|

Chisel

A chisel is a hand tool with a characteristic Wedge, wedge-shaped cutting edge on the end of its blade. A chisel is useful for carving or cutting a hard material such as woodworking, wood, lapidary, stone, or metalworking, metal. Using a chisel involves forcing the blade into some material to cut it. The driving force may be applied by pushing by hand, or by using a mallet or hammer. In industrial use, a hydraulic ram or falling weight ('trip hammer') may be used to drive a chisel into the material. A Chisel#Gouge, gouge is a type of chisel that serves to carve small pieces from the material; particularly in woodworking, woodturning and sculpture. Woodworking Woodworking chisels range from small hand tools for tiny details, to large chisels used to remove big sections of wood, in 'roughing out' the shape of a pattern or design. Typically, in Wood carving, woodcarving, one starts with a larger tool, and gradually progresses to smaller tools to finish the detail. One of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

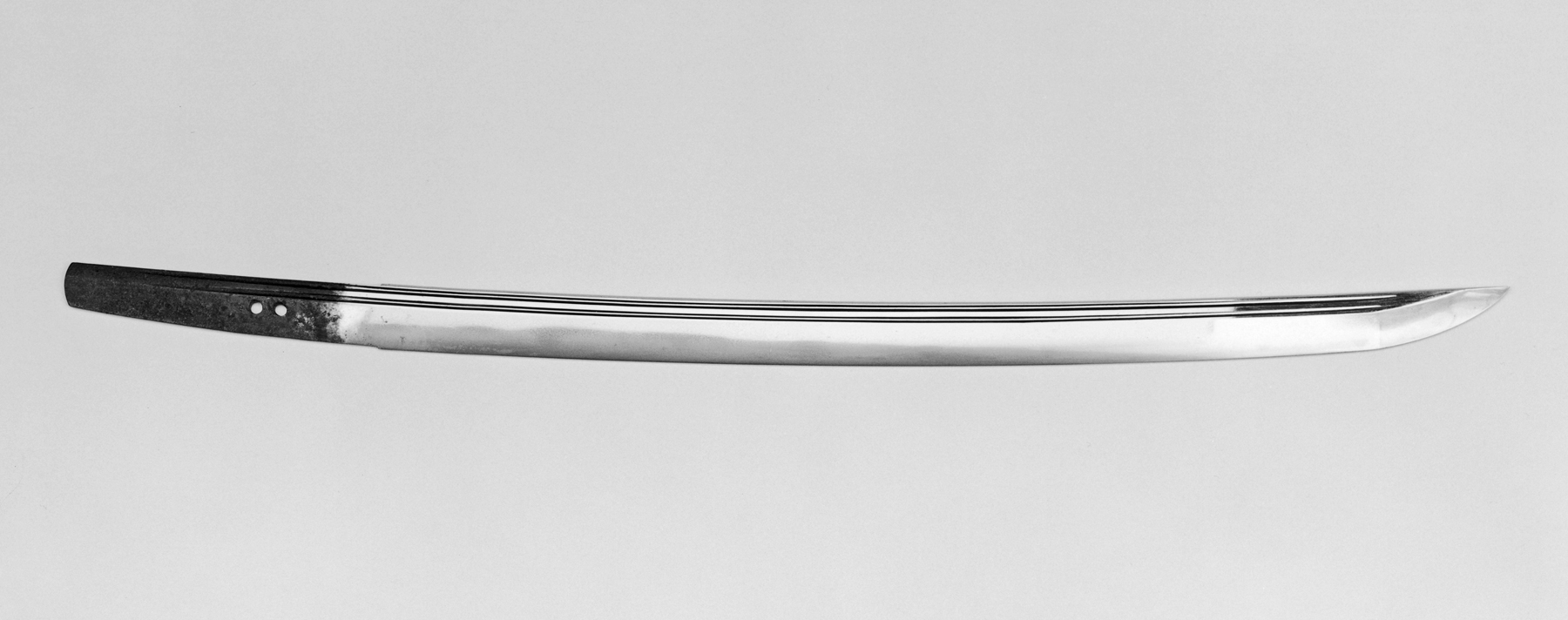

Blade

A blade is the Sharpness (cutting), sharp, cutting portion of a tool, weapon, or machine, specifically designed to puncture, chop, slice, or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are intended to cut. This includes early examples made from flaked stones like flint or obsidian, evolving through the ages into metal forms like copper, bronze, and iron, and culminating in modern versions made from steel or ceramics. Serving as one of humanity's oldest tools, blades continue to have wide-ranging applications, including in combat, cooking, and various other everyday and specialized tasks. Blades function by concentrating force at the cutting edge. Design variations, such as serrated edges found on bread knives and saws, serve to enhance this force concentration, adapting blades for specific functions and materials. Blades thus hold a significant place both historically and in contemporary society, reflecting an evolution i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Woodworking

Woodworking is the skill of making items from wood, and includes cabinetry, furniture making, wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among the earlliest finds of woodworking are shaped sticks displaying notches from Kalambo Falls in southen Africa, dating to around 476,000 years ago. The Clacton spearhead from Clacton-on-Sea, England, dating to around 400,000 years ago,Allington-Jones, L., (2015) ''Archaeological Journal'', 172 (2) 273–296 The Clacton Spear – The Last One Hundred Years the Schöningen spears, from Schöningen (Germany) dating around 300,000 years ago and the Lehringen spear from no ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nail (fastener), nails into wood, to shape metal (as with a forge), or to crush Rock (geology), rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, war hammer, warfare, and mallet percussion, percussive musicianship (as with a gong). Hammering is use of a hammer in its strike capacity, as opposed to pry bar, prying with a secondary claw or grappling with a secondary hook. Carpentry and blacksmithing hammers are generally wielded from a stationary stance against a stationary target as gripped and propelled with one arm, in a lengthy downward plane (geometry), planar arc—downward to add kinetic energy to the impact—pivoting mainly around the shoulder and elbo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Slick (tool)

A slick is a large chisel, characterized by a wide (2-4 inches, 5–10 cm), heavy blade, and a long, frequently slender, socketed handle. A long, flat metal plate fitted with an offset handle. The combined blade and handle can reach two feet (60 cm) in length. The blade of a slick is slightly curved lengthwise, and/or the handle socket is cranked upward, such that the handle and socket clear the surface of the work when the edge is touching. This distinguishes the slick from the similarly sized, short-handled millwright's chisel. Use A slick is always pushed; never struck (thus the slender handle). Using a combination of the tool's weight and bracing the handle against the shoulder or upper arm, fine paring cuts are made. Slicks are typically used by shipwrights and Timber framing, timber framers. See also * References * External linksHand Tools & Accessories [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Corner Chisel

A corner chisel is a tool for cutting sharp internal corners in wood, often used for mortise joints or hinge rebates. The hole will typically be cut by a router, or occasionally drilled, leaving rounded corners. The function of the corner chisel is therefore similar to the square mortising chisel used on a mortising machine. {{Woodworking, state=collapsed Woodworking chisels Chisels ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Mortise And Tenon

A mortise and tenon (occasionally mortice and tenon) is a Woodworking joints, joint that connects two pieces of wood or other material. Woodworking, Woodworkers around the world have used it for thousands of years to join pieces of wood, mainly when the adjoining pieces connect at right angles, though it can be used to connect two work pieces at any angle. Mortise-and tenon-joints are simple, strong, and stable, and can be used in many projects and which give an attractive look. They are either glued or friction-fitted into place. This joint is difficult to make, because of the precise measuring and tight cutting required; as such, modern woodworkers often use machinery specifically designed to cut mortises and matching tenons quickly and easily. Still, many woodworkers cut them by hand in a traditional manner. There are many variations of this type of joint, but its basic structure has two components, the ''mortise'' hole and the ''tenon'' tongue. The tenon, formed on the end o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Framing Slick

A slick is a large chisel, characterized by a wide (2-4 inches, 5–10 cm), heavy blade, and a long, frequently slender, socketed handle. A long, flat metal plate fitted with an offset handle. The combined blade and handle can reach two feet (60 cm) in length. The blade of a slick is slightly curved lengthwise, and/or the handle socket is cranked upward, such that the handle and socket clear the surface of the work when the edge is touching. This distinguishes the slick from the similarly sized, short-handled millwright's chisel. Use A slick is always pushed; never struck (thus the slender handle). Using a combination of the tool's weight and bracing the handle against the shoulder or upper arm, fine paring cuts are made. Slicks are typically used by shipwright Shipbuilding is the construction of ships and other floating vessels. In modern times, it normally takes place in a specialized facility known as a shipyard. Shipbuilders, also called shipwrights, follow a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Woodturning

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a mechanism that can generate a variety of forms. The operator is known as a ''turner'', and the skills needed to use the tools were traditionally known as ''turnery''. In pre-industrial England, these skills were sufficiently difficult to be known as "the mysteries of the turners' guild." The skills to use the tools by hand, without a fixed point of contact with the wood, distinguish woodturning and the wood lathe from the machinist's lathe, or metal-working lathe. Items made on the lathe include tool handles, candlesticks, egg cups, knobs, lamps, rolling pins, cylindrical boxes, Christmas ornaments, bodkins, knitting needles, needle cases, thimbles, pens, chessmen, spinning tops; legs, spindles, and pegs for furniture; balusters and newel posts for architecture; baseball bats, hollow forms such a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Oxford University Press

Oxford University Press (OUP) is the publishing house of the University of Oxford. It is the largest university press in the world. Its first book was printed in Oxford in 1478, with the Press officially granted the legal right to print books by decree in 1586. It is the second-oldest university press after Cambridge University Press, which was founded in 1534. It is a department of the University of Oxford. It is governed by a group of 15 academics, the Delegates of the Press, appointed by the Vice Chancellor, vice-chancellor of the University of Oxford. The Delegates of the Press are led by the Secretary to the Delegates, who serves as OUP's chief executive and as its major representative on other university bodies. Oxford University Press has had a similar governance structure since the 17th century. The press is located on Walton Street, Oxford, Walton Street, Oxford, opposite Somerville College, Oxford, Somerville College, in the inner suburb of Jericho, Oxford, Jericho. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |