|

In-circuit Test

In-circuit testing (ICT) is an example of white box testing where an electrical probe tests a populated printed circuit board (PCB), checking for shorts, opens, resistance, capacitance, and other basic quantities which will show whether the assembly was correctly fabricated. It may be performed with a "bed of nails" test fixture and specialist test equipment, or with a fixtureless in-circuit test setup. In-Circuit Test (ICT) is a widely used and cost-efficient method for testing medium- to high-volume electronic printed circuit board assemblies (PCBAs). It has maintained its popularity over the years due to its ability to diagnose component-level faults and its operational speed. Using In-Circuit Test fixtures is a very effective way of maintaining standards when carrying out tests. It can help to reduce production downtime by identifying faults early in the testing process, ensuring that defective products are removed from the production line and fixed. Fixtures for in-circu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

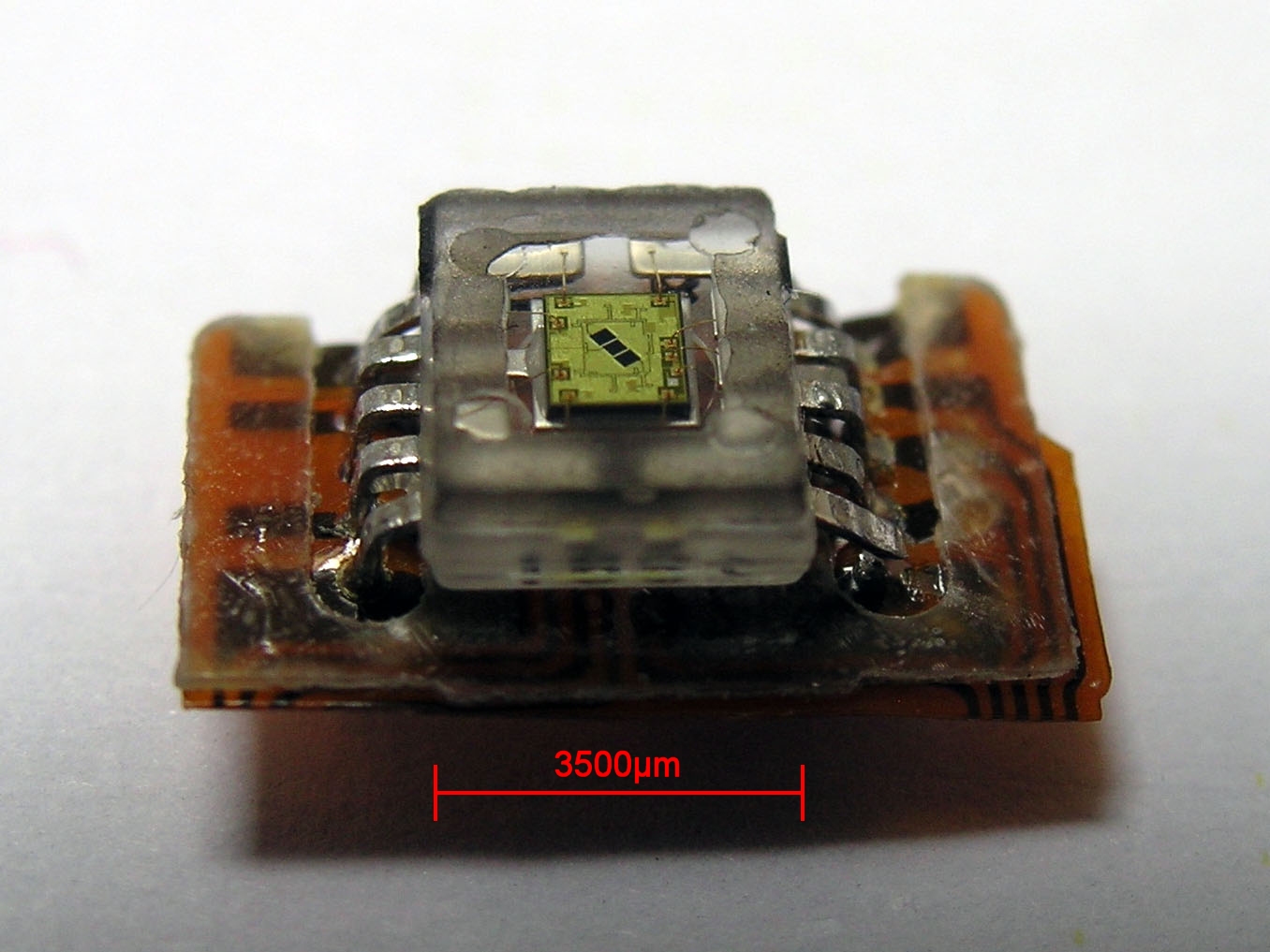

Bead Probe Technology

Bead probe technology (BPT) is technique used to provide electrical access (called “nodal access”) to printed circuit board (PCB) circuitry for performing In-circuit test, in-circuit testing (ICT). It makes use of small beads of solder placed onto the board's Printed circuit board#Patterning, traces to allow measuring and controlling of the signals using a test probe. This permits test access to boards on which standard ICT test pads are not feasible due to space constraints. Description Bead probe technology is a probing method used to connect electronic test equipment to the device under test (DUT) within a In-circuit test#Bed of nails tester, bed of nails fixture. The technique was first used in the 1990s and originally given the name “Waygood Bump” after one of the main proponents, Rex Waygood. They are also commonly referred to as solder bumps. Bead probes were designed for when less than 30 Thou (length), mil is available for test probe points on the PCB. They a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Printed Circuit Board Manufacturing

Printed circuit board manufacturing is the process of manufacturing bare printed circuit board, printed circuit boards (PCBs) and populating them with electronic components. It includes all the processes to produce the full assembly of a board into a functional circuit board. In board manufacturing, multiple PCBs are grouped on a single panel for efficient processing. After assembly, they are separated (depaneled). Various techniques, such as silk screening and photoengraving, replicate the desired copper patterns on the PCB layers. Multi-layer boards are created by laminating different layers under heat and pressure. Holes for Via (electronics), vias (vertical connections between layers) are also drilled. The final assembly involves placing components onto the PCB and soldering them in place. This process can include through-hole technology (in which the component goes through the board) or surface-mount technology (SMT) (in which the component lays on top of the board). Design ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

FCT (test)

In manufacturing, functional testing (FCT) is performed during the last phase of the production line. This is often referred to as a final quality control test, which is done to ensure that specifications are carried out by FCTs. The process of FCTs is entailed by the emulation or simulation of the environment in which a product is expected to operate. This is done so to check, and correct any issues with functionality. The environment involved with FCTs consists of any device that communicates with an DUT, the power supply of said DUT, and any loads needed to make the DUT function correctly. Functional tests are performed in an automatic fashion by production line operators using test software. In order for this to be completed, the software will communicate with any external programmable instruments such as I/O boards, digital multimeters, and communication ports. In conjunction with the test fixture, the software that interfaces with the DUT is what makes it possible for a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Acceptance Testing

In engineering and its various subdisciplines, acceptance testing is a test conducted to determine if the requirements of a specification or contract are met. It may involve chemical tests, physical tests, or performance tests. In systems engineering, it may involve black-box testing performed on a system (for example: a piece of software, lots of manufactured mechanical parts, or batches of chemical products) prior to its delivery. In software testing, the ISTQB defines ''acceptance testing'' as: The final test in the QA lifecycle, user acceptance testing, is conducted just before the final release to assess whether the product or application can handle real-world scenarios. By replicating user behavior, it checks if the system satisfies business requirements and rejects changes if certain criteria are not met. Some forms of acceptance testing are, user acceptance testing (UAT), end-user testing, operational acceptance testing (OAT), acceptance test-driven developm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Automated Optical Inspection

Automated optical inspection (AOI) is an automated visual inspection of printed circuit board (PCB) (or LCD, transistor) manufacture where a camera machine vision, autonomously scans the device under test for both catastrophic failure (e.g. missing component) and Product defect, quality defects (e.g. fillet size or shape or component skew). It is commonly used in the manufacturing process because it is a non-contact test method. It is implemented at many stages through the manufacturing process including bare board inspection, solder paste inspection (SPI), pre-reflow and post-re-flow as well as other stages. Historically, the primary place for AOI systems has been after solder re-flow or "post-production." Mainly because, post-re-flow AOI systems can inspect for most types of defects (component placement, solder shorts, missing solder, etc.) at one place in the line with one single system. In this way the faulty boards are reworked and the other boards are sent to the next process ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Boundary Scan

Boundary scan is a method for testing interconnects (wire lines) on printed circuit boards or sub-blocks inside an integrated circuit (IC). Boundary scan is also widely used as a debugging method to watch integrated circuit pin states, measure voltage, or analyze sub-blocks inside an integrated circuit. The Joint Test Action Group (JTAG) developed a specification for boundary scan testing that was standardized in 1990 as the IEEE Std. 1149.1-1990. In 1994, a supplement that contains a description of the boundary scan description language (BSDL) was added which describes the boundary-scan logic content of IEEE Std 1149.1 compliant devices. Since then, this standard has been adopted by electronic device companies all over the world. Boundary scan is now mostly synonymous with JTAG.IEEE Std 1149.1 (JTAG) Testability ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Joint Test Action Group

JTAG (named after the Joint Test Action Group which codified it) is an industry standard for verifying designs of and testing printed circuit boards after manufacture. JTAG implements standards for on-chip instrumentation in electronic design automation (EDA) as a complementary tool to digital simulation. It specifies the use of a dedicated debug port implementing a serial communications interface for low-overhead access without requiring direct external access to the system address and data buses. The interface connects to an on-chip Test Access Port (TAP) that implements a stateful protocol to access a set of test registers that present chip logic levels and device capabilities of various parts. The Joint Test Action Group formed in 1985 to develop a method of verifying designs and testing printed circuit boards after manufacture. In 1990 the Institute of Electrical and Electronics Engineers codified the results of the effort in IEEE Standard 1149.1-1990, entitled ''Standar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Automated X-ray Inspection

Automated inspection (AXI) is a technology based on the same principles as automated optical inspection (AOI). It uses as its source, instead of visible light, to automatically inspect features, which are typically hidden from view. Automated X-ray inspection is used in a wide range of industries and applications, predominantly with two major goals: # Process optimization, i.e. the results of the inspection are used to optimize following processing steps, # Anomaly detection, i.e. the result of the inspection serve as a criterion to reject a part (for scrap or re-work). While AOI is mainly associated with electronics manufacturing (due to widespread use in printed circuit board manufacturing), AXI has a much wider range of applications. It ranges from the quality check of alloy wheels to the detection of bone fragments in processed meat. Wherever large numbers of very similar items are produced according to a defined standard, automatic inspection using advanced image processin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

PCB Electrical Test

A printed circuit board (PCB), also called printed wiring board (PWB), is a laminated sandwich structure of conductive and insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or "wire" components to one another in an electronic circuit. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side. Printed circuit boards are used in nearly all electronic products today. Alternatives to PCBs include wire wrap and point-to-point construction, both once popular but now rarely used ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Design For Test

Design for testing or design for testability (DFT) consists of integrated circuit design techniques that add testability features to a hardware product design. The added features make it easier to develop and apply manufacturing tests to the designed hardware. The purpose of manufacturing tests is to validate that the product hardware contains no manufacturing defects that could adversely affect the product's correct functioning. Tests are applied at several steps in the hardware manufacturing flow and, for certain products, may also be used for hardware maintenance in the customer's environment. The tests are generally driven by test programs that execute using automatic test equipment (ATE) or, in the case of system maintenance, inside the assembled system itself. In addition to finding and indicating the presence of defects (i.e., the test fails), tests may be able to log diagnostic information about the nature of the encountered test fails. The diagnostic information can be u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Photodetector

Photodetectors, also called photosensors, are devices that detect light or other forms of electromagnetic radiation and convert it into an electrical signal. They are essential in a wide range of applications, from digital imaging and optical communication to scientific research and industrial automation. Photodetectors can be classified by their mechanism of detection, such as the photoelectric effect, photochemical reactions, or thermal effects, or by performance metrics like spectral response. Common types include photodiodes, phototransistors, and photomultiplier tubes, each suited to specific uses. Solar cells, which convert light into electricity, are also a type of photodetector. This article explores the principles behind photodetectors, their various types, applications, and recent advancements in the field. History The development of photodetectors began with the discovery of the photoelectric effect by Heinrich Hertz in 1887, later explained by Albert Einst ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |