|

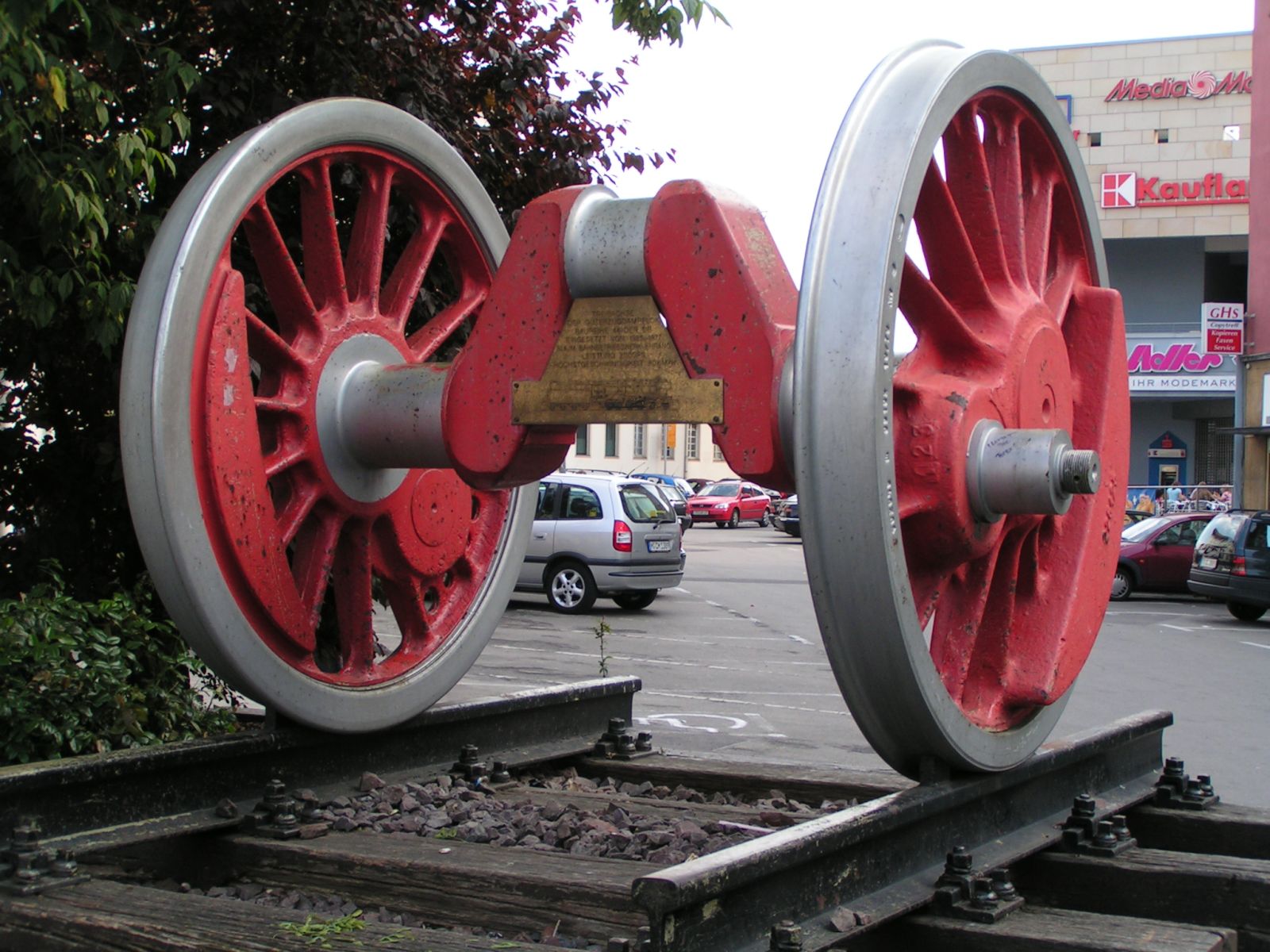

Crankshafts

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft is located within the engine block and held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crossplane

The crossplane or cross-plane is a crankshaft design for piston engines with a 90° angle (phase in crank rotation) between the crank throws. The crossplane crankshaft is the most popular configuration used in V8 road cars. Aside from the V8 already mentioned, other examples of configurations using such 90° piston phases include straight-2, straight-4, V2, and V4 engines. Crossplane crankshafts could feasibly be used with a great many other cylinder configurations, but the advantages and disadvantages described below may not apply to any or all of them and must be considered on a case-by-case basis. Triumph T-plane Triumph T-plane is a crankshaft design for piston engines with a 270° angle (phase in crank rotation), and T-plane are T shaped crankshaft. The T-plane can be used for inline-3, inline-6 and V6 engines. T-plane use on Triumph Tiger 900 (2020) motorcycle with firing order 180-270-270. T-plane are uneven firing order which similar to Crossplane, but differen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankpin

A crankpin or crank pin, also known as a rod bearing journal, is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder. It has a cylindrical surface, to allow the crankpin to rotate relative to the "big end" of the connecting rod. The most common configuration is for a crankpin to serve one cylinder. However, many V engines have each crankpin shared by each pair of cylinders. Design The crankpin connects to the larger end of the connecting rod for each cylinder. This end of the connecting rod is called the "big end", as opposed to the "small end" or "little end" (which connects to the wrist/gudgeon pin in the piston). The bearing which allows the crankpin to rotate around its shaft is called the "rod bearing". In automotive engines, the most common type of rod bearing is the plain bearing, however bushings or roller bearings are also used in some engines. Configurations In a single-cylinder engine, straight engine or fla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Main Bearing

A main bearing is a bearing in a piston engine which holds the crankshaft in place and allows it to rotate within the engine block. The number of main bearings per engine varies between engines, often in accordance with the forces produced by the operation of the engine. Main bearings are usually plain bearings or journal bearings, held in place by the engine block and bearing caps. Number of main bearings The number of main bearings is primarily determined by the overall load factor and maximum engine speed. Increasing the number of bearings in an engine will generally increase the size and cost of the engine, but also reduces bending stress and deflection caused by the distance from the crank pins to the nearest bearings. Most engines have at least two main bearings— one at each end of the crankshaft. Additional bearings may be located along the crankshaft, sometimes as many as one bearing per crank pin, as used on many modern diesel engines and petrol engines des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

LS Based GM Small-block Engine

The General Motors LS-based small-block engines are a family of V8 and offshoot V6 engines designed and manufactured by the American automotive company General Motors. Introduced in 1997, the family is a continuation of the earlier first- and second-generation Chevrolet small-block engine, of which over 100 million have been produced altogether and is also considered one of the most popular V8 engines ever. The LS family spans the third, fourth, and fifth generations of the small-block engines, with a sixth generation expected to enter production soon. Various small-block V8s were and still are available as crate engines. The "LS" nomenclature originally came from the Regular Production Option (RPO) code LS1, assigned to the first engine in the Gen III engine series. The LS nickname has since been used to refer generally to all Gen III and IV engines, but that practice can be misleading, since not all engine RPO codes in those generations begin with LS. Likewise, although ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ford Modular Engine

The Ford Modular engine is an overhead camshaft (OHC) V8 and V10 gasoline-powered small block engine family introduced by Ford Motor Company in 1990 for the 1991 model year. The term “modular” applied to the setup of tooling and casting stations in the Windsor and Romeo engine manufacturing plants, not the engine itself. The Modular engine family started with the 4.6 L in 1990 for the 1991 model year. The Modular engines are used in various Ford, Lincoln, and Mercury vehicles. Modular engines used in Ford trucks were marketed under the Triton name from 1997–2010 while the InTech name was used for a time at Lincoln and Mercury for vehicles equipped with DOHC versions of the engines. The engines were first produced at the Ford Romeo Engine Plant, then additional capacity was added at the Windsor Engine Plant in Windsor, Ontario. Origins In the early 1980s, then-Ford Motor Company chief operating officer Donald Petersen challenged Ford's vice-president of design, J ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Firing Order

The firing order of an internal combustion engine is the sequence of ignition for the cylinders. In a spark ignition (e.g. gasoline/petrol) engine, the firing order corresponds to the order in which the spark plugs are operated. In a diesel engine, the firing order corresponds to the order in which fuel is injected into each cylinder. Four-stroke engines must also time the valve openings relative to the firing order, as the valves do not open and close on every stroke. Firing order affects the vibration, sound and evenness of power output from the engine and heavily influences crankshaft design. Cylinder numbering Numbering systems for car engines The numbering system for cylinders is generally based on the cylinder numbers increasing from the front to the rear of an engine (See engine orientation below). However, there are differences between manufacturers in how this is applied; some commonly used systems are as listed below. Straight engine In a straight engine the cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Bore

In a piston engine, the bore (or cylinder bore) is the diameter of each cylinder. Engine displacement is calculated based on bore, stroke length and the number of cylinders: displacement = The stroke ratio, determined by dividing the bore by the stroke, traditionally indicated whether an engine was designed for power at high engine speeds ( rpm) or torque at lower engine speeds. The term "bore" can also be applied to the bore of a locomotive cylinder or steam engine pistons. In steam locomotives The term bore also applies to the cylinder of a steam locomotive or steam engine. Bore pitch Bore pitch is the distance between the centerline of a cylinder bore to the centerline of the next cylinder bore adjacent to it in an internal combustion engine. It's also referred to as the "mean cylinder width", "bore spacing", "bore center distance" and "cylinder spacing". The bore pitch is always larger than the inside diameter of the cylinder (the bore and piston diameter) sinc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stroke (engine)

In the context of an internal combustion engine, the term stroke has the following related meanings: * A phase of the engine's cycle (e.g. compression stroke, exhaust stroke), during which the piston travels from top to bottom or vice versa. * The type of power cycle used by a piston engine (e.g. two-stroke engine, four-stroke engine). * "Stroke length", the distance travelled by the piston during each cycle. The stroke length, along with bore diameter, determines the engine's displacement. Phases in the power cycle Commonly used engine phases or strokes (i.e. those used in a four-stroke engine) are described below. Other types of engines can have very different phases. Induction-intake stroke The induction stroke is the first phase in a four-stroke (e.g. Otto cycle or Diesel cycle) engine. It involves the downward movement of the piston, creating a partial vacuum that draws an air-fuel mixture (or air alone, in the case of a direct injection engine) into the combustion ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression Ratio

The compression ratio is the ratio between the maximum and minimum volume during the compression stage of the power cycle in a piston or Wankel engine. A fundamental specification for such engines, it can be measured in two different ways. The simpler way is the static compression ratio: in a reciprocating engine, this is the ratio of the volume of the cylinder when the piston is at the bottom of its stroke to that volume when the piston is at the top of its stroke. The dynamic compression ratio is a more advanced calculation which also takes into account gases entering and exiting the cylinder during the compression phase. Effect and typical ratios A high compression ratio is desirable because it allows an engine to extract more mechanical energy from a given mass of air–fuel mixture due to its higher thermal efficiency. This occurs because internal combustion engines are heat engines, and higher compression ratios permit the same combustion temperature to be reached wit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-eight Engine

The straight-eight engine or inline-eight engine (often abbreviated as I8) is an eight-cylinder internal combustion engine with all eight cylinders mounted in a straight line along the crankcase. The type has been produced in side-valve, IOE, overhead-valve, sleeve-valve, and overhead-cam configurations. A straight-eight can be timed for inherent primary and secondary balance, with no unbalanced primary or secondary forces or moments. However, crankshaft torsional vibration, present to some degree in all engines, is sufficient to require the use of a harmonic damper at the accessory end of the crankshaft. Without such damping, fatigue cracking near the rear main bearing journal may occur, leading to engine failure. Although an inline six-cylinder engine can also be timed for inherent primary and secondary balance, a straight-eight develops more power strokes per revolution and, as a result, will run more smoothly under load than an inline six. Also, due to the eve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after the German engineer Rudolf Diesel, is an internal combustion engine in which Combustion, ignition of diesel fuel is caused by the elevated temperature of the air in the cylinder due to Mechanics, mechanical Compression (physics), compression; thus, the diesel engine is called a compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Introduction Diesel engines work by compressing only air, or air combined with residual combustion gases from the exhaust (known as exhaust gas recirculation, "EGR"). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases air temperature inside the Cylinder (engine), cylinder so that atomised diesel fuel injected into the combustion chamber ignites. The torque a dies ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torsion (mechanics)

In the field of solid mechanics, torsion is the twisting of an object due to an applied torque. Torsion could be defined as strain or angular deformation, and is measured by the angle a chosen section is rotated from its equilibrium position. The resulting stress (torsional shear stress) is expressed in either the Pascal (unit), pascal (Pa), an SI unit for newtons per square metre, or in pounds per square inch (psi) while torque is expressed in newton metres (N·m) or foot-pound force (ft·lbf). In sections perpendicular to the torque axis, the resultant shear stress in this section is perpendicular to the radius. In non-circular cross-sections, twisting is accompanied by a distortion called warping, in which transverse sections do not remain plane. For shafts of uniform cross-section unrestrained against warping, the torsion-related physical properties are expressed as: : T = \frac \tau= \frac G \varphi where: * ''T'' is the applied torque or moment of torsion in Nm. * \tau (t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |