|

CNC Machine Tool

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CNC Machine

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is " ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Open-loop Control

In control theory, an open-loop controller, also called a non-feedback controller, is a control system in which the control action is independent of the "process output", which is the process variable that is being controlled."Feedback and control systems" - JJ Di Steffano, AR Stubberud, IJ Williams. Schaums outline series, McGraw-Hill 1967 It does not use feedback to determine if its output has achieved the desired goal of the input command or process setpoint. There are many open-loop controls, such as on/off switching of valves, machinery, lights, motors or heaters, where the control result is known to be approximately sufficient under normal conditions without the need for feedback. The advantage of using open-loop control in these cases is the reduction in component count and complexity. However, an open-loop system cannot correct any errors that it makes or correct for outside disturbances, and cannot engage in machine learning, unlike a closed-loop control system. Open- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasma Cutter

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well. Plasma cutting is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale industrial CNC applications down to small hobbyist shops. The basic plasma cutting process involves creating an electrical channel of superheated, electrically ionized gas i.e. plasma from the plasma cutter itself, through the workpiece to be cut, thus forming a completed electric circuit back to the plasma cutter through a grounding clamp. This is accomplished by a compressed gas (oxygen, air, inert and others depending on material bei ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting Tool (machining)

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The majority of these tools are designed exclusively for metals. There are several different types of single edge cutting tools that are made from a variety of hardened metal alloys that are ground to a specific shape in order to perform a specific part of the turning process resulting in a finished machined part. Single edge cutting tools are used mainly in the turning operations performed by a lathe in which they vary in size as well as alloy composition depending on the size and the type of material being turned. These cutting tools are held stationary by what is known as a tool post which is what manipulates the tools to cut the material into the desired shape. Single edge cutting tools are also the means of cutting material performed by metal s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Servomechanism

In control engineering a servomechanism, usually shortened to servo, is an automatic device that uses error-sensing negative feedback to correct the action of a mechanism. On displacement-controlled applications, it usually includes a built-in encoder or other position feedback mechanism to ensure the output is achieving the desired effect. The term correctly applies only to systems where the feedback or error-correction signals help control mechanical position, speed, attitude or any other measurable variables. For example, an automotive power window control is not a servomechanism, as there is no automatic feedback that controls position—the operator does this by observation. By contrast a car's cruise control uses closed-loop feedback, which classifies it as a servomechanism. Applications Position control A common type of servo provides ''position control''. Commonly, servos are electric, hydraulic, or pneumatic. They operate on the principle of negative feedback ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Punched Tape

Five- and eight-hole punched paper tape Paper tape reader on the Harwell computer with a small piece of five-hole tape connected in a circle – creating a physical program loop Punched tape or perforated paper tape is a form of data storage that consists of a long strip of paper in which holes are punched. It developed from and was subsequently used alongside punched cards, differing in that the tape is continuous. Punched cards, and chains of punched cards, were used for control of looms in the 18th century. Use for telegraphy systems started in 1842. Punched tape was used throughout the 19th and for much of the 20th centuries for programmable looms, teleprinter communication, for input to computers of the 1950s and 1960s, and later as a storage medium for minicomputers and CNC machine tools. During the Second World War, high-speed punched tape systems using optical readout methods were used in code breaking systems. Punched tape was used to transmit data for manufacture ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

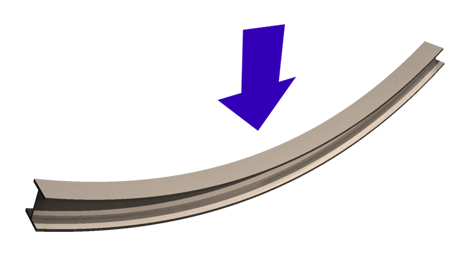

Bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a beam. For example, a closet rod sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A large diameter, but thin-walled, short tube supported at its ends an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasma Cutting

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well. Plasma cutting is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale industrial CNC applications down to small hobbyist shops. The basic plasma cutting process involves creating an electrical channel of superheated, electrically ionized gas i.e. plasma from the plasma cutter itself, through the workpiece to be cut, thus forming a completed electric circuit back to the plasma cutter through a grounding clamp. This is accomplished by a compressed gas (oxygen, air, inert and others depending on material bein ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Welding

Ultrasonic welding is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to work pieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When used to join metals, the temperature stays well below the melting point of the involved materials, preventing any unwanted properties which may arise from high temperature exposure of the metal. History Practical application of ultrasonic welding for rigid plastics was completed in the 1960s. At this point only hard plastics could be welded. The patent for the ultrasonic method for welding rigid thermoplastic parts was awarded to Robert Soloff and Seymour Linsley in 1965. Soloff, the founder of Sonics & Materials Inc., was a lab manager at Branson Inst ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Friction Stir Welding

Friction stir welding (FSW) is a solid-state joining process that uses a non-consumable tool to join two facing workpieces without melting the workpiece material. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the FSW tool. While the tool is traversed along the joint line, it mechanically intermixes the two pieces of metal, and forges the hot and softened metal by the mechanical pressure, which is applied by the tool, much like joining clay, or dough. It is primarily used on wrought or extruded aluminium and particularly for structures which need very high weld strength. FSW is capable of joining aluminium alloys, copper alloys, titanium alloys, mild steel, stainless steel and magnesium alloys. More recently, it was successfully used in welding of polymers. In addition, joining of dissimilar metals, such as aluminium to magnesium alloys, has been recently achieved by FSW. Application of FSW can be found in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron beam, friction, and ultrasound. While often a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |