|

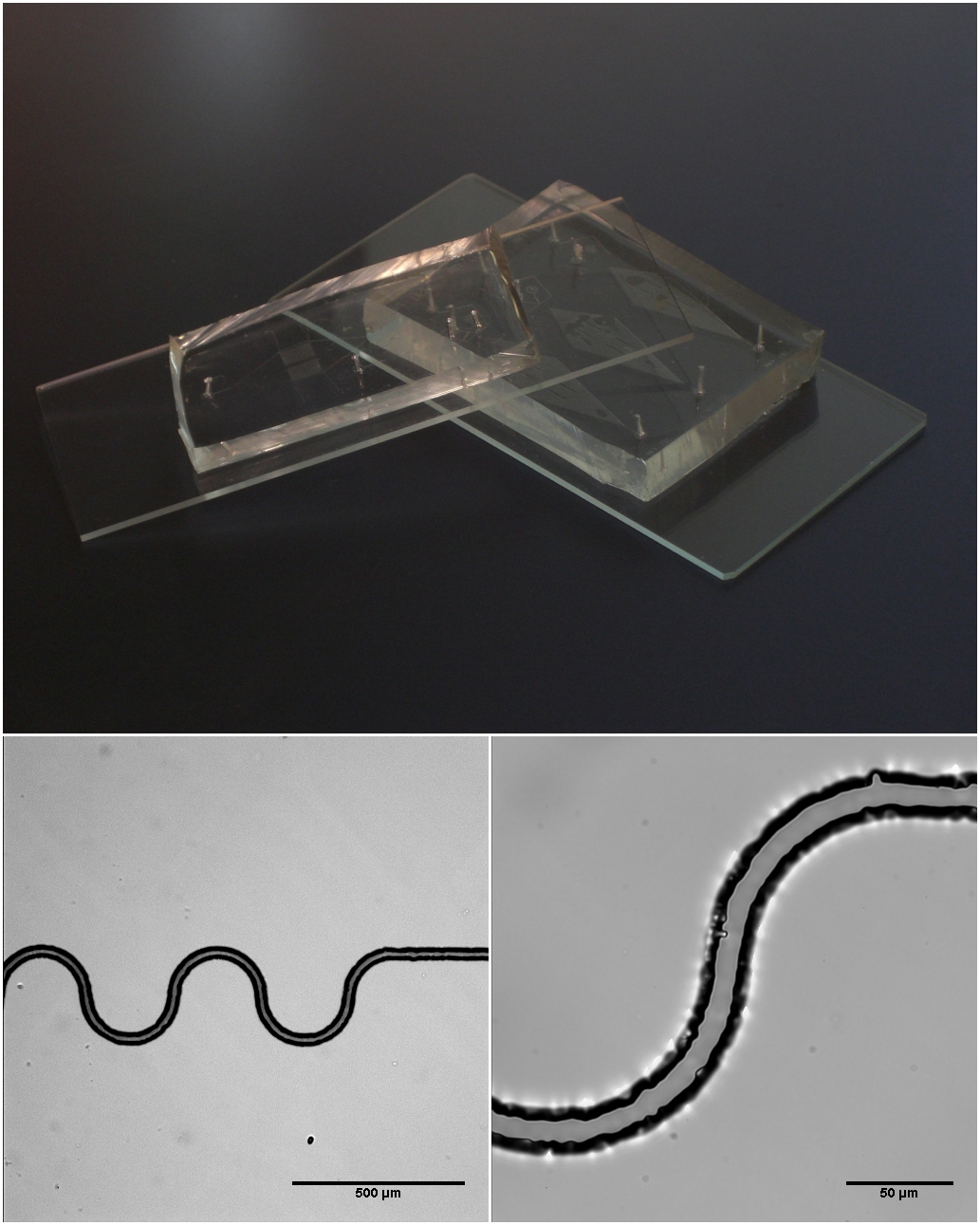

Micro Heat Exchanger

Micro heat exchangers, Micro-scale heat exchangers, or microstructured heat exchangers are heat exchangers in which (at least one) fluid flows in lateral confinements with typical dimensions below 1 mm. The most typical such confinement are microchannel (microtechnology), microchannels, which are channels with a hydraulic diameter below 1 mm. Microchannel heat exchangers can be made from metal or ceramic. Microchannel heat exchangers can be used for many applications including: * high-performance aircraft gas turbine engines * heat pumps * Microprocessor and microchip cooling * air conditioning Background Investigation of microscale thermal devices is motivated by the single phase internal flow correlation for convective heat transfer: :h=\mathit_c \frac Where h is the heat transfer coefficient, \mathit_c is the Nusselt number, k is the thermal conductivity of the fluid and d is the hydraulic diameter of the channel or duct. In internal laminar flows, the Nusselt number b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchangers

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement Image:Heat_exc_1-1.svg, Fig. 1: Shell and tube heat exchanger, single pass (1–1 paral ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reynolds Number

In fluid mechanics, the Reynolds number () is a dimensionless quantity that helps predict fluid flow patterns in different situations by measuring the ratio between inertial and viscous forces. At low Reynolds numbers, flows tend to be dominated by laminar (sheet-like) flow, while at high Reynolds numbers flows tend to be turbulent. The turbulence results from differences in the fluid's speed and direction, which may sometimes intersect or even move counter to the overall direction of the flow (eddy currents). These eddy currents begin to churn the flow, using up energy in the process, which for liquids increases the chances of cavitation. The Reynolds number has wide applications, ranging from liquid flow in a pipe to the passage of air over an aircraft wing. It is used to predict the transition from laminar to turbulent flow and is used in the scaling of similar but different-sized flow situations, such as between an aircraft model in a wind tunnel and the full-size v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microfluidics

Microfluidics refers to the behavior, precise control, and manipulation of fluids that are geometrically constrained to a small scale (typically sub-millimeter) at which surface forces dominate volumetric forces. It is a multidisciplinary field that involves engineering, physics, chemistry, biochemistry, nanotechnology, and biotechnology. It has practical applications in the design of systems that process low volumes of fluids to achieve multiplexing, automation, and high-throughput screening. Microfluidics emerged in the beginning of the 1980s and is used in the development of inkjet printheads, DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies. Typically, micro means one of the following features: * Small volumes (μL, nL, pL, fL) * Small size * Low energy consumption * Microdomain effects Typically microfluidic systems transport, mix, separate, or otherwise process fluids. Various applications rely on passive fluid control using capillary ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microtechnology

Microtechnology deals with technology whose features have dimensions of the order of one micrometre (one millionth of a metre, or 10−6 metre, or 1μm). It focuses on physical and chemical processes as well as the production or manipulation of structures with one-micrometre magnitude. Development Around 1970, scientists learned that by arraying large numbers of microscopic transistors on a single chip, microelectronic circuits could be built that dramatically improved performance, functionality, and reliability, all while reducing cost and increasing volume. This development led to the Information Revolution. More recently, scientists have learned that not only electrical devices, but also mechanical devices, may be miniaturized and batch-fabricated, promising the same benefits to the mechanical world as integrated circuit technology has given to the electrical world. While electronics now provide the ‘brains’ for today's advanced systems and products, micro-mechanical devic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micro Process Engineering

{{Unreferenced, date=June 2019, bot=noref (GreenC bot) Micro process engineering is the science of conducting chemical or physical processes (unit operations) inside small volumina, typically inside channels with diameters of less than 1 mm (microchannels) or other structures with sub-millimeter dimensions. These processes are usually carried out in continuous flow mode, as opposed to batch production, allowing a throughput high enough to make micro process engineering a tool for chemical production. Micro process engineering is therefore not to be confused with microchemistry, which deals with very small overall quantities of matter. The subfield of micro process engineering that deals with chemical reactions, carried out in microstructured reactors or " microreactors", is also known as microreaction technology. The unique advantages of microstructured reactors or '' microreactors'' are enhanced heat transfer due to the large surface area-to-volume ratio, and enhanced mass ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microreactor

A microreactor or microstructured reactor or microchannel reactor is a device in which chemical reactions take place in a confinement with typical lateral dimensions below 1 mm; the most typical form of such confinement are microchannels.''Recent advances in synthetic micro reaction technology'' Paul Watts and Charlotte Wiles Chem. Commun., 2007, 443 - 467, Microreactors are studied in the field of micro process engineering, together with other devices (such as micro heat exchangers) in which physical processes occur. The microreactor is usually a continuous flow reactor (contrast with/to a batch reactor). Microreactors offer many advantages over conventional scale reactors, including vast improvements in energy efficiency, reaction speed and yield, safety, reliability, scalability, on-site/on-demand production, and a much finer degree of process control. History Gas-phase microreactors have a long history but those involving liquids started to appear in the late 1990s. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Countercurrent Exchange

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some chemical, between two flowing bodies flowing in opposite directions to each other. The flowing bodies can be liquids, gases, or even solid powders, or any combination of those. For example, in a distillation column, the vapors bubble up through the downward flowing liquid while exchanging both heat and mass. The maximum amount of heat or mass transfer that can be obtained is higher with countercurrent than co-current (parallel) exchange because countercurrent maintains a slowly declining difference or gradient (usually temperature or concentration difference). In cocurrent exchange the initial gradient is higher but falls off quickly, leading to wasted potential. For example, in the adjacent diagram, the fluid being heated (exiting top) has a higher exiting temperature than the cooled fluid (exiting bottom) that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoelectric Effect

The thermoelectric effect is the direct conversion of temperature differences to electric voltage and vice versa via a thermocouple. A thermoelectric device creates a voltage when there is a different temperature on each side. Conversely, when a voltage is applied to it, heat is transferred from one side to the other, creating a temperature difference. At the atomic scale, an applied temperature gradient causes charge carriers in the material to diffuse from the hot side to the cold side. This effect can be used to generate electricity, measure temperature or change the temperature of objects. Because the direction of heating and cooling is affected by the applied voltage, thermoelectric devices can be used as temperature controllers. The term "thermoelectric effect" encompasses three separately identified effects: the Seebeck effect, Peltier effect, and Thomson effect. The Seebeck and Peltier effects are different manifestations of the same physical process; textbooks may re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Multiphase Flow

In fluid mechanics, multiphase flow is the simultaneous flow of materials with two or more thermodynamic phases. Virtually all processing technologies from cavitating pumps and turbines to paper-making and the construction of plastics involve some form of multiphase flow. It is also prevalent in many natural phenomena. These phases may consist of one chemical component (e.g. flow of water and water vapour), or several different chemical components (e.g. flow of oil and water). A phase is classified as ''continuous'' if it occupies a continually connected region of space (as opposed to ''disperse'' if the phase occupies disconnected regions of space). The continuous phase may be either gaseous or a liquid. The disperse phase can consist of a solid, liquid or gas. Two general topologies can be identified: ''disperse'' flows and ''separated'' flows.'' ''The former consists of finite particles, drops or bubbles distributed within a continuous phase, whereas the latter consists of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Liquid

A liquid is a nearly incompressible fluid that conforms to the shape of its container but retains a (nearly) constant volume independent of pressure. As such, it is one of the four fundamental states of matter (the others being solid, gas, and plasma), and is the only state with a definite volume but no fixed shape. A liquid is made up of tiny vibrating particles of matter, such as atoms, held together by intermolecular bonds. Like a gas, a liquid is able to flow and take the shape of a container. Most liquids resist compression, although others can be compressed. Unlike a gas, a liquid does not disperse to fill every space of a container, and maintains a fairly constant density. A distinctive property of the liquid state is surface tension, leading to wetting phenomena. Water is by far the most common liquid on Earth. The density of a liquid is usually close to that of a solid, and much higher than that of a gas. Therefore, liquid and solid are both termed condensed mat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat

In thermodynamics, heat is defined as the form of energy crossing the boundary of a thermodynamic system by virtue of a temperature difference across the boundary. A thermodynamic system does not ''contain'' heat. Nevertheless, the term is also often used to refer to the thermal energy contained in a system as a component of its internal energy and that is reflected in the temperature of the system. For both uses of the term, heat is a form of energy. An example of formal vs. informal usage may be obtained from the right-hand photo, in which the metal bar is "conducting heat" from its hot end to its cold end, but if the metal bar is considered a thermodynamic system, then the energy flowing within the metal bar is called internal energy, not heat. The hot metal bar is also transferring heat to its surroundings, a correct statement for both the strict and loose meanings of ''heat''. Another example of informal usage is the term '' heat content'', used despite the fact that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement Image:Heat_exc_1-1.svg, Fig. 1: Shell and tube heat exchanger, single pass (1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |