|

Hot Stamping

Hot stamping or foil stamping is a printing method of relief printing in which pre-dried ink or foils are transferred to a surface at high temperatures. The method has diversified since its rise to prominence in the 19th century to include a variety of processes. After the 1970s, hot stamping became one of the most important methods of decoration on the surface of plastic products. Process In a hot stamping machine, a die is mounted and heated, with the product to be stamped placed beneath it. A metallized or painted roll-leaf carrier is inserted between the two, and the die presses down through it. The dry paint or foil used is impressed into the surface of the product. The dye-stamping process itself is non-polluting because the materials involved are dry. Pressure and heat cause the relevant sections of the foil to become detached from the carrier material and become bonded with the printing surface. Tools Along with foil stamping machines, among the commonly used tools in ho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Relief Printing

Relief printing is a family of printing methods where a printing block, plate or matrix, which has had ink applied to its non-recessed surface, is brought into contact with paper. The non-recessed surface will leave ink on the paper, whereas the recessed areas will not. A printing press may not be needed, as the back of the paper can be rubbed or pressed by hand with a simple tool such as a brayer or roller. In contrast, in intaglio printing, the ''recessed'' areas are printed. Relief printing is one of the traditional families of printmaking techniques, along with the intaglio and planographic families, though modern developments have created others. In the relief family of printing, the matrix was historically made subtractively, by removing material from the surface of areas not intended to be printed. The remaining surface would then receive ink. The relief family of techniques includes woodcut, metalcut, wood engraving, relief etching, linocut, rubber stamp, foam pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies (used in the manufacture of wire) and casting dies (used in molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two die cutting operations, and bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force ( compression, tension, or both) and rely on the material's mechanical properties. Forming dies are typically made by tool and die makers and put into production after mounting into a pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various ''time setting'' materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper Embossing

Embossing and debossing are the processes of creating either raised or recessed relief images and designs in paper and other materials. An embossed pattern is raised against the background, while a debossed pattern is sunken into the surface of the material but might protrude somewhat on the reverse side. Techniques Often used in combination with foil stamping, embossing alters the surface of paper stock or other substrates by providing a three-dimensional or raised effect on selected areas. The procedure requires the use of two dies: one that is raised and one that is recessed. The dies fit into each other so that when the paper is pressed between them, the raised die forces the stock into the recessed die and creates the embossed impression. A specific level of pressure is applied to the dies in order to squeeze the fibers of the paper, which results in a permanently raised area in the paper. When the dies are produced, a die maker engraves the desired image into several me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

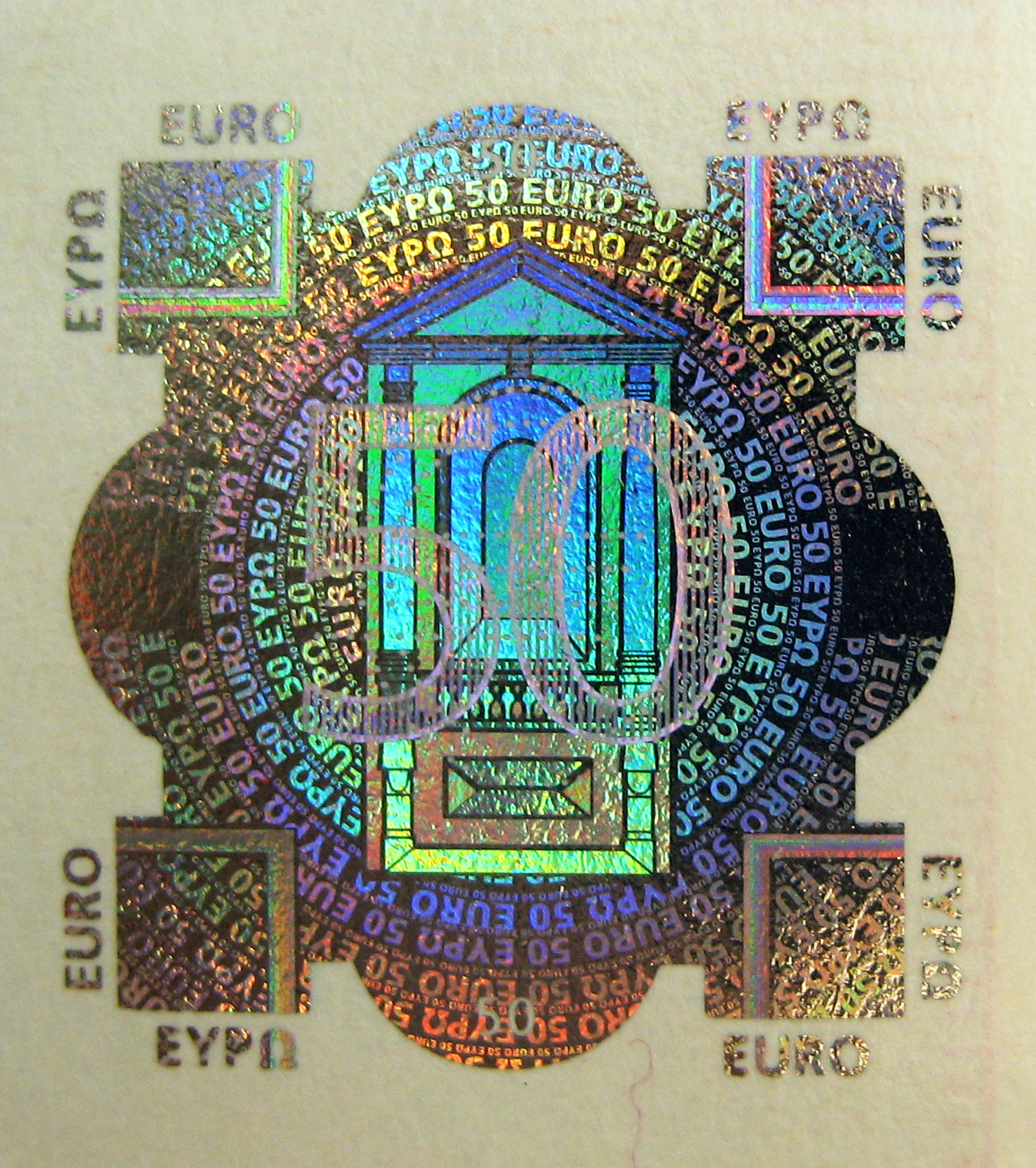

Security Printing

Security printing is the field of the printing industry that deals with the printing of items such as banknotes, cheques, passports, tamper-evident labels, security tapes, product authentication, stock certificates, postage stamps and identity cards. The main goal of security printing is to prevent forgery, tampering, or counterfeiting. More recently many of the techniques used to protect these high-value documents have become more available to commercial printers, whether they are using the more traditional offset and flexographic presses or the newer digital platforms. Businesses are protecting their lesser-value documents such as transcripts, coupons and prescription pads by incorporating some of the features listed below to ensure that they cannot be forged or that alteration of the data cannot occur undetected. A number of technical methods are used in the security printing industry. Security printing is most often done on security paper, but it can also occur on plastic m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radio-frequency Identification

Radio-frequency identification (RFID) uses electromagnetic fields to automatically Automatic identification system, identify and Tracking system, track tags attached to objects. An RFID system consists of a tiny radio transponder, a radio receiver and transmitter. When triggered by an electromagnetic interrogation pulse from a nearby RFID reader device, the tag transmits digital data, usually an Identifier, identifying inventory number, back to the reader. This number can be used to track inventory goods. Passive tags are powered by energy from the RFID reader's interrogating radio waves. Active tags are powered by a battery and thus can be read at a greater range from the RFID reader, up to hundreds of meters. Unlike a barcode, the tag does not need to be within the Line-of-sight propagation, line of sight of the reader, so it may be embedded in the tracked object. RFID is one method of automatic identification and data capture (AIDC). RFID tags are used in many industries. For e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Foil Printing

Cold foil printing, also known as cold foil stamping, is a modern method of printing metallic foil on a substrate in order to enhance the aesthetic of the final product. Cold foil printing can be done two ways: the older dry lamination process common in the offset printing industry, or the newer, more versatile wet lamination process, which is dominant in the flexo label industry. How it works Cold foil dry lamination Using a standard printing plate, an image is printed onto a substrate with the use of an ultraviolet-curable cold foil adhesive. An ultraviolet dryer then cures the adhesive, which becomes tacky. Foil spools from an unwind and is nipped to a substrate. Foil sticks to the tacky adhesive on the substrate, and an image with a bright foil surface is created. Foil that does not adhere to the adhesive remains on a thin polyester liner, and waste is directed to a rewind spool. Because the adhesive is applied on press like a conventional ink, no expensive stamping die has to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pad Printing

Pad printing (also called tampography) is a printing process that can transfer a 2-D image onto a 3-D object (e.g. a ceramic pottery). This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate. Pad printing is used for printing on otherwise difficult to print on products in many industries including medical, automotive, promotional, apparel, and electronic objects, as well as appliances, sports equipment and toys. It can also be used to deposit functional materials such as conductive inks, adhesives, dyes and lubricants. Physical changes within the ink film both on the cliché and on the pad allow it to leave the etched image area in favor of adhering to the pad, and to subsequently release from the pad in favor of adhering to the substrate. The unique properties of the silicone pad enable it to pick the image up from a flat plane and transfer it to a variety of surfa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |