|

Lateral Epitaxial Overgrowth And Pendeo-epitaxy

Epitaxy refers to a type of crystal growth or material deposition in which new crystalline layers are formed with one or more well-defined orientations with respect to the crystalline seed layer. The deposited crystalline film is called an epitaxial film or epitaxial layer. Epitaxial growth and semiconductor device fabrication are technologies used to develop stacked crystalline layers of different materials with specific semiconductor properties on a crystalline substrate, commonly silicon or silicon carbide (SiC) materials, to achieve the desired performance of the microelectronic devices, such as transistors and diodes. The crystal structure of these layers is with high density of imperfections, such as dislocations and stacking faults. Therefore the microelectronic engineers and technologists have developed different techniques to eliminate or minimize the density of these structural defects in order to improve the microelectronic devices operation. One such approach is Selectiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epitaxy

Epitaxy (prefix ''epi-'' means "on top of”) is a type of crystal growth or material deposition in which new crystalline layers are formed with one or more well-defined orientations with respect to the crystalline seed layer. The deposited crystalline film is called an epitaxial film or epitaxial layer. The relative orientation(s) of the epitaxial layer to the seed layer is defined in terms of the orientation of the crystal lattice of each material. For most epitaxial growths, the new layer is usually crystalline and each crystallographic domain of the overlayer must have a well-defined orientation relative to the substrate crystal structure. Epitaxy can involve single-crystal structures, although grain-to-grain epitaxy has been observed in granular films. For most technological applications, single-domain epitaxy, which is the growth of an overlayer crystal with one well-defined orientation with respect to the substrate crystal, is preferred. Epitaxy can also play an important ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

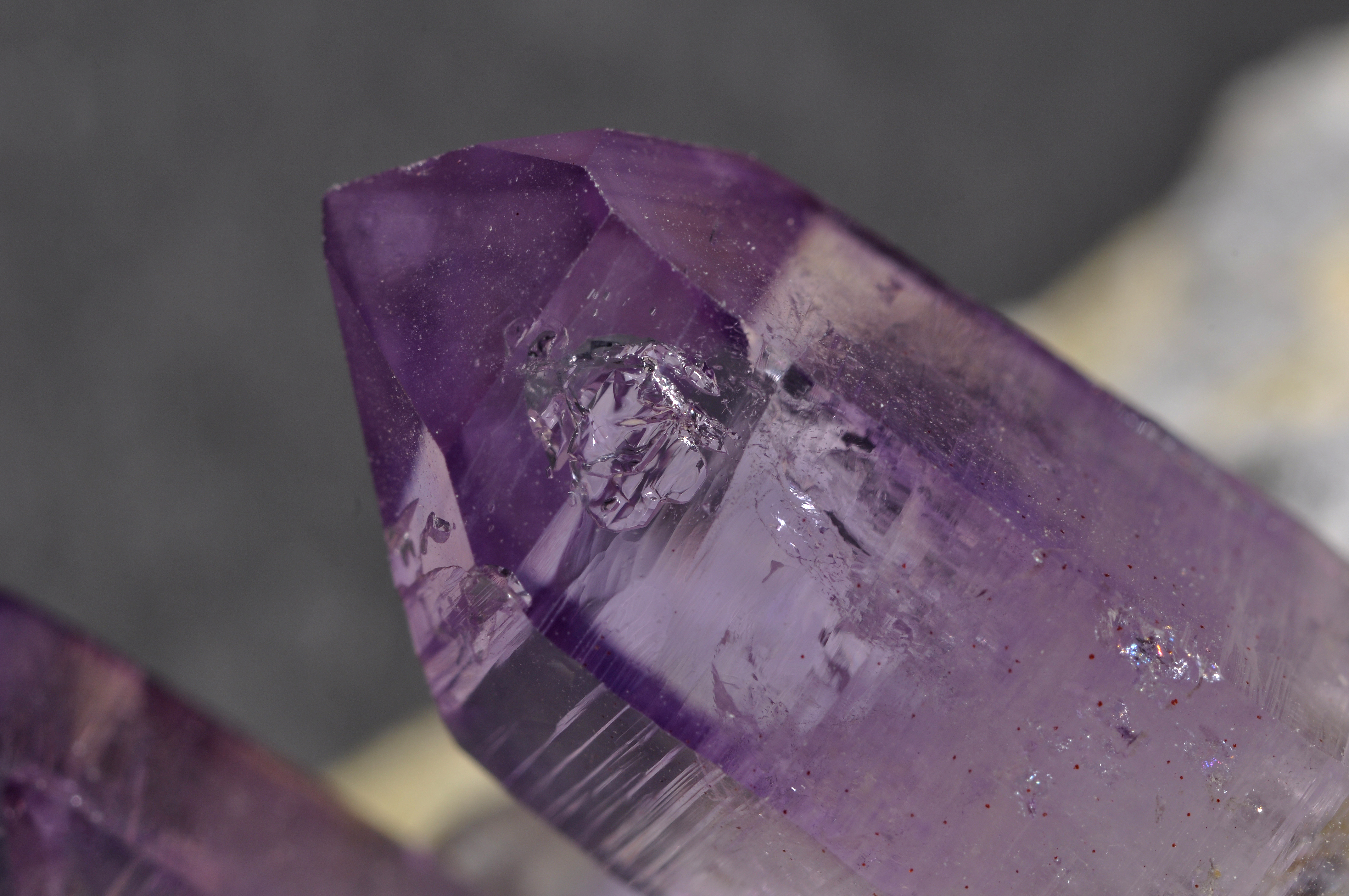

Crystal

A crystal or crystalline solid is a solid material whose constituents (such as atoms, molecules, or ions) are arranged in a highly ordered microscopic structure, forming a crystal lattice that extends in all directions. In addition, macroscopic single crystals are usually identifiable by their geometrical shape, consisting of flat faces with specific, characteristic orientations. The scientific study of crystals and crystal formation is known as crystallography. The process of crystal formation via mechanisms of crystal growth is called crystallization or solidification. The word ''crystal'' derives from the Ancient Greek word (), meaning both "ice" and " rock crystal", from (), "icy cold, frost". Examples of large crystals include snowflakes, diamonds, and table salt. Most inorganic solids are not crystals but polycrystals, i.e. many microscopic crystals fused together into a single solid. Polycrystals include most metals, rocks, ceramics, and ice. A third cat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A wide bandgap semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications requiring high endurance, such as car brakes, car clutches and ceramic plates in bulletproof vests. Large single crystals of silicon carbide can be grown by the Lely method and they can be cut into gems known as synthetic moissanite. Electronic applications of silicon carbide such as light-emitting diodes (LEDs) and Cat's whisker detector, detectors in early radios were first demonstrated around 1907. SiC is used in semiconductor electronics devices that operate at high temperatures or high voltages, or both. Natural occurrence Naturally occurring moissanite is found ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Selective Area Epitaxy

Selective area epitaxy is the local growth of Epitaxy, epitaxial layer through a patterned amorphous dielectric mask (typically Silicon dioxide, SiO2 or Silicon nitride, Si3N4) deposited on a semiconductor substrate. Semiconductor growth conditions are selected to ensure epitaxial growth on the exposed substrate, but not on the dielectric mask. SAE can be executed in various epitaxial growth methods such as Molecular-beam epitaxy, molecular beam epitaxy (MBE), Metalorganic vapour-phase epitaxy, metalorganic vapour phase epitaxy (MOVPE) and chemical beam epitaxy (CBE). By SAE, semiconductor nanostructures such as quantum dots and nanowires can be grown to their designed places. Concepts Mask The mask used in SAE is usually amorphous dielectric such as SiO2 or SiN4 which is deposited on the semiconductor substrate. The patterns (holes) in the mask are fabricated using standard microfabrication techniques lithography and etching. Variety of lithography and etching techniques can ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wide-bandgap Semiconductor

Wide-bandgap semiconductors (also known as WBG semiconductors or WBGSs) are semiconductor materials which have a larger band gap than conventional semiconductors. Conventional semiconductors like silicon and selenium have a bandgap in the range of 0.7 – 1.5 electronvolt (eV), whereas wide-bandgap materials have bandgaps in the range above 2 eV. Generally, wide-bandgap semiconductors have electronic properties which fall in between those of conventional semiconductors and insulators. Wide-bandgap semiconductors permit devices to operate at much higher voltages, frequencies, and temperatures than conventional semiconductor materials like silicon and gallium arsenide. They are the key component used to make short-wavelength (green-UV) LEDs or lasers, and are also used in certain radio frequency applications, notably military radars. Their intrinsic qualities make them suitable for a wide range of other applications, and they are one of the leading contenders ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gallium Nitride

Gallium nitride () is a binary III/ V direct bandgap semiconductor commonly used in blue light-emitting diodes since the 1990s. The compound is a very hard material that has a Wurtzite crystal structure. Its wide band gap of 3.4 eV affords it special properties for applications in optoelectronics, high-power and high-frequency devices. For example, GaN is the substrate that makes violet (405 nm) laser diodes possible, without requiring nonlinear optical frequency doubling. Its sensitivity to ionizing radiation is low (like other group III nitrides), making it a suitable material for solar cell arrays for satellites. Military and space applications could also benefit as devices have shown stability in high-radiation environments. Because GaN transistors can operate at much higher temperatures and work at much higher voltages than gallium arsenide (GaAs) transistors, they make ideal power amplifiers at microwave frequencies. In addition, GaN offers promising c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor Device Fabrication

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuits (ICs) such as microprocessors, microcontrollers, and memories (such as Random-access memory, RAM and flash memory). It is a multiple-step Photolithography, photolithographic and physico-chemical process (with steps such as thermal oxidation, thin-film deposition, ion-implantation, etching) during which electronic circuits are gradually created on a wafer (electronics), wafer, typically made of pure single-crystal semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications. This article focuses on the manufacture of integrated circuits, however steps such as etching and photolithography can be used to manufacture other devices such as LCD and OLED displays. The fabrication process is performed in highly specialized semiconductor fabrication plants, also called foundries or "fabs", with the cen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or Slip (materials science), slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plasticity (physics), Plastic deformation of a material occurs by the creation and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stacking Fault

In crystallography, a stacking fault is a planar defect that can occur in crystalline materials.Fine, Morris E. (1921). "Introduction to Chemical and Structural Defects in Crystalline Solids", in ''Treatise on Solid State Chemistry Volume 1'', Springer. Crystalline materials form repeating patterns of layers of atoms. Errors can occur in the sequence of these layers and are known as stacking faults. Stacking faults are in a higher energy state which is quantified by the formation enthalpy per unit area called the stacking-fault energy. Stacking faults can arise during crystal growth or from plastic deformation. In addition, dislocations in low stacking-fault energy materials typically dissociate into an ''extended dislocation'', which is a stacking fault bounded by partial dislocations. The most common example of stacking faults is found in close-packed crystal structures. Face-centered cubic (fcc) structures differ from hexagonal close packed (hcp) structures only in stacking ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fig 1 - LEO-GaN

The fig is the edible fruit of ''Ficus carica'', a species of tree or shrub in the flowering plant family Moraceae, native to the Mediterranean region, together with western and southern Asia. It has been cultivated since ancient times and is now widely grown throughout the world.''The Fig: its History, Culture, and Curing'', Gustavus A. Eisen, Washington, Govt. print. off., 1901 ''Ficus carica'' is the type species of the genus ''Ficus'', which comprises over 800 tropical and subtropical plant species. A fig plant is a deciduous tree or large shrub, growing up to tall, with smooth white bark. Its large leaves have three to five deep lobes. Its fruit (referred to as syconium, a type of is tear-shaped, long, with a green fruit that may ripen toward purple or brown, and sweet soft reddish flesh containing numerous crunchy seeds. The milky sap of the green parts is an irritant to human skin. In the Northern hemisphere, fresh figs are in season from late August to early October ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalorganic Vapour-phase Epitaxy

Metalorganic vapour-phase epitaxy (MOVPE), also known as organometallic vapour-phase epitaxy (OMVPE) or metalorganic chemical vapour deposition (MOCVD), is a chemical vapour deposition method used to produce single- or polycrystalline thin films. It is a process for growing crystalline layers to create complex semiconductor multilayer structures. In contrast to molecular-beam epitaxy (MBE), the growth of crystals is by chemical reaction and not physical deposition. This takes place not in vacuum, but from the gas phase at moderate pressures (10 to 760 Torr). As such, this technique is preferred for the formation of devices incorporating thermodynamically metastable alloys, and it has become a major process in the manufacture of optoelectronics, such as light-emitting diodes, its most widespread application. It was first demonstrated in 1967 at North American Aviation (later Rockwell International) Autonetics Division in Anaheim CA by Harold M. Manasevit. Basic pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydride Vapour-phase Epitaxy

Hydride vapour-phase epitaxy (HVPE) is an epitaxial growth technique often employed to produce semiconductors such as GaN, GaAs, InP and their related compounds, in which hydrogen chloride is reacted at elevated temperature with the group-III metals to produce gaseous metal chlorides, which then react with ammonia to produce the group-III nitrides. Carrier gasses commonly used include ammonia, hydrogen and various chlorides. HVPE technology can significantly reduce the cost of production compared to the most common method of vapor deposition of organometallic compounds (MOCVD Metalorganic vapour-phase epitaxy (MOVPE), also known as organometallic vapour-phase epitaxy (OMVPE) or metalorganic chemical vapour deposition (MOCVD), is a chemical vapour deposition method used to produce single- or polycrystalline thin films. ...). Cost reduction is achieved by significantly reducing the consumption of NH3, cheaper source materials than in MOCVD, reducing the capital equipment costs, due ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |