|

Fracture

Fracture is the appearance of a crack or complete separation of an object or material into two or more pieces under the action of stress (mechanics), stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band, or dislocation. #Brittle, Brittle fractures occur without any apparent deformation before fracture. #Ductile, Ductile fractures occur after visible deformation. Fracture strength, or breaking strength, is the stress when a specimen fails or fractures. The detailed understanding of how a fracture occurs and develops in materials is the object of fracture mechanics. Strength Fracture strength, also known as breaking strength, is the stress at which a specimen structural integrity and failure, fails via fra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture Mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture. Theoretically, the stress ahead of a sharp crack tip becomes infinite and cannot be used to describe the state around a crack. Fracture mechanics is used to characterise the loads on a crack, typically using a single parameter to describe the complete loading state at the crack tip. A number of different parameters have been developed. When the plastic zone at the tip of the crack is small relative to the crack length the stress state at the crack tip is the result of elastic forces within the material and is termed linear elastic fracture mechanics (LEFM) and can be characterised using the stress intensity factor K. Although the load on a crack can be arbitrary, in 1957 G. Irwin foun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture Toughness

In materials science, fracture toughness is the critical stress intensity factor of a sharp Fracture, crack where propagation of the crack suddenly becomes rapid and unlimited. It is a material property that quantifies its ability to resist crack propagation and failure under applied stress. A component's thickness affects the constraint conditions at the tip of a crack with thin components having plane stress conditions, leading to ductile behavior and thick components having plane strain conditions, where the constraint increases, leading to brittle failure. Plane strain conditions give the lowest fracture toughness value which is a material properties, material property. The critical value of stress intensity factor in Fracture mechanics, mode I loading measured under plane strain conditions is known as the plane strain fracture toughness, denoted K_\text. When a test fails to meet the thickness and other test requirements that are in place to ensure plane strain conditions, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conchoidal Fracture

A conchoidal fracture is a break or fracture of a brittle material that does not follow any natural planes of separation. Mindat.org defines ''conchoidal fracture'' as follows: "a fracture with smooth, curved surfaces, typically slightly concave, showing concentric undulations resembling the lines of growth of a shell".Conchoidal fracture at Mindat.org Materials that break in this way include , chert, , [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic deformation, which is reversible upon removing the stress. Ductility is a critical mechanical performance indicator, particularly in applications that require materials to bend, stretch, or deform in other ways without breaking. The extent of ductility can be quantitatively assessed using the percent elongation at break, given by the equation: \% \mathrm= \left ( \frac \right )\times100 where l_ is the length of the material after fracture and l_0 is the original length before testing. This formula helps in quantifying how much a material can stretch under tensile stress before failure, providing key insights into its ductile behavior. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitabil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductile Fracture Upd

Ductility refers to the ability of a material to sustain significant plastic deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic deformation, which is reversible upon removing the stress. Ductility is a critical mechanical performance indicator, particularly in applications that require materials to bend, stretch, or deform in other ways without breaking. The extent of ductility can be quantitatively assessed using the percent elongation at break, given by the equation: \% \mathrm= \left ( \frac \right )\times100 where l_ is the length of the material after fracture and l_0 is the original length before testing. This formula helps in quantifying how much a material can stretch under tensile stress before failure, providing key insights into its ductile behavior. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufactur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brittleness

A material is brittle if, when subjected to stress (physics), stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength of materials, strength. Breaking is often accompanied by a sharp snapping sound. When used in materials science, it is generally applied to materials that fail when there is little or no plasticity (physics), plastic deformation before failure. One proof is to match the broken halves, which should fit exactly since no plastic deformation has occurred. Brittleness in different materials Polymers Mechanical characteristics of polymers can be sensitive to temperature changes near room temperatures. For example, poly(methyl methacrylate) is extremely brittle at temperature 4˚C, but experiences increased ductility with increased temperature. Amorphous polymers are polymers that can behave differently at different temperatures. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick. The earliest ceramics made by humans were fired clay bricks used for building house walls and other structures. Other pottery objects such as pots, vessels, vases and figurines were made from clay, either by itself or mixed with other materials like silica, hardened by sintering in fire. Later, ceramics were glazed and fired to create smooth, colored surfaces, decreasing porosity through the use of glassy, amorphous ceramic coatings on top of the crystalline ceramic substrates. Ceramics now include domestic, industrial, and building products, as well as a wide range of materials developed for use in advanced ceramic engineering, such as semiconductors. The word '' ceramic'' comes from the Ancient Greek word (), meaning ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brittle

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a sharp snapping sound. When used in materials science, it is generally applied to materials that fail when there is little or no plastic deformation before failure. One proof is to match the broken halves, which should fit exactly since no plastic deformation has occurred. Brittleness in different materials Polymers Mechanical characteristics of polymers can be sensitive to temperature changes near room temperatures. For example, poly(methyl methacrylate) is extremely brittle at temperature 4˚C, but experiences increased ductility with increased temperature. Amorphous polymers are polymers that can behave differently at different temperatures. They may behave like a glass at low temperatures (the gla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supersonic Fracture

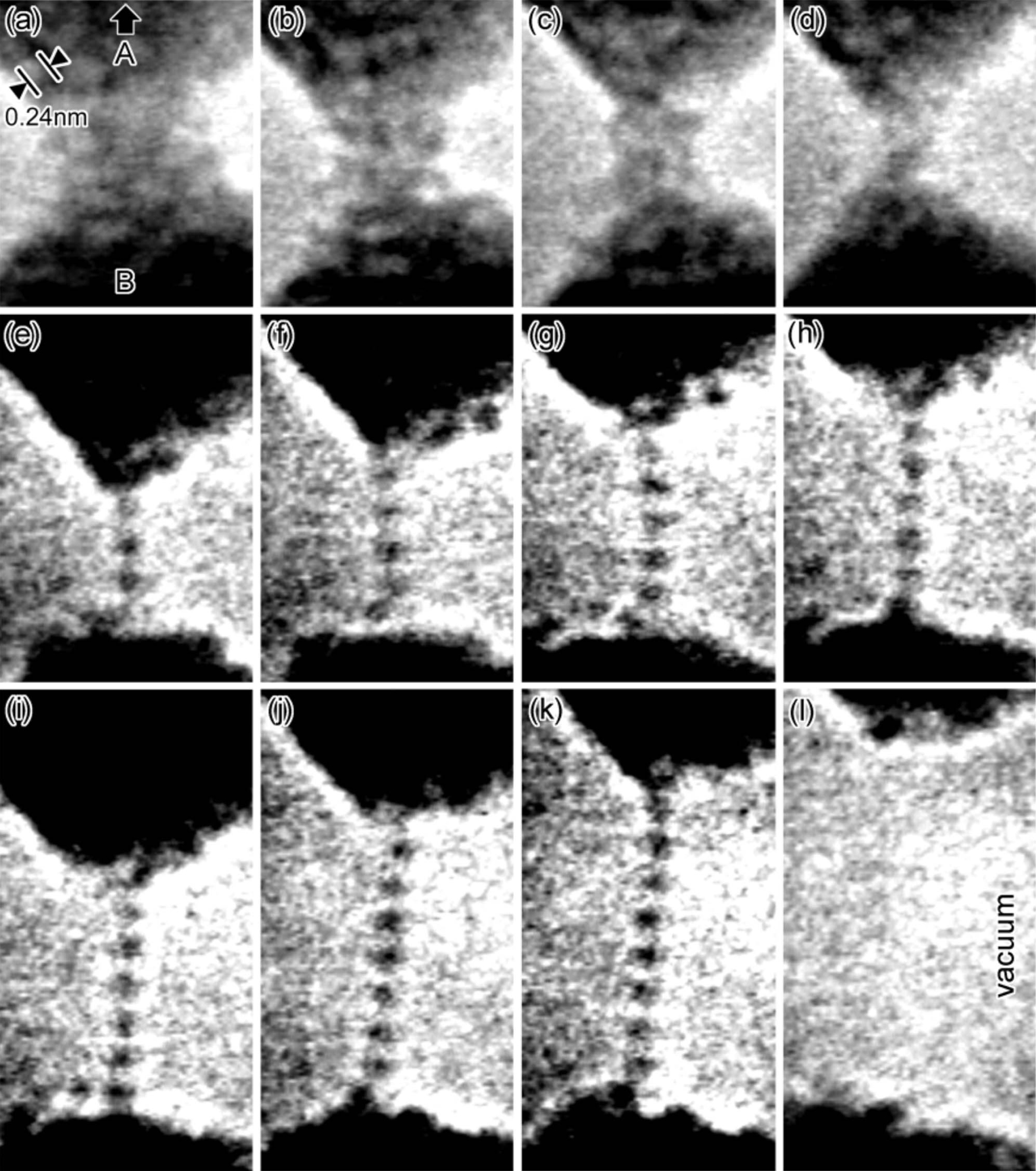

Supersonic fractures are fractures where the fracture propagation velocity is higher than the speed of sound in the material. This phenomenon was first discovered by scientists from the Max Planck Institute for Metals Research in Stuttgart ( Markus J. Buehler and Huajian Gao) and IBM Almaden Research Center in San Jose, California ( Farid F. Abraham). The issues of intersonic and supersonic fracture become the frontier of dynamic fracture mechanics. The work of Burridge initiated the exploration for intersonic crack growth (when the crack tip velocity V is between the shear in wave speed C^8 and the longitudinal wave speed C^1. Eurekalert.org. Accessed May 19, 2012. Supersonic fracture was a phenomenon totally unexplained by the classical theories of fracture. |

Structural Integrity And Failure

Structural integrity and failure is an aspect of engineering that deals with the ability of a structure to support a designed structural load (weight, force, etc.) without breaking and includes the study of past structural failures in order to prevent failures in future designs. Structural integrity is the ability of an item—either a structural component or a structure consisting of many components—to hold together under a load, including its own weight, without breaking or deforming excessively. It assures that the construction will perform its designed function during reasonable use, for as long as its intended life span. Items are constructed with structural integrity to prevent catastrophic failure, which can result in injuries, severe damage, death, and/or monetary losses. ''Structural failure'' refers to the loss of structural integrity, or the loss of load-carrying structural capacity in either a structural component or the structure itself. Structural failure is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress–strain Curve

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain. It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined (see tensile testing). These curves reveal many of the properties of a material, such as the Young's modulus, the yield strength and the ultimate tensile strength. Definition Generally speaking, curves that represent the relationship between stress and strain in any form of deformation can be regarded as stress–strain curves. The stress and strain can be normal, shear, or a mixture, and can also be uniaxial, biaxial, or multiaxial, and can even change with time. The form of deformation can be compression, stretching, torsion, rotation, and so on. If not mentioned otherwise, stress–strain curve typically refers to the relationship between axial normal stress and axial normal strain of materials measur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |