|

Corrosion Fatigue

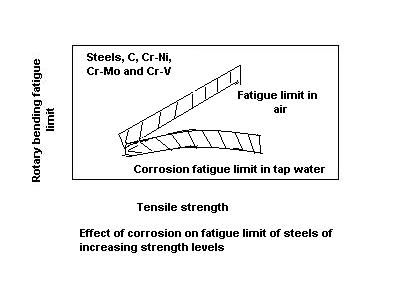

Corrosion fatigue is fatigue in a corrosive environment. It is the mechanical degradation of a material under the joint action of corrosion and cyclic loading. Nearly all engineering structures experience some form of alternating stress, and are exposed to harmful environments during their service life. The environment plays a significant role in the fatigue of high-strength structural materials like steel, aluminum alloys and titanium alloys. Materials with high specific strength are being developed to meet the requirements of advancing technology. However, their usefulness depends to a large extent on the degree to which they resist corrosion fatigue. The effects of corrosive environments on the fatigue behavior of metals were studied as early as 1930. The phenomenon should not be confused with stress corrosion cracking, where corrosion (such as pitting) leads to the development of brittle cracks, growth and failure. The only requirement for corrosion fatigue is that the samp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal crystallising because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paris' Law

Paris' law (also known as the Paris–Erdogan equation) is a crack growth equation that gives the rate of growth of a fatigue (material), fatigue crack. The stress intensity factor K characterises the load around a crack tip and the rate of crack growth is experimentally shown to be a function of the range of stress intensity \Delta K seen in a loading cycle. The Paris equation is :\begin &= C\left(\Delta K\right)^, \end where a is the crack length and a/N is the fatigue crack growth for a load cycle N. The material coefficients C and m are obtained experimentally and also depend on environment, frequency, temperature and stress ratio. The stress intensity factor range has been found to correlate the rate of crack growth from a variety of different conditions and is the difference between the maximum and minimum stress intensity factors in a load cycle and is defined as : \Delta K= K_-K_. Being a power law relationship between the crack growth rate during cyclic loadin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Structural Engineering

Structural engineering is a sub-discipline of civil engineering in which structural engineers are trained to design the 'bones and joints' that create the form and shape of human-made Structure#Load-bearing, structures. Structural engineers also must understand and calculate the structural stability, stability, strength, structural rigidity, rigidity and earthquake-susceptibility of built structures for buildings and nonbuilding structures. The structural designs are integrated with those of other designers such as architects and Building services engineering, building services engineer and often supervise the construction of projects by contractors on site. They can also be involved in the design of machinery, medical equipment, and vehicles where structural integrity affects functioning and safety. See glossary of structural engineering. Structural engineering theory is based upon applied physics, physical laws and empirical knowledge of the structural performance of different ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress (mechanics)

In continuum mechanics, stress is a physical quantity that describes forces present during deformation. For example, an object being pulled apart, such as a stretched elastic band, is subject to ''tensile'' stress and may undergo elongation. An object being pushed together, such as a crumpled sponge, is subject to ''compressive'' stress and may undergo shortening. The greater the force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Stress has dimension of force per area, with SI units of newtons per square meter (N/m2) or pascal (Pa). Stress expresses the internal forces that neighbouring particles of a continuous material exert on each other, while ''strain'' is the measure of the relative deformation of the material. For example, when a solid vertical bar is supporting an overhead weight, each particle in the bar pushes on the particles immediately below it. When a liquid is in a closed container under pressure, each ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress Corrosion Cracking

Stress corrosion cracking (SCC) is the growth of crack formation in a corrosive environment. It can lead to unexpected and sudden failure of normally ductile metal alloys subjected to a tensile stress, especially at elevated temperature. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when exposed to a small number of chemical environments. The chemical environment that causes SCC for a given alloy is often one which is only mildly corrosive to the metal. Hence, metal parts with severe SCC can appear bright and shiny, while being filled with microscopic cracks. This factor makes it common for SCC to go undetected prior to failure. SCC often progresses rapidly, and is more common among alloys than pure metals. The specific environment is of crucial importance, and only very small concentrations of certain highly active chemicals are needed to produce catastrophic cracking, often leading to devastating and unexpected failure. The stresse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal crystallising because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cyclic Corrosion Testing

Cyclic Corrosion Testing (CCT) has evolved in recent years, largely within the automotive industry, as a way of accelerating real-world corrosion failures, under laboratory controlled conditions. As the name implies, the test comprises different climates which are cycled automatically so the samples under test undergo the same sort of changing environment that would be encountered in the natural world. The intention being to bring about the type of failure that might occur naturally, but more quickly i.e. accelerated. By doing this manufacturers and suppliers can predict, more accurately, the service life expectancy of their products. Until the development of Cyclic Corrosion Testing, the traditional Salt spray test was virtually all that manufacturers could use for this purpose. However, this test was never intended for this purpose. Because the test conditions specified for salt spray testing are not typical of a naturally occurring environment, this type of test cannot be used ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion. In the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen, or hydroxide. Rusting, the formation of red-orange iron oxides, is a well-known example of electrochemical corrosion. This type of corrosion typically produces oxides or salts of the original metal and results in a distinctive coloration. Corrosion can also occur in materials other than metals, such as ceramics or polymers, although in this context, the term "degradation" is more common. Corrosion degrades the useful properties of materials and structures including mechanical strength, appearance, and permeability to liquids and ga ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combined True & Stress Corrosion Fatigue

{{Disambiguation ...

Combined may refer to: * Alpine combined (skiing), the combination of slalom and downhill skiing as a single event ** Super combined (skiing) * Nordic combined (skiing), the combination of cross country skiing and ski jumping as a single event * The Combined (Group), a criminal organization * CombinedX, a Swedish group of IT companies See also * * Combo (other) * Combine (other) * Combination (other) A combination is a mathematical collection of things in a context where their specific order is irrelevant. Combination, combinations, or combo may also refer to: * Combination (chess), a relatively long sequence of chess moves, involving tempora ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress Corrosion Fatigue

Stress may refer to: Science and medicine * Stress (biology), an organism's response to a stressor such as an environmental condition * Stress (linguistics), relative emphasis or prominence given to a syllable in a word, or to a word in a phrase or sentence * Stress (mechanics), the internal forces that neighboring particles of a continuous material exert on each other * Oxidative stress, an imbalance of free radicals * Psychological stress, a feeling of strain and pressure ** Occupational stress, stress related to one's job * Surgical stress, systemic response to surgical injury Arts, entertainment, and media Music Groups and musicians * Stress (Brazilian band), a Brazilian heavy metal band * Stress (British band), a British rock band * Stress (pop rock band), an early 1980s melodic rock band from San Diego * Stress (musician) (born 1977), hip hop singer from Switzerland * Stress (record producer) (born 1979), artistic name of Can Canatan, Swedish musician and record ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Particle Size (grain Size)

Grain size (or particle size) is the diameter of individual grains of sediment, or the lithified particles in clastic rocks. The term may also be applied to other granular materials. This is different from the crystallite size, which refers to the size of a single crystal inside a particle or grain. A single grain can be composed of several crystals. Granular material can range from very small colloidal particles, through clay, silt, sand, gravel, and cobbles, to boulders. Krumbein phi scale Size ranges define limits of classes that are given names in the Wentworth scale (or Udden–Wentworth scale named after geologists Chester K. Wentworth and Johan A. Udden) used in the United States. The Krumbein ''phi'' (φ) scale, a modification of the Wentworth scale created by W. C. Krumbein in 1934, is a logarithmic scale computed by the equation :\varphi=-\log_2, where :\varphi is the Krumbein phi scale, :D is the diameter of the particle or grain in millimeters (Krumbein a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pitting Corrosion

Pitting corrosion, or pitting, is a form of extremely localized corrosion that leads to the random creation of small holes in metal. The driving power for pitting corrosion is the depassivation of a small area, which becomes anodic (oxidation reaction) while an unknown but potentially vast area becomes cathodic (reduction reaction), leading to very localized galvanic corrosion. The corrosion penetrates the mass of the metal, with a limited diffusion of ions. Another term arises, pitting factor, which is defined as the ratio of the depth of the deepest pit (resulting due to corrosion) to the average penetration, which can be calculated based on the weight loss. Development and kinetics of pitting According to Frankel (1998) who performed a review on pitting corrosion, it develops in three successive steps: (or nucleation) by breakdown of the passive film protecting the metal surface from oxidation, (2) growth of metastable pits (growing up to the micron scale and then repassivat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |