|

Fiberglass Sheet Laminating

Fiberglass sheet laminating is the process of taking a thin fiberglass sheet and laminating it to another material in order to provide strength and support to that material. Process characteristics Fiberglass is composed of very fine strands of glass. It has many different purposes, one of which is used for strength. The strength of fiberglass depends on the size of the glass strands, the temperature, and the humidity. Materials needed Fiberglass sheet, resin A resin is a solid or highly viscous liquid that can be converted into a polymer. Resins may be biological or synthetic in origin, but are typically harvested from plants. Resins are mixtures of organic compounds, predominantly terpenes. Commo ..., wood or metal roller, brush or other tool to spread epoxy, material to be strengthened Process description Start by applying the epoxy to the fiberglass sheet. Continue carefully but quickly until all areas are sufficiently covered by the epoxy. Next, start at one end of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiberglass

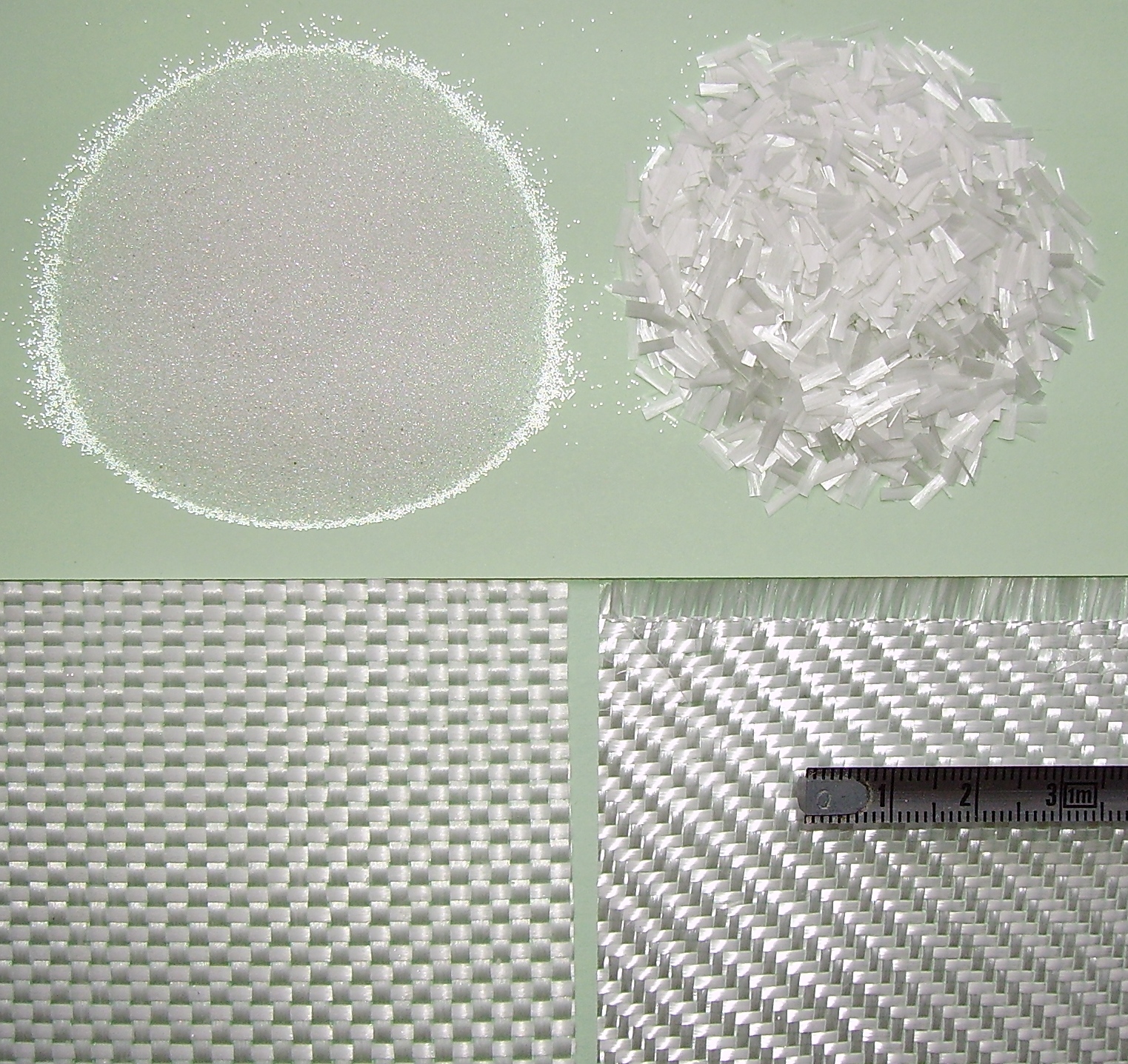

Fiberglass (American English) or fibreglass (English in the Commonwealth of Nations, Commonwealth English) is a common type of fibre-reinforced plastic, fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic Matrix (composite), matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic. Cheaper and more flexible than Carbon-fiber-reinforced polymers, carbon fiber, it is stronger than many metals by weight, non-magnetic, non-conductive, transparent to electromagnetic radiation, can be molded into complex shapes, and is chemically inert under many circumstances. Applications include aircraft, boats, automobiles, bath tubs and enclosures, swimming pools, hot tubs, septic tanks, water tanks, roofing, pipes, cladding, orthopedic casts, surfboards, and external door skins ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laminating

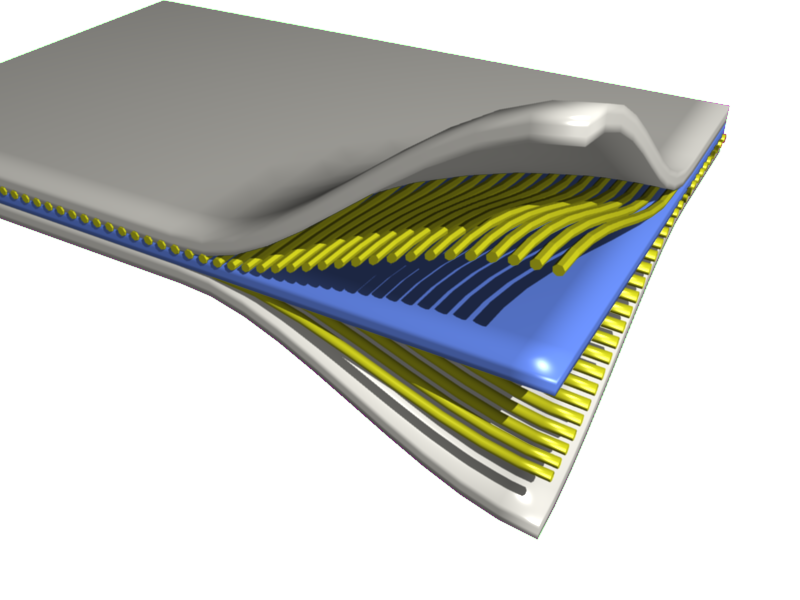

Simulated flight (using image stack created by μCT scanning) through the length of a knitting needle that consists of laminated wooden layers: the layers can be differentiated by the change of direction of the wood's vessels Shattered windshield lamination keeps shards in place Laminate flooring A flexible thin-film solar cell for aerospace use (2007) Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a layered object or material assembled using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used. Lamination may be applied to textiles, glass, wood, or other materials. Laminating paper in plastic makes it sturdy, waterproof, and erasable. Laminating metals and electronic component ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resin

A resin is a solid or highly viscous liquid that can be converted into a polymer. Resins may be biological or synthetic in origin, but are typically harvested from plants. Resins are mixtures of organic compounds, predominantly terpenes. Common resins include amber, hashish, frankincense, myrrh and the animal-derived resin, shellac. Resins are used in varnishes, adhesives, food additives, incenses and perfumes. Resins protect plants from insects and pathogens, and are secreted in response to injury. Resins repel herbivores, insects, and pathogens, while the volatile natural phenol, phenolic compounds may attract benefactors such as predators of insects that attack the plant. Composition Most plant resins are composed of terpenes. Specific components are alpha-Pinene, alpha-pinene, pinene, beta-pinene, carene, delta-3 carene, and sabinene, the monocyclic terpenes limonene and terpinolene, and smaller amounts of the tricyclic sesquiterpenes, longifolene, caryophyllene, and cad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Materials

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Composite materials with more than one distinct layer are called ''composite laminates''. Typical engineered composite materials are made up of a binding agent forming the ''matrix'' and a Filler (materials), filler material (particulates or fibres) giving ''substance'', e.g.: * Concrete, reinforced concrete and masonry with cement, lime or Mortar (masonry), mortar (which is itself a composite material) as a binder * Composite wood such as glulam and plywood with wood glue as a binder * Reinforced plastics, such as fiberglass and fibre-rein ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |