|

Clad Coinage

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure. The United States Mint uses cladding to manufacture coins from different metals. This allows a cheaper metal to be used as a filler. For example, dimes and quarters struck since 1965 have cores made from pure copper, with a clad layer consisting of 75% copper and 25% nickel added during production. Half dollars struck from 1965 to 1969 for circulation and in 1970 for collectors also incorporated cladding, albeit in the case of those coins, the core was a mixture of 20.9% silver and 79.1% copper, and its clad layer was 80% silver and 20% copper. Half dollars struck since 1971 are produced identically to the dimes and quarters. Laser cladding is an additive manufacturing approach for metal coatings or preci ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated with having electrons available at the Fermi level, as against nonmetallic materials which do not. Metals are typically ductile (can be drawn into a wire) and malleable (can be shaped via hammering or pressing). A metal may be a chemical element such as iron; an alloy such as stainless steel; or a molecular compound such as polythiazyl, polymeric sulfur nitride. The general science of metals is called metallurgy, a subtopic of materials science; aspects of the electronic and thermal properties are also within the scope of condensed matter physics and solid-state chemistry, it is a multidisciplinary topic. In colloquial use materials such as steel alloys are referred to as metals, while others such as polymers, wood or ceramics are nonmetallic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

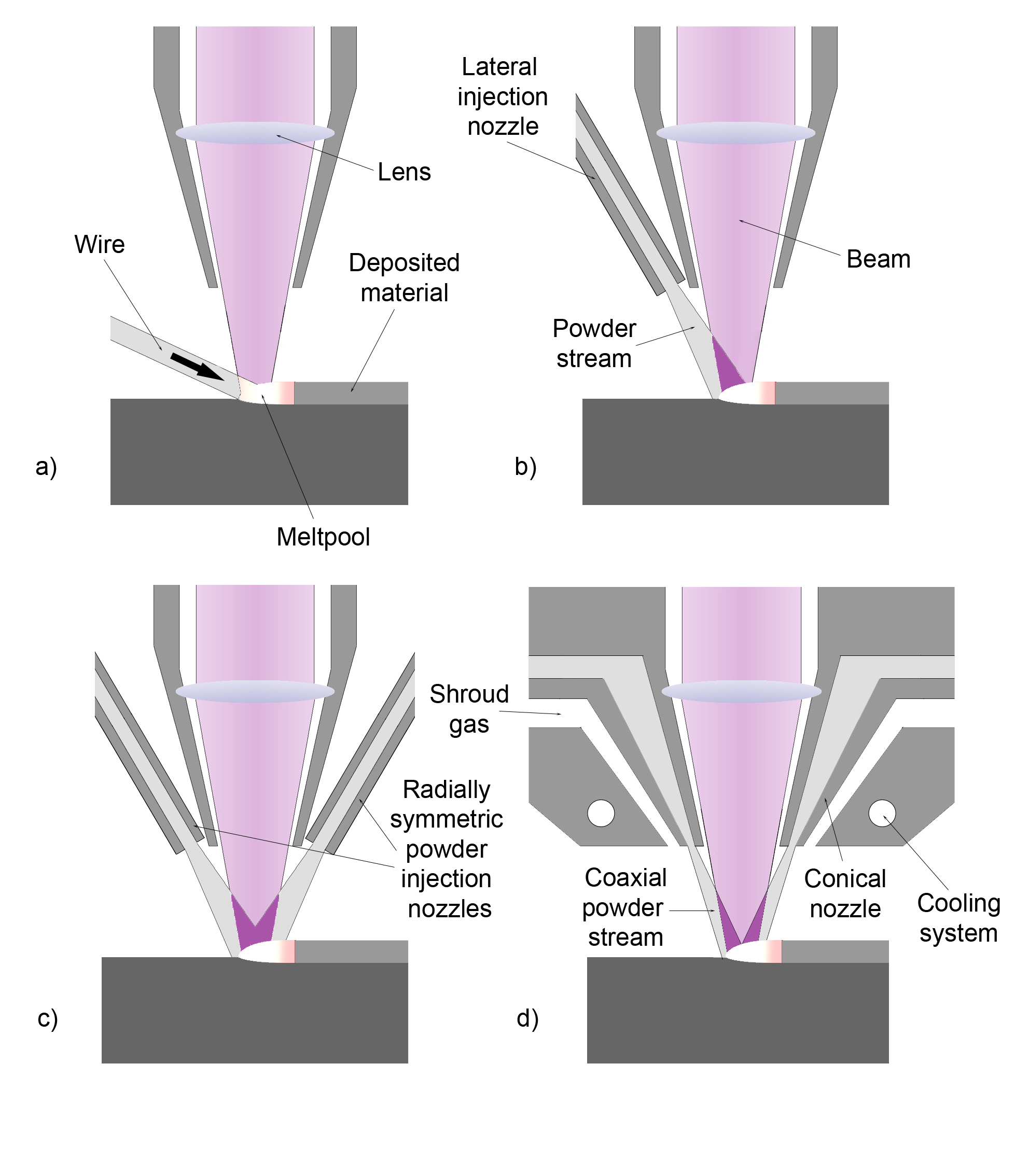

Laser Cladding System Setup

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of radiation. The first laser was built in 1960 by Theodore Maiman at Hughes Research Laboratories, based on theoretical work by Charles H. Townes and Arthur Leonard Schawlow and the optical amplifier patented by Gordon Gould. A laser differs from other sources of light in that it emits light that is ''coherent''. Spatial coherence allows a laser to be focused to a tight spot, enabling uses such as optical communication, laser cutting, and lithography. It also allows a laser beam to stay narrow over great distances ( collimation), used in laser pointers, lidar, and free-space optical communication. Lasers can also have high temporal coherence, which permits them to emit light with a very narrow frequency spectrum. Temporal coherence can al ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Affected Zone

In fusion welding, the heat-affected zone (HAZ) is the area of base material, either a metal or a thermoplastic, which is not melted but has had its microstructure and properties altered by welding or heat intensive cutting operations. The heat from the welding process and subsequent re-cooling causes this change from the weld interface to the termination of the sensitizing temperature in the base metal. The extent and magnitude of property change depends primarily on the base material, the weld filler metal, and the amount and concentration of heat input by the welding process. The thermal diffusivity of the base material plays a large role—if the diffusivity is high, the material cooling rate is high and the HAZ is relatively small. Alternatively, a low diffusivity leads to slower cooling and a larger HAZ. The amount of heat input during the welding process also plays an important role as well, as processes like oxyfuel welding use high heat input and increase the size ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Welding Processes

This is a list of welding processes, separated into their respective categories. The associated ''N reference numbers'' (second column) are specified in ISO 4063 (in the European Union published as ''EN ISO 4063''). Numbers in parentheses are obsolete and were removed from the current (1998) version of ISO 4063. The AWS reference codes of the American Welding Society are commonly used in North America."Welding Inspection Handbook", 3rd edition, American Welding Society, , Miami, FL, pp. 10-11 (2000) Arc welding ''Overview article: arc welding'' Oxyfuel gas welding ''Overview article: Oxy-fuel welding and cutting'' Resistance welding ''Overview article: electric resistance welding'' Solid-state welding Other types of welding Notes and references *Cary, Howard B. and Scott C. Helzer (2005). Modern Welding Technology. Upper Saddle River, New Jersey: Pearson Education. . *Lincoln Electric (1994). The Procedure Handbook of Arc Welding. Cleveland: Lincoln Electric. . ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Near Net Shape

Near-net-shape is an industrial manufacturing technique. As the name implies, the initial production of the item is very close to the final, or ''net'', shape. This reduces the need for surface finishing. By minimizing the use of finishing methods like machining or grinding, near-net-shape production eliminates more than two-thirds of the production costs in some industries. Processes The following are various near-net-shape processes categorized by material. Ceramics * Gelcasting * Ceramic injection molding * Spray forming *Structural ceramic production Composites * Lanxide process Plastics *Injection moulding *Rapid prototyping Metals *Casting ** Permanent mold casting *Powder metallurgy * Linear friction welding * Friction welding * Metal injection molding *Rapid prototyping * Spray forming * Superplastic forming *Cold forming * Semi-solid metal casting *Photochemical machining Photochemical machining (PCM), also known as photochemical milling or photo etching, is a che ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Functionally Graded Material

In materials science Functionally Graded Materials (FGMs) may be characterized by the variation in composition and structure gradually over volume, resulting in corresponding changes in the properties of the material. The materials can be designed for specific function and applications. Various approaches based on the bulk (particulate processing), preform processing, layer processing and melt processing are used to fabricate the functionally graded materials. History The concept of FGM was first considered in Japan in 1984 during a space plane project, where a combination of materials used would serve the purpose of a thermal barrier capable of withstanding a surface temperature of 2000 K and a temperature gradient of 1000 K across a 10 mm section. In recent years this concept has become more popular in Europe, particularly in Germany. A transregional collaborative research center (SFB Transregio) is funded since 2006 in order to exploit the potential of grading monomateria ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Cladding Nozzle Configurations

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of radiation. The first laser was built in 1960 by Theodore Maiman at Hughes Research Laboratories, based on theoretical work by Charles H. Townes and Arthur Leonard Schawlow and the optical amplifier patented by Gordon Gould. A laser differs from other sources of light in that it emits light that is ''coherent''. Spatial coherence allows a laser to be focused to a tight spot, enabling uses such as optical communication, laser cutting, and lithography. It also allows a laser beam to stay narrow over great distances (collimation), used in laser pointers, lidar, and free-space optical communication. Lasers can also have high temporal coherence, which permits them to emit light with a very narrow frequency spectrum. Temporal coherence can also ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, Industrial management, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tribological

Tribology is the science and engineering of understanding friction, lubrication and wear phenomena for interacting surfaces in relative motion. It is highly interdisciplinary, drawing on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. The fundamental objects of study in tribology are tribosystems, which are physical systems of contacting surfaces. Subfields of tribology include biotribology, nanotribology and space tribology. It is also related to other areas such as the coupling of corrosion and tribology in tribocorrosion and the contact mechanics of how surfaces in contact deform. Approximately 20% of the total energy expenditure of the world is due to the impact of friction and wear in the transportation, manufacturing, power generation, and residential sectors. Etymology The word ''tribology'' derives from the Greek root τριβ- of the verb , '' tribo'', "I rub" in classic Greek, and the suffix ''-logy'' from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

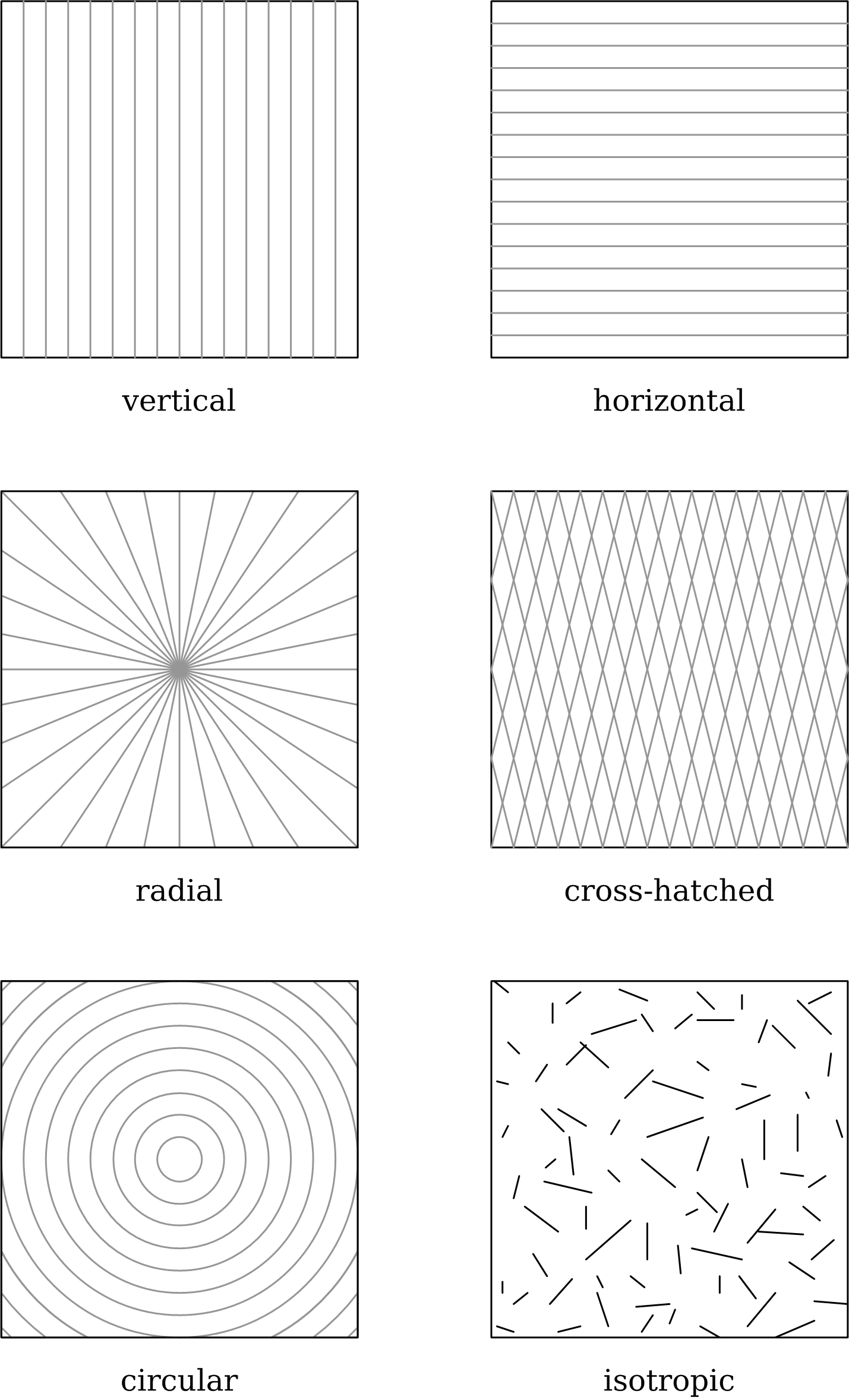

Surface Topography

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane). Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic or anisotropic. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting), polis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lubrication

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology. Lubrication mechanisms such as fluid-lubricated systems are designed so that the applied load is partially or completely carried by hydrodynamic or hydrostatic pressure, which reduces solid body interactions (and consequently friction and wear). Depending on the degree of surface separation, different lubrication regimes can be distinguished. Adequate lubrication allows smooth, continuous operation of machine elements, reduces the rate of wear, and prevents excessive stresses or seizures at bearings. By repelling water and other substances, it also reduces corrosion. When lubrication breaks down, components can rub destructively against each other, causing heat, local welding, destructive damage and failure. Lubrication mechanisms Fluid-lubricated systems As the load incre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Matrix Composite

In materials science, a metal matrix composite (MMC) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel. The secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel). They are typically classified according to the type of reinforcement: short discontinuous fibers (whiskers), continuous fibers, or particulates. There is some overlap between MMCs and cermets, with the latter typically consisting of less than 20% metal by volume. When at least three materials are present, it is called a hybrid composite. MMCs can have much higher strength-to-weight ratios, stiffness, and ductility than traditional materials, so they are often used in demanding applications. MMCs typically have lower thermal and electrical conductivity and poor resistance to radiation, limiting their use in the very harshest environments. Composition MMCs are made by dispersing a reinforcing mater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |