|

Shaft (mechanical Engineering)

A shaft is a rotating machine element, usually circular in cross section, which is used to transmit power from one part to another, or from a machine which produces power to a machine which absorbs power. Types They are mainly classified into two types. * Transmission shafts are used to transmit power between the source and the machine absorbing power; e.g. counter shafts and line shafts. * Machine shafts are the integral part of the machine itself; e.g. crankshaft. *Axle shaft. *Spindle shaft. Materials The material used for ordinary shafts is mild steel. When high strength is required, an alloy steel such as nickel, nickel-chromium or chromium-vanadium steel is used. Shafts are generally formed by hot rolling and finished to size by cold drawing or turning and grinding. Standard sizes Source:Mahadevan K and Reddy K.Balaveera, (2015), 'Design data hand book', CBS publishers and Distributors (P) ltd., New-Delhi, Machine shafts * Up to 25 mm steps of 0.5 mm Transmission sh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotating

Rotation, or spin, is the circular movement of an object around a '' central axis''. A two-dimensional rotating object has only one possible central axis and can rotate in either a clockwise or counterclockwise direction. A three-dimensional object has an infinite number of possible central axes and rotational directions. If the rotation axis passes internally through the body's own center of mass, then the body is said to be ''autorotating'' or ''spinning'', and the surface intersection of the axis can be called a ''pole''. A rotation around a completely external axis, e.g. the planet Earth around the Sun, is called ''revolving'' or ''orbiting'', typically when it is produced by gravity, and the ends of the rotation axis can be called the '' orbital poles''. Mathematics Mathematically, a rotation is a rigid body movement which, unlike a translation, keeps a point fixed. This definition applies to rotations within both two and three dimensions (in a plane and in space, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Standard Length

Fish measurement is the measuring of individual fish and various parts of their anatomies. These data are used in many areas of ichthyology, including taxonomy and fisheries biology. Overall length * Standard length (SL) is the length of a fish measured from the tip of the snout to the posterior end of the last vertebra or to the posterior end of the midlateral portion of the hypural plate. Simply put, this measurement excludes the length of the caudal (tail) fin. * Total length (TL) is the length of a fish measured from the tip of the snout to the tip of the longer lobe of the caudal fin, usually measured with the lobes compressed along the midline. It is a straight-line measure, not measured over the curve of the body. Standard length measurements are used with Teleostei (most bony fish), while total length measurements are used with Myxini (hagfish), Petromyzontiformes (lampreys), and (usually) Elasmobranchii (sharks and rays), as well as some other fishes. Total length meas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kinematics

Kinematics is a subfield of physics, developed in classical mechanics, that describes the motion of points, bodies (objects), and systems of bodies (groups of objects) without considering the forces that cause them to move. Kinematics, as a field of study, is often referred to as the "geometry of motion" and is occasionally seen as a branch of mathematics. A kinematics problem begins by describing the geometry of the system and declaring the initial conditions of any known values of position, velocity and/or acceleration of points within the system. Then, using arguments from geometry, the position, velocity and acceleration of any unknown parts of the system can be determined. The study of how forces act on bodies falls within kinetics, not kinematics. For further details, see analytical dynamics. Kinematics is used in astrophysics to describe the motion of celestial bodies and collections of such bodies. In mechanical engineering, robotics, and biomechanics kinematics is us ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the engineering branches. Mechanical engineering requires an understanding of core areas including mechanics, dynamics, thermodynamics, materials science, structural analysis, and electricity. In addition to these core principles, mechanical engineers use tools such as computer-aided design (CAD), computer-aided manufacturing (CAM), and product lifecycle management to design and analyze manufacturing plants, industrial equipment and machinery, heating and cooling systems, transport systems, aircraft, watercraft, robotics, medical devices, weapons, and others. Mechanical engineering emerged as a field during the Industrial Revolution in Europe in the 18th ce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machines

A machine is a physical system using power to apply forces and control movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to natural biological macromolecules, such as molecular machines. Machines can be driven by animals and people, by natural forces such as wind and water, and by chemical, thermal, or electrical power, and include a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement. They can also include computers and sensors that monitor performance and plan movement, often called mechanical systems. Renaissance natural philosophers identified six simple machines which were the elementary devices that put a load into motion, and calculated the ratio of output force to input force, known today as mechanical advantage. Modern machines are complex systems that consist of structural elements, mechanisms and control component ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

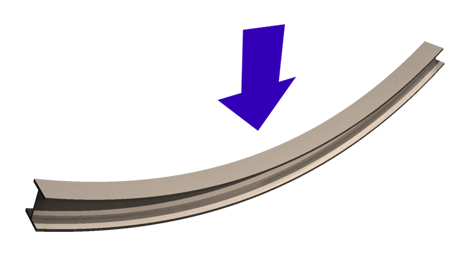

Bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a beam. For example, a closet rod sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A large diameter, but thin-walled, short tube supported at its ends an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torsional

In the field of solid mechanics, torsion is the twisting of an object due to an applied torque. Torsion is expressed in either the pascal (Pa), an SI unit for newtons per square metre, or in pounds per square inch (psi) while torque is expressed in newton metres (N·m) or foot-pound force (ft·lbf). In sections perpendicular to the torque axis, the resultant shear stress in this section is perpendicular to the radius. In non-circular cross-sections, twisting is accompanied by a distortion called warping, in which transverse sections do not remain plane. For shafts of uniform cross-section unrestrained against warping, the torsion is: : T = \frac \tau= \frac G \varphi where: * ''T'' is the applied torque or moment of torsion in Nm. * \tau (tau) is the maximum shear stress at the outer surface * ''J''T is the torsion constant for the section. For circular rods, and tubes with constant wall thickness, it is equal to the polar moment of inertia of the section, but for other shapes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulleys

A pulley is a wheel on an axle or shaft that is designed to support movement and change of direction of a taut cable or belt, or transfer of power between the shaft and cable or belt. In the case of a pulley supported by a frame or shell that does not transfer power to a shaft, but is used to guide the cable or exert a force, the supporting shell is called a block, and the pulley may be called a sheave. A pulley may have a groove or grooves between flanges around its circumference to locate the cable or belt. The drive element of a pulley system can be a rope, cable, belt, or chain. The earliest evidence of pulleys dates back to Ancient Egypt in the Twelfth Dynasty (1991-1802 BCE) and Mesopotamia in the early 2nd millennium BCE. In Roman Egypt, Hero of Alexandria (c. 10-70 CE) identified the pulley as one of six simple machines used to lift weights. Pulleys are assembled to form a block and tackle in order to provide mechanical advantage to apply large forces. Pulleys are a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gears

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic principle behind the operation of gears is analogous to the basic principle of levers. A gear may also be known informally as a cog. Geared devices can change the speed, torque, and direction of a power source. Gears of different sizes produce a change in torque, creating a mechanical advantage, through their ''gear ratio'', and thus may be considered a simple machine. The rotational speeds, and the torques, of two meshing gears differ in proportion to their diameters. The teeth on the two meshing gears all have the same shape. Two or more meshing gears, working in a sequence, are called a gear train or a ''transmission''. The gears in a transmission are analogous to the wheels in a crossed, belt pulley system. An advantage of gears is tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compressive

In continuum mechanics, stress is a physical quantity. It is a quantity that describes the magnitude of forces that cause deformation. Stress is defined as ''force per unit area''. When an object is pulled apart by a force it will cause elongation which is also known as deformation, like the stretching of an elastic band, it is called tensile stress. But, when the forces result in the compression of an object, it is called compressive stress. It results when forces like tension or compression act on a body. The greater this force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Therefore, stress is measured in newton per square meter (N/m2) or pascal (Pa). Stress expresses the internal forces that neighbouring particles of a continuous material exert on each other, while strain is the measure of the deformation of the material. For example, when a solid vertical bar is supporting an overhead weight, each particle in the bar pushe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tensile

In physics, tension is described as the pulling force transmitted axially by the means of a string, a rope, chain, or similar object, or by each end of a rod, truss member, or similar three-dimensional object; tension might also be described as the action-reaction pair of forces acting at each end of said elements. Tension could be the opposite of compression. At the atomic level, when atoms or molecules are pulled apart from each other and gain potential energy with a restoring force still existing, the restoring force might create what is also called tension. Each end of a string or rod under such tension could pull on the object it is attached to, in order to restore the string/rod to its relaxed length. Tension (as a transmitted force, as an action-reaction pair of forces, or as a restoring force) is measured in newtons in the International System of Units (or pounds-force in Imperial units). The ends of a string or other object transmitting tension will exert forces on t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of the body. The concept originated with the studies by Archimedes of the usage of levers, which is reflected in his famous quote: "''Give me a lever and a place to stand and I will move the Earth''". Just as a linear force is a push or a pull, a torque can be thought of as a twist to an object around a specific axis. Torque is defined as the product of the magnitude of the perpendicular component of the force and the distance of the line of action of a force from the point around which it is being determined. The law of conservation of energy can also be used to understand torque. The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. When being referred to as moment of force, it is commonly denoted by . I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |