|

List Of Types Of Mill

Types of mill include the following: Manufacturing facilities Categorized by power source * Watermill, a mill powered by moving water * Windmill, a mill powered by moving air (wind) * Tide mill, a water mill that uses the tide's movement * Treadmill or treadwheel, a mill powered by human or animal movement ** Horse mill, a mill powered by horses' movement Categorized by not being a fixed building * Ship mill, a water mill that floats on the river or bay whose current or tide provides the water movement * Field mill (carriage), a portable mill Categorized by what is made and/or acted on * Rice mill, processes paddy to rice * Bark mill, produces tanbark for tanneries * Coffee mill * Colloid mill * Cider mill, crushes apples to give cider * Flotation mill, in mining, uses grinding and froth flotation to concentrate ores using differences in materials' hydrophobicity * Gristmill, a grain mill (flour mill) * Herb grinder * Oil mill, see expeller pressing, extrusion * Ore mill, for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Watermill

A watermill or water mill is a mill that uses hydropower. It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering. Such processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may comprise gristmills, sawmills, paper mills, textile mills, hammermills, trip hammering mills, rolling mills, wire drawing mills. One major way to classify watermills is by wheel orientation (vertical or horizontal), one powered by a vertical waterwheel through a gear mechanism, and the other equipped with a horizontal waterwheel without such a mechanism. The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and pitchback (backshot or reverse shot) waterwheel mills. Another way to classify water mills is by an essential trait about their location: tide ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded mater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

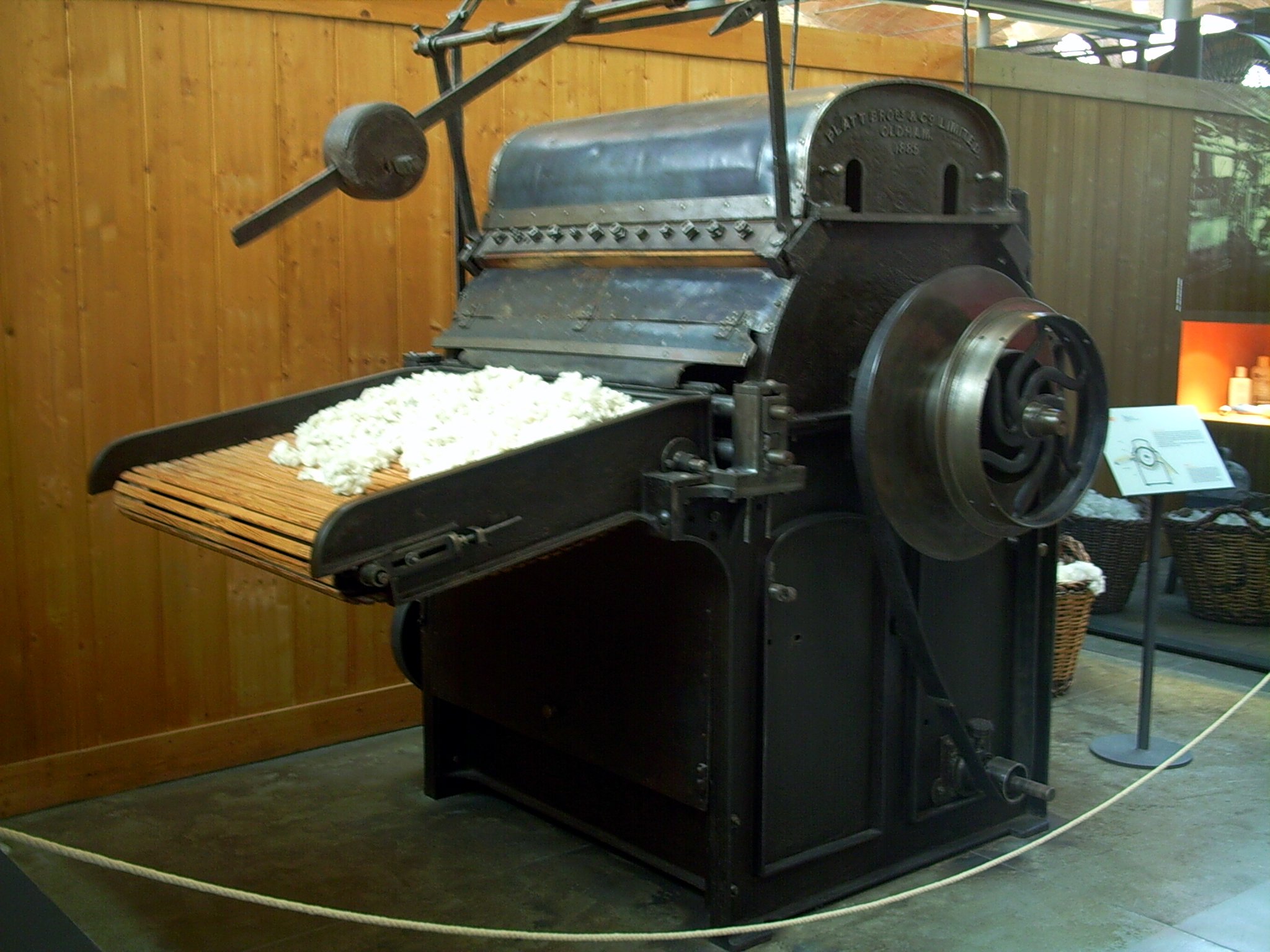

Textile Manufacturing

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most widely used and common natural fiber making up 90% of all-natural fibers used in the textile industry. People often use cotton clothing and accessories because of comfort, not limited to different weathers. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. History Textile manufacturing in the modern era is an evolved form of the art and craft industries. Until the 18th and 19th centuries, the textile industry was a household work. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sugar Refinery

A sugar refinery is a refinery which processes raw sugar from cane or beets into white refined sugar. Many cane sugar mills produce raw sugar, which is sugar that still contains molasses, giving it more colour (and impurities) than the white sugar which is normally consumed in households and used as an ingredient in soft drinks and foods. While cane sugar does not need refining to be palatable, sugar from sugar beet is almost always refined to remove the strong, usually unwanted, taste of beets from it. The refined sugar produced is more than 99 percent pure sucrose. Many sugar mills only operate during the harvest season, whereas refineries may work the year round. Sugar beet refineries tend to have shorter periods when they process beet than cane refineries, but may store intermediate product and process it in the off-season. Raw sugar is either processed and sold locally, or is exported and refined elsewhere. History Sugar refineries date back to Arab Egypt in the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sugar Mill

A sugar cane mill is a factory that processes sugar cane to produce raw or white sugar. The term is also used to refer to the equipment that crushes the sticks of sugar cane to extract the juice. Processing There are a number of steps in producing raw sugar from cane: # Cane receiving and unloading (receive the cane at the factory and unload it from the transport vehicles) # Cane preparation (cutting and shredding cane to prepare it for juice extraction) # Juice extraction (two technologies are in common use; milling or diffusion) # Juice clarification (remove suspended solids from the juice, typically mud, waxes, fibres) # Juice evaporation (to concentrate the juice to a thick syrup of about 65°brix) # Syrup clarification (remove suspended solids from the syrup, typically colloid size of mud, waxes, fibres, etc.) # Crystallisation # Centrifugation (Separation of the sugar crystals from the mother liquor, done by centrifugal machines) # Sugar drying # Packaging and delivery ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel Mill

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also be a plant where steel semi-finished casting products are made from molten pig iron or from scrap. History Since the invention of the Bessemer process, steel mills have replaced ironworks, based on puddling or fining methods. New ways to produce steel appeared later: from scrap melted in an electric arc furnace and, more recently, from direct reduced iron processes. In the late 19th and early 20th centuries the world's largest steel mill was the Barrow Hematite Steel Company steelworks located in Barrow-in-Furness, United Kingdom. Today, the world's largest steel mill is in Gwangyang, South Korea. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Starch Mill

Starch or amylum is a polymeric carbohydrate consisting of numerous glucose units joined by glycosidic bonds. This polysaccharide is produced by most green plants for energy storage. Worldwide, it is the most common carbohydrate in human diets, and is contained in large amounts in staple foods such as wheat, potatoes, maize (corn), rice, and cassava (manioc). Pure starch is a white, tasteless and odorless powder that is insoluble in cold water or alcohol. It consists of two types of molecules: the linear and helical amylose and the branched amylopectin. Depending on the plant, starch generally contains 20 to 25% amylose and 75 to 80% amylopectin by weight. Glycogen, the energy reserve of animals, is a more highly branched version of amylopectin. In industry, starch is often converted into sugars, for example by malting. These sugars may be fermented to produce ethanol in the manufacture of beer, whisky and biofuel. In addition, sugars produced from processed starch are us ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sawmill

A sawmill (saw mill, saw-mill) or lumber mill is a facility where logging, logs are cut into lumber. Modern sawmills use a motorized saw to cut logs lengthwise to make long pieces, and crosswise to length depending on standard or custom sizes (dimensional lumber). The Portable sawmill, "portable" sawmill is of simple operation. The log lies flat on a steel bed, and the motorized saw cuts the log horizontally along the length of the bed, by the operator manually pushing the saw. The most basic kind of sawmill consists of a chainsaw and a customized jig ("Alaskan sawmill"), with similar horizontal operation. Before the invention of the sawmill, boards were made in various manual labour, manual ways, either wood splitting, rived (split) and plane (tool), planed, hewing, hewn, or more often hand sawn by two men with a whipsaw, one above and another in a saw pit below. The earliest known mechanical mill is the Hierapolis sawmill, a Roman water-powered stone mill at Hierapolis, Asia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sugar Cane Mill

A sugar cane mill is a factory that processes sugar cane to produce raw or white sugar. The term is also used to refer to the equipment that crushes the sticks of sugar cane to extract the juice. Processing There are a number of steps in producing raw sugar from cane: # Cane receiving and unloading (receive the cane at the factory and unload it from the transport vehicles) # Cane preparation (cutting and shredding cane to prepare it for juice extraction) # Juice extraction (two technologies are in common use; milling or diffusion) # Juice clarification (remove suspended solids from the juice, typically mud, waxes, fibres) # Juice evaporation (to concentrate the juice to a thick syrup of about 65°brix) # Syrup clarification (remove suspended solids from the syrup, typically colloid size of mud, waxes, fibres, etc.) # Crystallisation # Centrifugation (Separation of the sugar crystals from the mother liquor, done by centrifugal machines) # Sugar drying # Packaging and delivery ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rock Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Crushing is the process of transferring a force amplified by mechanical advantage through a material made of molecules that bond together more strongly, and resist deformation more, than those in the material being crushed do. Crushing devices hold material between two parallel or tangent solid surfaces, and apply sufficient force to bring the surfaces together to generate enough energy within the material being crushed so that its molecules separate from (fracturing), or change alignment in relation to (deformation), each other. The earliest crushers were hand-held stones, where the weight of the stone provided a boost ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Puppy Mill

A puppy mill, also known as a puppy farm, is a commercial dog breeding facility characterized by quick breeding and poor conditions. Although no standardized legal definition for "puppy mill" exists, a definition was established in ''Avenson v. Zegart'' in 1984 as "a dog breeding operation in which the health of the mill’s dogs are disregarded to maintain a low overhead and maximize profits". The Veterinary Medical Association of the Humane Society of the United States defines the main characteristics of a puppy mill as "emphasis on quantity over quality, indiscriminate breeding, continuous confinement, lack of human contact and environmental enrichment, poor husbandry, and minimal to no veterinary care." There are an estimated 10,000 licensed and unlicensed puppy mills in the United States, in total selling more than 2,000,000 puppies annually. The term "mill" is also applied to operations involving other animals bred for profit, including cats. For-profit breeding on a smalle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Powder Mill

A powder mill was a mill where gunpowder is made from sulfur, saltpeter and charcoal. Milling steps Crude grinding and mixing operations such as the Frankford Powder-Mill of Philadelphia were a cottage industry until the industrial revolution brought improved product quality through the following procedures: * Charcoal was often manufactured nearby from locally available trees, but the heating retorts were typically separated from the other buildings to minimize fire danger. Trees with low value as sources of lumber were debarked, dried, and cut to uniform length to fit into iron retorts with cast iron doors. The retorts were carefully packed to leave as little air space as possible, and the retort doors were closed and sealed with clay to prevent entry of air as the retorts were heated by external fires. Volatile gas generated by the heating process was vented through a small flue at the top of each retort. After the external fires were extinguished, the retorts were allowe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |