|

Drilled

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off chips (swarf) from the hole as it is drilled. In rock drilling, the hole is usually not made through a circular cutting motion, though the bit is usually rotated. Instead, the hole is usually made by hammering a drill bit into the hole with quickly repeated short movements. The hammering action can be performed from outside the hole ( top-hammer drill) or within the hole ( down-the-hole drill, DTH). Drills used for horizontal drilling are called drifter drills. In rare cases, specially-shaped bits are used to cut holes of non-circular cross-section; a square cross-section is possible. Process Drilled holes are ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Bit

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: * The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Jig

A drill is a tool used for making round holes or driving fasteners. It is fitted with a drill bit for making holes, or a screwdriver bit for securing fasteners. Historically, they were powered by hand, and later mains power, but cordless battery-powered drills are proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, and utility projects. Specially designed versions are made for surgery, dentistry, miniatures, and other applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The earli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Residual Stress

In materials science and solid mechanics, residual stresses are stresses that remain in a solid material after the original cause of the stresses has been removed. Residual stress may be desirable or undesirable. For example, laser peening imparts deep beneficial compressive residual stresses into metal components such as turbine engine fan blades, and it is used in toughened glass to allow for large, thin, crack- and scratch-resistant glass displays on smartphones. However, unintended residual stress in a designed structure may cause it to fail prematurely. Residual stresses can result from a variety of mechanisms including inelastic (plastic) deformations, temperature gradients (during thermal cycle) or structural changes ( phase transformation). Heat from welding may cause localized expansion, which is taken up during welding by either the molten metal or the placement of parts being welded. When the finished weldment cools, some areas cool and contract more than others ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

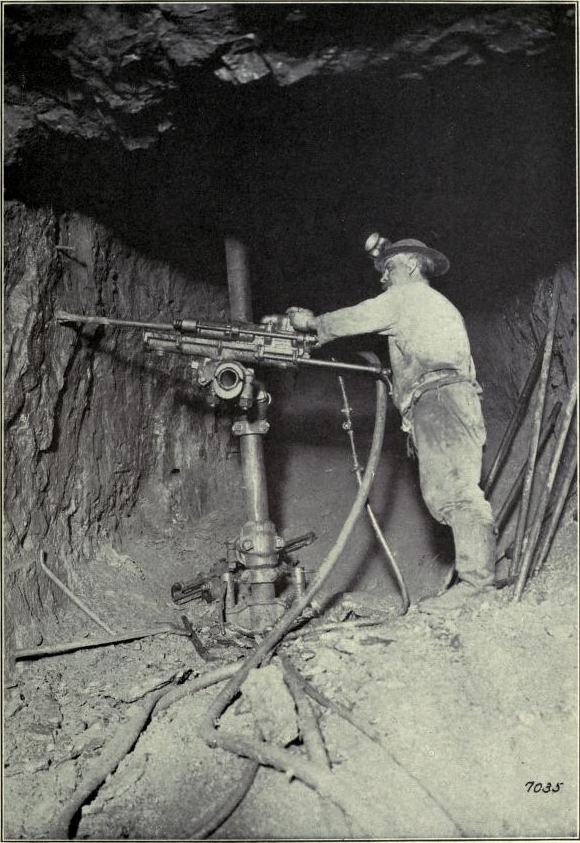

Drifter Drill

A drifter drill, sometimes called a rock drill, is a tool used in mining and civil engineering to drill into rock (geology), rock. Rock drills are used for making holes for placing dynamite or other explosives in rock blasting, and holes for plug and feather quarrying. While a rock drill may be as simple as a specialized form of chisel, it may also take the form of a powered machine. The mechanism may be worked or powered by hand, by steam, by compressed air (pneumatics), by Hydraulic machinery, hydraulics, or by electricity. Machine rock drills come in two basic forms: those that operate by percussion (using a reciprocating motion), and those that are abrasive (using a rotary motion, rotary motion). A smaller, hand-held percussion rock drill is considered a type of jackhammer. History and types The simplest form of rock drill consists of a long chisel or drill steel that was struck with a sledgehammer. Mark Twain, who worked unsuccessfully as a silver miner in the early 18 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burr (metal)

A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process. It is usually an unwanted piece of material and is removed with a deburring tool in a process called deburring. Burrs are most commonly created by machining operations, such as grinding, drilling, milling, engraving or turning. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion of a surface; this type of burr is commonly formed when a hammer strikes a surface. Deburring accounts for a significant portion of manufacturing costs. In the printmaking technique of drypoint, burr, which gives a rich fuzzy quality to the engraved line, is highly desirable—the great problem with the drypoint medium is that the burr rapidly diminishes after as few as ten impressions are printed. Types There are three types of burrs that can be formed from machining operations: ''Poisson burr'', ''rollover burr'', and ''breakout ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deflection (engineering)

In structural engineering, deflection is the degree to which a part of a long structural element (such as Beam (structure), beam) is deformation (mechanics), deformed laterally (in the direction transverse to its longitudinal axis) under a Structural load, load. It may be quantified in terms of an angle (angular displacement) or a distance (linear displacement (geometry), displacement). A longitudinal deformation (in the direction of the axis) is called ''elongation (mechanics), elongation''. The deflection distance of a member under a load can be calculated by Integral, integrating the function that mathematically describes the slope of the deflected shape of the member under that load. Standard formulas exist for the deflection of common Beam (structure), beam configurations and load cases at discrete locations. Otherwise methods such as virtual work, Direct integration of a beam, direct integration, Castigliano's method, Macaulay's method or the direct stiffness method are use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various time setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and develo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by metalsmith, smiths for millennia; the traditional products were kitchenware, household hardware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanism (engineering), mechanisms and machines wherever a component requires high strength of materials, strength; such forgings usually require further processing (such as machining) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molding (process)

Molding (American English) or moulding ( British and Commonwealth English; see spelling differences) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material. The liquid hardens or sets inside the mold, adopting its shape. A mold is a counterpart to a cast. The very common bi-valve molding process uses two molds, one for each half of the object. Articulated molds have multiple pieces that come together to form the complete mold, and then disassemble to release the finished casting; they are expensive, but necessary when the casting shape has complex overhangs. Piece-molding uses a number of different molds, each creating a section of a complicated object. This is generally only used for larg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |