|

Compression Moulding

Compression molding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured; this process is known as compression molding method and in case of rubber it is also known as 'Vulcanisation'. The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms. Compression molding is a high-volume, high-pressure method suitable for molding complex, high-strength fiberglass reinforcements. Advanced composite thermoplastics can also be compression molded with unidirectional tapes, woven fabrics, randomly oriented fiber mat or chopped strand. The advantage of compression molding is its ability to mold large, fairly intricate parts. Also, it is one of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Compression Molding

Compression molding is a method of molding (process), molding in which the molding material, generally preheated, is first placed in an open, heated Molding (process), mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured; this process is known as compression molding method and in case of rubber it is also known as 'Vulcanisation'. The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms. Compression molding is a high-volume, high-pressure method suitable for molding complex, high-strength fiberglass reinforcements. Advanced composite thermoplastics can also be compression molded with unidirectional tapes, woven fabrics, randomly oriented fiber mat or chopped strand. The advantage of compression molding is its ability to mold large, fairly i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Injection Molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Extrusion

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive stress, compressive and shear stress, shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing (manufacturing), Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal Bar stock, bars and tube (fluid conveyance), tubes are also often drawn. Extrusion may be continuous (theoretically producin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Shearing (manufacturing)

Shearing, also known as die cutting, is a process that cuts stock without the formation of chips or the use of burning or melting. Strictly speaking, if the cutting blades are straight the process is called shearing; if the cutting blades are curved then they are shearing-type operations.Degarmo, p. 424. The most commonly sheared materials are in the form of sheet metal or plates. However, rods can also be sheared. Shearing-type operations include Blanking (metalworking), blanking, Piercing (metalworking), piercing, roll slitting, and trimming. It is used for metal, fabric, paper and plastics. Principle A punch (or moving blade) is used to push a workpiece against the die (or fixed blade), which is fixed. Usually, the clearance between the two is 5 to 40% of the thickness of the material, but dependent on the material. Clearance is defined as the separation between the blades, measured at the point where the cutting action takes place and perpendicular to the direction of blade mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

PEEK

Polyether ether ketone (PEEK) is a beige coloured organic thermoplastic polymer in the polyaryletherketone (PAEK) family, used in engineering applications. It was invented in November 1978 and brought to market in the early 1980s by part of Imperial Chemical Industries (ICI), the PEEK division was acquired through a management buyout, giving rise to Victrex PLC. Synthesis PEEK polymers are obtained by step-growth polymerization by the dialkylation of bis phenolate salts. Typical is the reaction of 4,4'-difluorobenzophenone with the disodium salt of hydroquinone, which is generated in situ by deprotonation with sodium carbonate. The reaction is conducted around 300 °C in polar aprotic solvents - such as diphenyl sulfone. Properties PEEK is a semicrystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures. The processing conditions used to mould PEEK can influence the crystallinity and hence the mec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Poly(p-phenylene Sulfide)

Polyphenylene sulfide (PPS) is an organic polymer consisting of aromatic rings linked by thioether, sulfides. Synthetic fiber and textiles derived from this polymer resist chemical and thermal attack. PPS is used in air filter, filter fabric for coal boilers, papermaking felts, electrical insulation, film capacitor#Polyphenylene sulfide (PPS) film capacitors, film capacitors, specialty synthetic membrane, membranes, gaskets, and seal (mechanical), packings. PPS is the precursor to a conductive polymer of the semi-flexible rod polymer family. The PPS, which is otherwise insulating, can be converted to the semiconductor, semiconducting form by oxidation or use of dopants.David Parker, Jan Bussink, Hendrik T. van de Grampel, Gary W. Wheatley, Ernst-Ulrich Dorf, Edgar Ostlinning, Klaus Reinking, "Polymers, High-Temperature" in Ullmann's Encyclopedia of Industrial Chemistry 2002, Wiley-VCH: Weinheim. Polyphenylene sulfide is an engineering plastic, commonly used today as a high-perf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Vespel

Vespel is the trademark of a range of durable high-performance polyimide-based plastics made by DuPont. Characteristics and applications Vespel is mostly used in aerospace, semiconductor, and transportation technology. It combines heat resistance, lubricity, dimensional stability, chemical resistance, and creep resistance, and can be used in hostile and extreme environmental conditions. Unlike most plastics, it does not produce significant outgassing even at high temperatures, which makes it useful for lightweight heat shields and crucible support. It also performs well in vacuum applications, down to extremely low cryogenic temperatures. However, Vespel tends to absorb a small amount of water, resulting in longer pump time while placed in a vacuum. Although there are polymers surpassing polyimide in each of these properties, the combination of them is the main advantage of Vespel. Thermophysical properties Vespel is commonly used as a thermal conductivity reference mat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

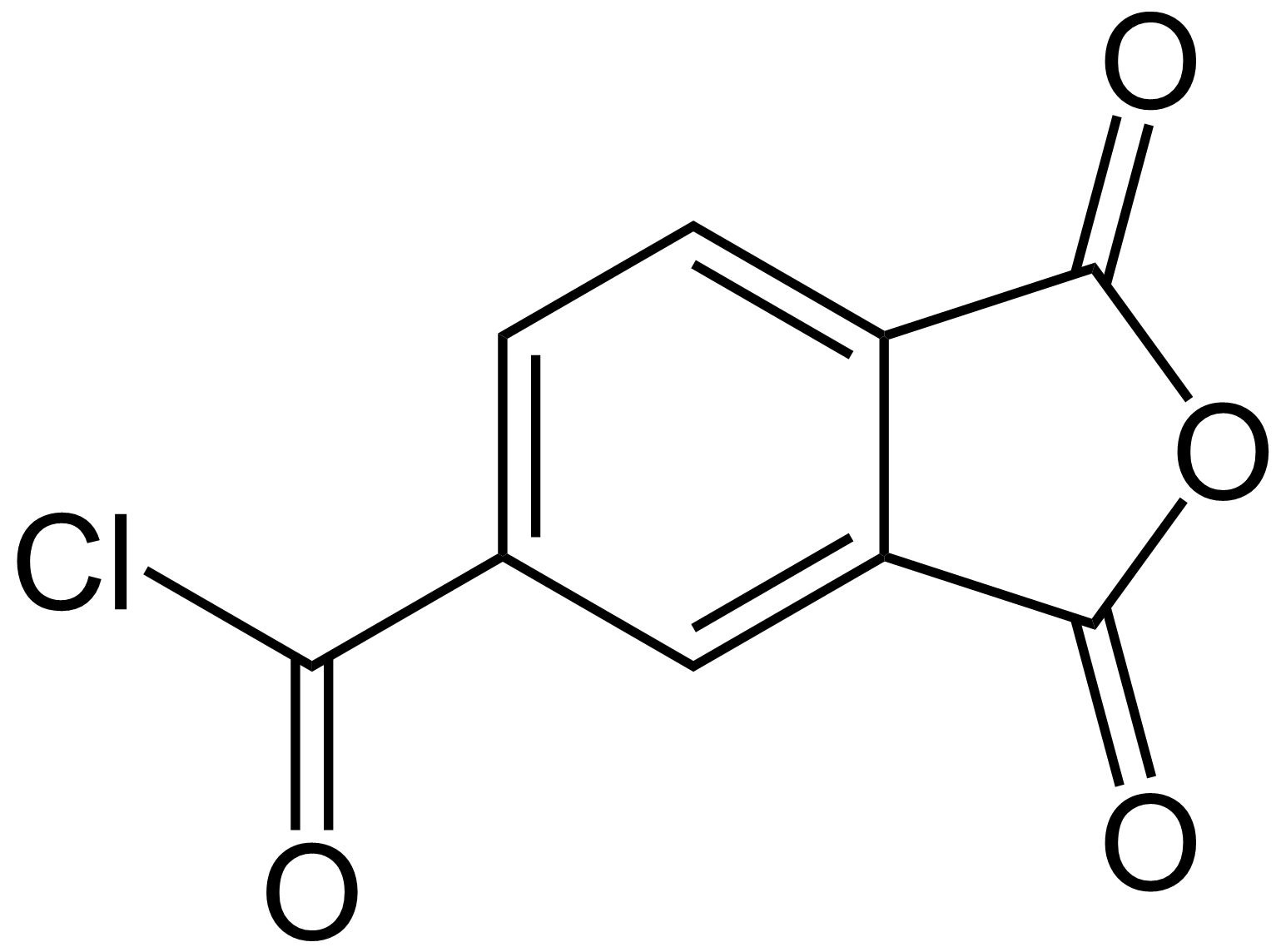

Torlon

Polyamide-imides are either thermosetting or thermoplastic, amorphous polymers that have exceptional mechanical, thermal and chemical resistant properties. Polyamide-imides are used extensively as wire coatings in making magnet wire. They are prepared from isocyanates and TMA (trimellic acid-anhydride) in ''N''-methyl-2-pyrrolidone (NMP). A prominent distributor of polyamide-imides is Solvay Specialty Polymers, which uses the trademark Torlon. Polyamide-imides display a combination of properties from both polyamides and polyimides, such as high strength, melt processibility, exceptional high heat capability, and broad chemical resistance. Polyamide-imide polymers can be processed into a wide variety of forms, from injection or compression molded parts and ingots, to coatings, films, fibers and adhesives. Generally these articles reach their maximum properties with a subsequent thermal cure process. Other high-performance polymers in this same realm are polyetheretherketones and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Knit Line

In manufacturing, the Weld line or Knit line or Meld line is the line where two flow fronts meet when there is the inability of two or more flow fronts to "knit" together, or " weld", during the molding process. These lines usually occur around holes or obstructions and cause locally weak areas in the molded part. Knit lines are considered molding defects, and occur when the mold or/and material temperatures are set too low: thus the materials will be cold when they meet, so that they do not bond perfectly. This can cause a weak area in the part which can cause breakage when the part is under stress. Weld lines therefore occur during machine start-up, when equilibrium conditions have not been met. Mouldings made in this setting-up period must be rejected. There are many Computer Aided Engineering tools that are available that can predict where these areas could occur, but a skilled designer will be able to predict where such defects can be found by examining the tool or product. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Molding Flash

Flash, also known as flashing, is excess material attached to a molded, forged, or cast Cast may refer to: Music * Cast (band), an English alternative rock band * Cast (Mexican band), a progressive Mexican rock band * The Cast, a Scottish musical duo: Mairi Campbell and Dave Francis * ''Cast'', a 2012 album by Trespassers William ... product, which must usually be removed. This is typically caused by leakage of the material between the two surfaces of a mold (beginning along the parting line) or between the base material and the mold in the case of overmolding. Details Molding flash is seen when the optimized parameter on cull height is not calibrated. Proper design of mold parting surfaces can reduce or eliminate flash. Molding flash can be caused from old or worn mold cavities that no longer fit tightly together. Other times, the complexity of the part requires so many mating pieces with such precise geometries that it is almost impossible to create a perfect fit on ev ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Transfer Molding

Transfer molding ( BrE: transfer moulding) is a manufacturing process in which casting material is forced into a mold. Transfer molding is different from compression molding in that the mold is enclosed rather than open to the fill plunger resulting in higher dimensional tolerances and less environmental impact. Compared to injection molding, transfer molding uses higher pressures to uniformly fill the mold cavity. This allows thicker reinforcing fiber matrices to be more completely saturated by resin. Furthermore, unlike injection molding, the transfer mold casting material may start the process as a solid. This can reduce equipment costs and time dependency. The transfer process may have a slower fill rate than an equivalent injection molding process. Process The mold interior surfaces may be gel-coated. If desired, the mold is first pre-loaded with a reinforcing fiber matrix or preform. Fiber content of a transfer molded composite can be as high as 60% by volume. The fil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |