|

Desulfurisation

Desulfurization or desulphurisation is a chemical process for the removal of sulfur from a material. The term usually refers to the removal of sulfur from a molecule or a material by hydrogenolysis: : Hydrogen is the ultimate sulfur acceptor. As applied to oil refinery streams, the conversion is known as hydrodesulfurization. These processes are of industrial and environmental importance as they provide the bulk of sulfur used in industry (Claus process and Contact process), sulfur-free compounds that could otherwise not be used in a great number of catalytic processes, and also reduce the release of harmful sulfur compounds into the environment. A laboratory scale hydrogenolysis is the desulfurization of thioketals by Raney nickel. In such cases, the hydrogen is contained within the reagent. Desulfurization without hydrogenolysis Desulfurization without hydrogenolysis is uncommon. Some trithiocarbonates can be coupled by desulfurization with phosphites or phosphines as S-ato ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wet Sulfuric Acid Process

The wet sulfuric acid process (WSA process) is a gas desulfurization process introduced by Danish company Haldor Topsoe in 1987. The WSA process can be applied in all industries where sulfur removal presents an issue, and produces commercial quality sulfuric acid (H2SO4) and high-pressure steam during desulfurization The wet catalysis process is used for processing sulfur-containing streams, such as: * H2S gas from e.g. amine gas treating unit * Off-gas from sour water stripper (SWS) gas *Off-gas from Rectisol *Spent acid from an alkylation unit * Claus process tail gas *Heavy residue or petcoke-fired utility boiler off-gas *Boiler flue gases from various processes SNOX flue gas desulfurization *Metallurgical process gas *Production of sulfuric acid The process ;The main reactions in the WSA process *Combustion: 2 H2S + 3 O2 2 H2O + 2 SO2 (-1036 kJ/mol) *Oxidation: 2 SO2 + O2 2 SO3 (-198 kJ/mol) Vanadium(V)_oxide.html" ;"title="n the presence of a Vanadium(V) oxide">va ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms form cyclic octatomic molecules with the chemical formula S8. Elemental sulfur is a bright yellow, crystalline solid at room temperature. Sulfur is the tenth most abundant element by mass in the universe and the fifth most common on Earth. Though sometimes found in pure, native form, sulfur on Earth usually occurs as sulfide and sulfate minerals. Being abundant in native form, sulfur was known in ancient times, being mentioned for its uses in ancient India, ancient Greece, China, and ancient Egypt. Historically and in literature sulfur is also called brimstone, which means "burning stone". Almost all elemental sulfur is produced as a byproduct of removing sulfur-containing contaminants from natural gas and petroleum.. Downloahere Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrogenolysis

Hydrogenolysis is a chemical reaction whereby a carbon–carbon or carbon–heteroatom single bond is cleaved or undergoes lysis (breakdown) by hydrogen.Ralph Connor, Homer Adkins. Hydrogenolysis Of Oxygenated Organic Compounds. J. Am. Chem. Soc.; 1932; 54(12); 4678–4690. The heteroatom may vary, but it usually is oxygen, nitrogen, or sulfur. A related reaction is hydrogenation, where hydrogen is added to the molecule, without cleaving bonds. Usually hydrogenolysis is conducted catalytically using hydrogen gas. History The term "hydrogenolysis" was coined by Carleton Ellis in reference to hydrogenolysis of carbon–carbon bonds. Earlier, Paul Sabatier had already observed the hydrogenolysis of benzyl alcohol to toluene, and as early as 1906, Padoa and Ponti had observed the hydrogenolysis of furfuryl alcohol. Homer Burton Adkins and Ralph Connor were the first to call the carbon–oxygen bond cleavage "hydrogenolysis". In the petrochemical industry In petroleum refineries ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Refinery

An oil refinery or petroleum refinery is an industrial processes, industrial process Factory, plant where petroleum (crude oil) is transformed and refining, refined into products such as gasoline (petrol), diesel fuel, Bitumen, asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha. Petrochemical feedstock like ethylene and propene, propylene can also be produced directly by Cracking (chemistry), cracking crude oil without the need of using refined products of crude oil such as naphtha. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products. In 2020, the total capacity of global refineries for crude oil was about 101.2 million barrels per day. Oil refineries are typically large, sprawling industrial complexes with extensive piping running throughout, carrying streams of fluids b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrodesulfurization

Hydrodesulfurization (HDS), also called hydrotreatment or hydrotreating, is a catalytic chemical process widely used to desulfurization, remove sulfur (S) from natural gas and from oil refinery, refined petroleum products, such as gasoline, gasoline or petrol, jet fuel, kerosene, diesel fuel, and fuel oils. The purpose of removing the sulfur, and creating products such as ultra-low-sulfur diesel, is to reduce the sulfur dioxide () emissions that result from using those fuels in automotive vehicles, aircraft, railroad locomotives, ships, gas or oil burning Fossil-fuel power station, power plants, residential and industrial furnaces, and other forms of fuel combustion. Another important reason for removing sulfur from the Petroleum naphtha, naphtha streams within a petroleum refinery is that sulfur, even in extremely low concentrations, catalyst poisoning, poisons the noble metal catalysts (platinum and rhenium) in the catalytic reforming units that are subsequently used to upgr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Claus Process

The Claus process is the most significant gas desulfurizing process, recovering elemental sulfur from gaseous hydrogen sulfide. First patented in 1883 by the chemist Carl Friedrich Claus, the Claus process has become the industry standard. The multi-step Claus process recovers sulfur from the gaseous hydrogen sulfide found in raw natural gas and from the by-product gases containing hydrogen sulfide derived from refining crude oil and other industrial processes. The by-product gases mainly originate from physical and chemical gas treatment units ( Selexol, Rectisol, Purisol and amine scrubbers) in refineries, natural gas processing plants and gasification or synthesis gas plants. These by-product gases may also contain hydrogen cyanide, hydrocarbons, sulfur dioxide or ammonia. Gases with an H2S content of over 25% are suitable for the recovery of sulfur in straight-through Claus plants while alternate configurations such as a split-flow set up or feed and air preheatin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Contact Process

The contact process is a method of producing sulfuric acid in the high concentrations needed for industrial processes. Platinum was originally used as the catalyst for this reaction; however, because it is susceptible to reacting with arsenic impurities in the sulfur feedstock, vanadium(V) oxide (V2O5) has since been preferred. History This process was patented in 1831 by British vinegar merchant Peregrine Phillips. In addition to being a far more economical process for producing concentrated sulfuric acid than the previous lead chamber process, the contact process also produces sulfur trioxide and oleum. In 1890 John Brown Francis Herreshoff developed a form of the contact catalytic process for the company of which he was a partner. In 1901 Eugen de Haën patented the basic process involving combining sulfur dioxide and oxygen in the presence of vanadium oxides, producing sulfur trioxide which was easily absorbed into water, producing sulfuric acid. This process was imp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalysis

Catalysis () is the increase in rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst. The rate increase occurs because the catalyst allows the reaction to occur by an alternative mechanism which may be much faster than the noncatalyzed mechanism. However the noncatalyzed mechanism does remain possible, so that the total rate (catalyzed plus noncatalyzed) can only increase in the presence of the catalyst and never decrease. Catalysis may be classified as either homogeneous, whose components are dispersed in the same phase (usual ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

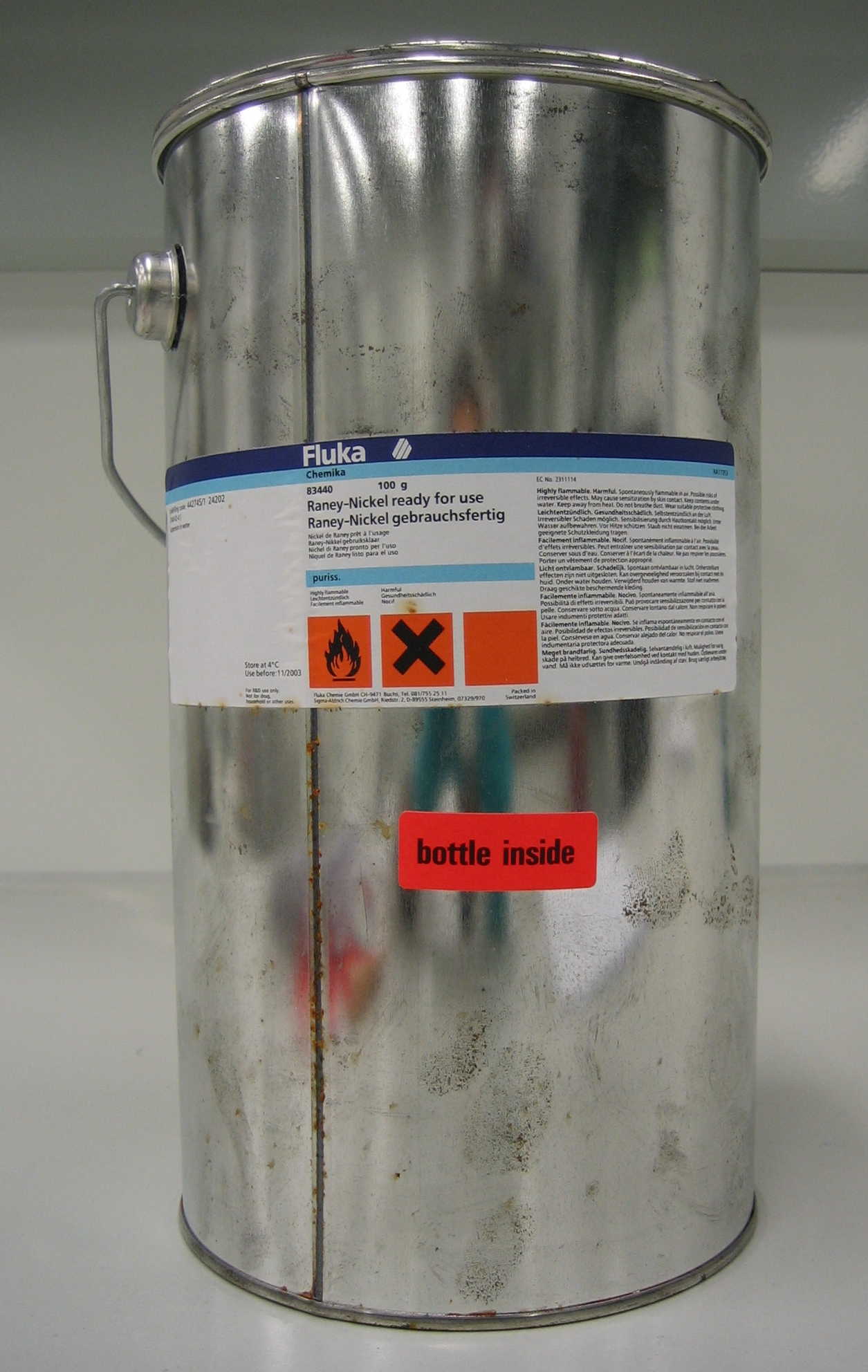

Raney Nickel

Raney nickel , also called spongy nickel, is a fine-grained solid composed mostly of nickel derived from a nickel–aluminium alloy. Several grades are known, of which most are gray solids. Some are pyrophoric, but most are used as air-stable slurries. Raney nickel is used as a reagent and as a catalyst in organic chemistry. It was developed in 1926 by American engineer Murray Raney for the hydrogenation of vegetable oils. Raney Nickel is a registered trademark of W. R. Grace and Company. Other major producers are Evonik and Johnson Matthey. Preparation Alloy preparation The Ni–Al alloy is prepared by dissolving nickel in molten aluminium followed by cooling ("quenching"). Depending on the Ni:Al ratio, quenching produces a number of different phases. During the quenching procedure, small amounts of a third metal, such as zinc or chromium, are added to enhance the activity of the resulting catalyst. This third metal is called a "Promoter (catalysis), promoter". The promoter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Desulfurization Of Thioacetal Using Raney Ni (cropped)

Desulfurization or desulphurisation is a chemical process for the removal of sulfur from a material. The term usually refers to the removal of sulfur from a molecule or a material by hydrogenolysis: : Hydrogen is the ultimate sulfur acceptor. As applied to oil refinery streams, the conversion is known as hydrodesulfurization. These processes are of industrial and environmental importance as they provide the bulk of sulfur used in industry (Claus process and Contact process), sulfur-free compounds that could otherwise not be used in a great number of catalytic processes, and also reduce the release of harmful sulfur compounds into the environment. A laboratory scale hydrogenolysis is the desulfurization of thioketals by Raney nickel. In such cases, the hydrogen is contained within the reagent. Desulfurization without hydrogenolysis Desulfurization without hydrogenolysis is uncommon. Some trithiocarbonates can be coupled by desulfurization with phosphites or phosphines as S-ato ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phosphite

The general structure of a phosphite ester showing the lone pairs on the P In organic chemistry, a phosphite ester or organophosphite usually refers to an organophosphorous compound with the formula P(OR)3. They can be considered as esters of an unobserved tautomer phosphorous acid, H3PO3, with the simplest example being trimethylphosphite, P(OCH3)3. Some phosphites can be considered esters of the dominant tautomer of phosphorous acid (HP(O)(OH)2). The simplest representative is dimethylphosphite with the formula HP(O)(OCH3)2. Both classes of phosphites are usually colorless liquids. Synthesis ;From PCl3 Phosphite esters are typically prepared by treating phosphorus trichloride with an alcohol. For alkyl alcohols the displaced chloride ion can attack the phosphite, causing dealkylation to give a dialkylphosphite and an organochlorine compound. The overall reaction is as follows: :PCl3 + 3 C2H5OH → (C2H5O)2P(O)H + 2 HCl + C2H5Cl Alternatively, when the alcoh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SNOX Process

The SNOX process is a process which removes sulfur dioxide, nitrogen oxides and particulates from flue gases. The sulfur is recovered as concentrated sulfuric acid and the nitrogen oxides are reduced to free nitrogen. The process is based on the well-known wet sulfuric acid process (WSA), a process for recovering sulfur from various process gasses in the form of commercial quality sulfuric acid (H2SO4). The SNOX process is based on catalytic reactions and does not consume water or absorbents. Neither does it produce any waste, except for the separated dust. In addition the process can handle other sulfurous waste streams. This is highly interesting in refineries, where e.g. hydrogen sulfide (H2S) gas, sour water stripper gas and Claus tail gas can be led to the SNOX plant, and thereby investment in other waste gas handling facilities can be saved. Process The SNOX process includes the following steps: *Dust removal *Catalytic reduction of NOx by adding NH3 to the gas upstream ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |