; lightning and bacteria perform nitrogen fixation which produces ammonia that is used to make nucleotides and amino acids; plants, algae, and cyanobacteria use carbon dioxide for photosynthesis. The layered composition of the atmosphere minimises the harmful effects of sunlight, ultraviolet radiation, solar wind, and cosmic rays and thus protects the organisms from genetic damage. The curr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Flushing

Gas is a state of matter that has neither a fixed volume nor a fixed shape and is a compressible fluid. A ''pure gas'' is made up of individual atoms (e.g. a noble gas like neon) or molecules of either a single type of atom ( elements such as oxygen) or from different atoms ( compounds such as carbon dioxide). A ''gas mixture'', such as air, contains a variety of pure gases. What distinguishes gases from liquids and solids is the vast separation of the individual gas particles. This separation can make some gases invisible to the human observer. The gaseous state of matter occurs between the liquid and plasma states, the latter of which provides the upper-temperature boundary for gases. Bounding the lower end of the temperature scale lie degenerative quantum gases which are gaining increasing attention. High-density atomic gases super-cooled to very low temperatures are classified by their statistical behavior as either Bose gases or Fermi gases. For a comprehensive listing of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

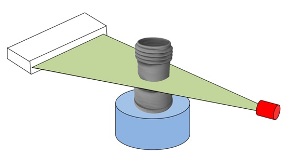

Industrial CT Scanning

Industrial computed tomography (CT) scanning is any computer-aided tomographic process, usually X-ray computed tomography, that uses irradiation to produce three-dimensional internal and external representations of a scanned object. Industrial CT scanning has been used in many areas of industry for internal inspection of components. Some of the key uses for industrial CT scanning have been flaw detection, failure analysis, metrology, assembly analysis and reverse engineering applications. Just as in medical imaging, industrial imaging includes both nontomographic radiography (industrial radiography) and computed tomographic radiography (computed tomography). Types of scanners ''Line beam scanning'' is the traditional process of industrial CT scanning.Hofmann, J., Flisch, A., Obrist, A., Adaptive CT scanning-mesh based optimisation methods for industrial X-ray computer tomography applications. NDT&E International (37), 2004, pp. 271–278. X-rays are produced and the beam is co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |