|

Design Review Based On Failure Mode

Design review based on failure mode (DRBFM) is a tool originally developed by the Toyota Motor Corporation. This tool was developed based on the philosophy that design problems occur when changes are made to existing engineering designs that have already been proven successful. Methodology DRBFM methodology was developed by Tatsuhiko Yoshimura, a Quality Expert and a professor at Japan's Kyushu University. Yoshimura knew that design problems occur when changes are made without the proper level of supporting documentation. Using the philosophy of ''preventative measures'' (Mizenboushi), he created his own philosophy of DRBFM. Dr. Tatsuhiko Yoshimura supported the development and usage of DRBFM at many companies. He believes companies that implement the usage of DRBFM will be a better company. He believes the implementation of DRBFM requires discipline and engagement of everyone to the one goal of adding value to the customer by meeting engineering functional requirements and customer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kyushu University

, abbreviated to , is a Japanese national university located in Fukuoka, on the island of Kyushu. It was the 4th Imperial University in Japan, ranked as 4th in 2020 Times Higher Education Japan University Rankings, one of the top 10 Designated National University and selected as a Top Type university of Top Global University Project by the Japanese government. Kyudai is considered one of the most prestigious research-oriented universities in Japan and is a member of the Alliance of Asian Liberal Arts Universities along with the University of Tokyo, Waseda University, Peking University and others. The history of Kyushu University can be traced back to the medical schools of the Fukuoka Domain (福岡藩 Fukuoka han) established in 1867. The school was reorganized to Fukuoka Medical College of Kyoto Imperial University in 1903 and became independent as Kyushu Imperial University in 1911. Albert Einstein visited the university on December 25, 1922. There are 2,089 foreign st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

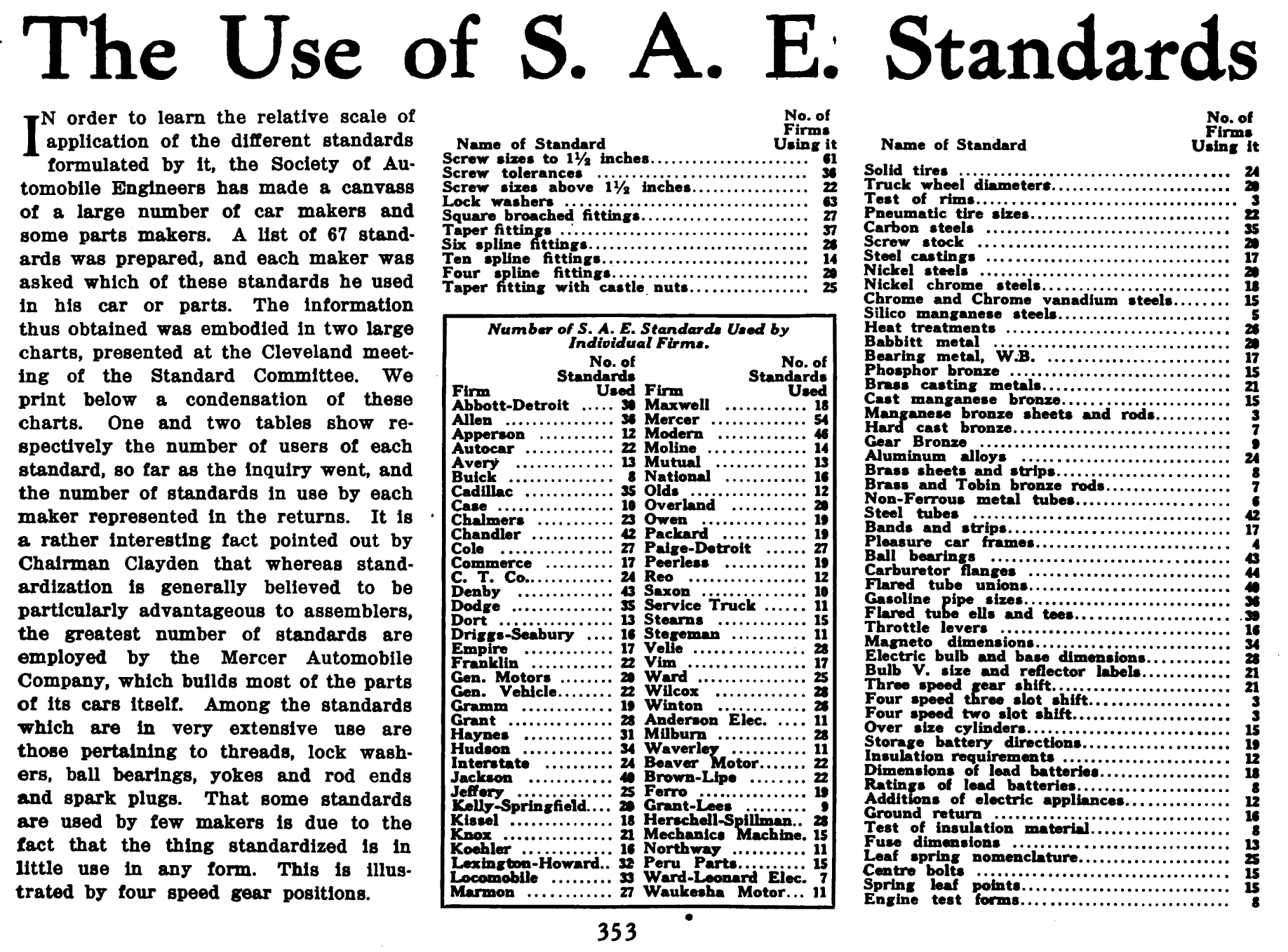

SAE International

SAE International, formerly named the Society of Automotive Engineers, is a United States-based, globally active professional association and standards developing organization for engineering professionals in various industries. SAE International's world headquarters is in Warrendale, Pennsylvania, 20 miles north of Pittsburgh, Pennsylvania. Principal emphasis is placed on global transport industries such as aerospace, automotive, and commercial vehicles. The organization adopted the name SAE International to reflect the broader emphasis on mobility. SAE International has over 138,000 global members. Membership is granted to individuals, rather than companies. Aside from its standardization efforts, SAE International also devotes resources to projects and programs in STEM education, professional certification, and collegiate design competitions. For historical legacy reasons, the label "SAE" is commonly used on tools and hardware in North America to indicate United State ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automotive Industry Action Group

The Automotive Industry Action Group'' (AIAG) is a not-for-profit association founded in 1982 and based in Southfield, Michigan. It was originally created to develop recommendations and a framework for the improvement of quality in the North American automotive industry. The association's areas of interest have expanded to include product quality standards, bar code and RFID standards, materials management, EDI, returnable containers and packaging systems, and regulatory and customs issues.AIAG Company Profile Bloomberg Business Week. Retrieved 30 September 2013. The organization was founded by representatives of the three largest North American automotive manufacturers: |

Reliability Engineering

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time. The reliability function is theoretically defined as the probability of success at time t, which is denoted R(t). This probability is estimated from detailed (physics of failure) analysis, previous data sets or through reliability testing and reliability modelling. Availability, testability, maintainability and maintenance are often defined as a part of "reliability engineering" in reliability programs. Reliability often plays the key role in the cost-effectiveness of systems. Reliability engineering deals with the prediction, prevention and mana ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design Review Based On Test Results

A design is a plan or specification for the construction of an object or system or for the implementation of an activity or process or the result of that plan or specification in the form of a prototype, product, or process. The verb ''to design'' expresses the process of developing a design. In some cases, the direct construction of an object without an explicit prior plan (such as in craftwork, some engineering, coding, and graphic design) may also be considered to be a design activity. The design usually has to satisfy certain goals and constraints; may take into account aesthetic, functional, economic, or socio-political considerations; and is expected to interact with a certain environment. Typical examples of designs include architectural and engineering drawings, circuit diagrams, sewing patterns and less tangible artefacts such as business process models. Designing People who produce designs are called ''designers''. The term 'designer' generally refers to someone who ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Mode And Effects Analysis

Failure mode and effects analysis (FMEA; often written with "failure modes" in plural) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effects. For each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet. There are numerous variations of such worksheets. An FMEA can be a qualitative analysis, but may be put on a quantitative basis when mathematical failure rate models are combined with a statistical failure mode ratio database. It was one of the first highly structured, systematic techniques for failure analysis. It was developed by reliability engineers in the late 1950s to study problems that might arise from malfunctions of military systems. An FMEA is often the first step of a system reliability study. A few different types of FMEA analyses exist, such as: * Functional * Design * Process Sometimes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DFMEA

Failure mode and effects analysis (FMEA; often written with "failure modes" in plural) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effects. For each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet. There are numerous variations of such worksheets. An FMEA can be a qualitative analysis, but may be put on a quantitative basis when mathematical failure rate models are combined with a statistical failure mode ratio database. It was one of the first highly structured, systematic techniques for failure analysis. It was developed by reliability engineers in the late 1950s to study problems that might arise from malfunctions of military systems. An FMEA is often the first step of a system reliability study. A few different types of FMEA analyses exist, such as: * Functional * Design * Process Sometime ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design Review

A design review is a milestone within a product development process whereby a design is evaluated against its requirements in order to verify the outcomes of previous activities and identify issues before committing to—and, if need be, to re-prioritise—further work. The ultimate design review, if successful, therefore triggers the product launch or product release. The conduct of design reviews is compulsory as part of design controls, when developing products in certain regulated contexts such as medical devices. By definition, a review must include persons who are external to the design team. Contents of a design review In order to evaluate a design against its requirements, a number of means may be considered, such as: *Physical tests. *Engineering simulations. *Examinations (Walk-through). Timing of design reviews Most formalised systems engineering processes recognise that the cost of correcting a fault increases as it progresses through the development process. Add ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toyota

is a Japanese multinational automotive manufacturer headquartered in Toyota City, Aichi, Japan. It was founded by Kiichiro Toyoda and incorporated on . Toyota is one of the largest automobile manufacturers in the world, producing about 10 million vehicles per year. The company was originally founded as a spinoff of Toyota Industries, a machine maker started by Sakichi Toyoda, Kiichiro's father. Both companies are now part of the Toyota Group, one of the largest conglomerates in the world. While still a department of Toyota Industries, the company developed its first product, the Type A engine in 1934 and its first passenger car in 1936, the Toyota AA. After World War II, Toyota benefited from Japan's alliance with the United States to learn from American automakers and other companies, which would give rise to The Toyota Way (a management philosophy) and the Toyota Production System (a lean manufacturing practice) that would transform the small company into a leader i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |