|

Fluidized Bed Reactor

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst) at high enough speeds to suspend the solid and cause it to behave as though it were a fluid. This process, known as fluidization, imparts many important advantages to an FBR. As a result, FBRs are used for many industrial applications. Basic principles The solid substrate material (the catalytic material upon which chemical species react) in the fluidized bed reactor is typically supported by a porous plate, known as a distributor.Howard, J. R. (1989). ''Fluidized Bed Technology: Principles and Applications.'' New York, NY: Adam Higler. The fluid is then forced through the distributor up through the solid material. At lower fluid velocities, the solids remain in place as the fluid passes through the voids in the material. This is known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluidized Bed

A fluidized bed is a physical phenomenon that occurs when a solid particulate substance (usually present in a holding vessel) is under the right conditions so that it behaves like a fluid. The usual way to achieve a fluidize bed is to pump pressurized fluid into the particles. The resulting medium then has many properties and characteristics of normal fluids, such as the ability to free-flow under gravity, or to be pumped using fluid technologies. The resulting phenomenon is called fluidization. Fluidized beds are used for several purposes, such as fluidized bed reactors (types of chemical reactors), solids separation, fluid catalytic cracking, fluidized bed combustion, heat or mass transfer or interface modification, such as applying a coating onto solid items. This technique is also becoming more common in aquaculture for the production of shellfish in integrated multi-trophic aquaculture systems. Properties A fluidized bed consists of fluid-solid mixture that exhibits fluid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Thailand, Malaysia, and Indonesia are three of the leading rubber producers. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the rubber tree (''Hevea brasiliensis'') or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". The latex then is refined into the rubber that is ready for commercial processing. In major areas, latex is allowed to coagulate in the collection cup. The coagulated lumps are collected and processed into dry forms for sale. Natural rubber is used extensively in many applications and products, either alone or in combination ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pilot Plant

A pilot plant is a pre-commercial production system that employs new production technology and/or produces small volumes of new technology-based products, mainly for the purpose of learning about the new technology. The knowledge obtained is then used for design of full-scale production systems and commercial products, as well as for identification of further research objectives and support of investment decisions. Other (non-technical) purposes include gaining public support for new technologies and questioning government regulations. Pilot plant is a relative term in the sense that pilot plants are typically smaller than full-scale production plants, but are built in a range of sizes. Also, as pilot plants are intended for learning, they typically are more flexible, possibly at the expense of economy. Some pilot plants are built in laboratories using stock lab equipment, while others require substantial engineering efforts, cost millions of dollars, and are custom-assembled and f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Entrainment (engineering)

:''See entrainment for other types.'' In engineering, entrainment is the entrapment of one substance by another substance. For example: * The entrapment of liquid droplets or solid particulates in a flowing gas, as with smoke. * The entrapment of gas bubbles or solid particulates in a flowing liquid, as with aeration. * Given two mutually insoluble liquids, the emulsion of droplets of one liquid into the other liquid, as with margarine. * Given two gases, the entrapment of one gas into the other gas. * "Air entrainment Air entrainment in concrete is the intentional creation of tiny air bubbles in a batch by adding an air entraining agent during mixing. A form of surfactant (a surface-active substance that in the instance reduces the surface tension between wa ..." - The intentional entrapment of air bubbles into concrete. * Entrainment defect in metallurgy, as a result of folded pockets of oxide inside the melt. See also * Souders-Brown equation References Chemical en ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Drop

Pressure drop is defined as the difference in total pressure between two points of a fluid carrying network. A pressure drop occurs when frictional forces, caused by the resistance to flow, act on a fluid as it flows through the tube. The main determinants of resistance to fluid flow are fluid velocity through the pipe and fluid viscosity. Pressure drop increases proportionally to the frictional shear forces within the piping network. A piping network containing a high relative roughness rating as well as many pipe fittings and joints, tube convergence, divergence, turns, surface roughness, and other physical properties will affect the pressure drop. High flow velocities and/or high fluid viscosities result in a larger pressure drop across a section of pipe or a valve or elbow. Low velocity will result in lower or no pressure drop. The fluid may also be biphasic as in pneumatic conveying with a gas and a solid, in this case, the friction of the solid must also be taken into cons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Batch Reactor

The batch reactor is the generic term for a type of vessel widely used in the process industries. Its name is something of a misnomer since vessels of this type are used for a variety of process operations such as solids dissolution, product mixing, chemical reactions, batch distillation, crystallization, liquid/liquid extraction and polymerization. In some cases, they are not referred to as reactors but have a name which reflects the role they perform (such as crystallizer, or bioreactor). A typical batch reactor consists of a storage tank with an agitator and integral heating/cooling system. These vessels may vary in size from less than 1 litre to more than 15,000 litres. They are usually fabricated in steel, stainless steel, glass-lined steel, glass or exotic alloy. Liquids and solids are usually charged via connections in the top cover of the reactor. Vapors and gases also discharge through connections in the top. Liquids are usually discharged out of the bottom. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuous Production

Continuous production is a flow production method used to manufacture, produce, or process materials without interruption. Continuous production is called a continuous process or a continuous flow process because the materials, either dry bulk or fluids that are being processed are continuously in motion, undergoing chemical reactions or subject to mechanical or heat treatment. Continuous processing is contrasted with batch production. Continuous usually means operating 24 hours per day, seven days per week with infrequent maintenance shutdowns, such as semi-annual or annual. Some chemical plants can operate for more than one to two years without a shutdown. Blast furnaces can run from four to ten years without stopping. Common processes Some common continuous processes are the following: * Oil refining *Chemicals * Synthetic fibers *Fertilizers *Pulp and paper * Blast furnace (iron) *Metal smelting *Power stations * Natural gas processing *Sanitary waste water treatment ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

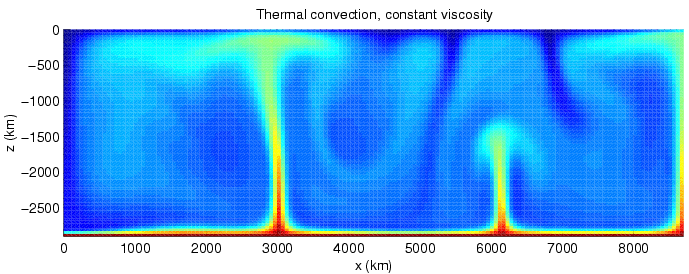

Heat Transfer

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species (mass transfer in the form of advection), either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system. Heat conduction, also called diffusion, is the direct microscopic exchanges of kinetic energy of particles (such as molecules) or quasiparticles (such as lattice waves) through the boundary between two systems. When an object is at a different temperature from another body or its surroundings, heat flows so that the body and the surroundings reach the same temperature, at which point they are in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exothermic

In thermodynamics, an exothermic process () is a thermodynamic process or reaction that releases energy from the system to its surroundings, usually in the form of heat, but also in a form of light (e.g. a spark, flame, or flash), electricity (e.g. a battery), or sound (e.g. explosion heard when burning hydrogen). The term ''exothermic'' was first coined by 19th-century French chemist Marcellin Berthelot. The opposite of an exothermic process is an endothermic process, one that absorbs energy usually in the form of heat. The concept is frequently applied in the physical sciences to chemical reactions where chemical bond energy is converted to thermal energy (heat). Two types of chemical reactions Exothermic and endothermic describe two types of chemical reactions or systems found in nature, as follows: Exothermic After an exothermic reaction, more energy has been released to the surroundings than was absorbed to initiate and maintain the reaction. An example would be t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gradients

In vector calculus, the gradient of a scalar-valued differentiable function of several variables is the vector field (or vector-valued function) \nabla f whose value at a point p is the "direction and rate of fastest increase". If the gradient of a function is non-zero at a point , the direction of the gradient is the direction in which the function increases most quickly from , and the magnitude of the gradient is the rate of increase in that direction, the greatest absolute directional derivative. Further, a point where the gradient is the zero vector is known as a stationary point. The gradient thus plays a fundamental role in optimization theory, where it is used to maximize a function by gradient ascent. In coordinate-free terms, the gradient of a function f(\bf) may be defined by: :df=\nabla f \cdot d\bf where ''df'' is the total infinitesimal change in ''f'' for an infinitesimal displacement d\bf, and is seen to be maximal when d\bf is in the direction of the gra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coal Gasification

Coal gasification is the process of producing syngas—a mixture consisting primarily of carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2), methane (CH4), and water vapour (H2O)—from coal and water, air and/or oxygen. Historically, coal was gasified to produce coal gas, also known as "town gas". Coal gas is combustible and was used for heating and municipal lighting, before the advent of large-scale extraction of natural gas from oil wells. In current practice, large-scale coal gasification installations are primarily for electricity generation (both in conventional thermal power stations and molten carbonate fuel cell power stations), or for production of chemical feedstocks. The hydrogen obtained from coal gasification can be used for various purposes such as making ammonia, powering a hydrogen economy, or upgrading fossil fuels. Alternatively, coal-derived syngas can be converted into transportation fuels such as gasoline and diesel through additional treatment ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerizat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |