|

Concrete

Concrete is a composite material composed of aggregate bound together with a fluid cement that cures to a solid over time. It is the second-most-used substance (after water), the most–widely used building material, and the most-manufactured material in the world. When aggregate is mixed with dry Portland cement and water, the mixture forms a fluid slurry that can be poured and molded into shape. The cement reacts with the water through a process called hydration, which hardens it after several hours to form a solid matrix that binds the materials together into a durable stone-like material with various uses. This time allows concrete to not only be cast in forms, but also to have a variety of tooled processes performed. The hydration process is exothermic, which means that ambient temperature plays a significant role in how long it takes concrete to set. Often, additives (such as pozzolans or superplasticizers) are included in the mixture to improve the physical prop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

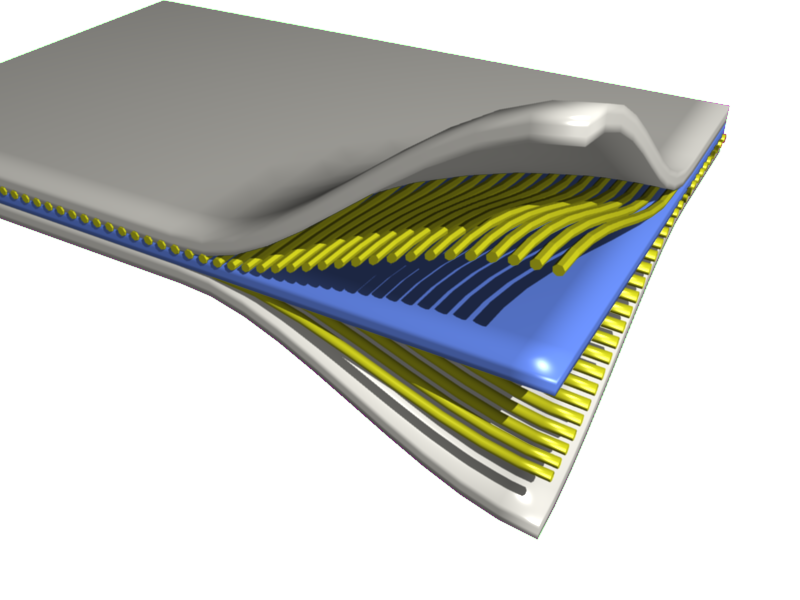

Reinforced Concrete

Reinforced concrete, also called ferroconcrete or ferro-concrete, is a composite material in which concrete's relatively low tensile strength and ductility are compensated for by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel reinforcing bars (known as rebar) and is usually embedded passively in the concrete before the concrete sets. However, post-tensioning is also employed as a technique to reinforce the concrete. In terms of volume used annually, it is one of the most common engineering materials. In corrosion engineering terms, when designed correctly, the alkalinity of the concrete protects the steel rebar from corrosion. Description Reinforcing schemes are generally designed to resist tensile stresses in particular regions of the concrete that might cause unacceptable cracking and/or structural failure. Modern reinforced concrete can contain varied reinforcing materials made o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rebar

Rebar (short for reinforcement bar or reinforcing bar), known when massed as reinforcing steel or steel reinforcement, is a tension device added to concrete to form ''reinforced concrete'' and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar usually consists of steel bars which significantly increase the tensile strength of the structure. Rebar surfaces feature a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage. The most common type of rebar is carbon steel, typically consisting of hot-rolled round bars with deformation patterns embossed into its surface. Steel and concrete have similar coefficients of thermal expansion, so a concrete structural member reinforced with steel will experience minimal differential stress as the temperature changes. Other readily available types of rebar are manufacture ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Types Of Concrete

Concrete is produced in a variety of compositions, finishes and performance characteristics to meet a wide range of needs. Mix design Modern concrete mix designs can be complex. The choice of a concrete mix depends on the need of the project both in terms of strength and appearance and in relation to local legislation and building codes. The design begins by determining the requirements of the concrete. These requirements take into consideration the weather conditions that the concrete will be exposed to in service, and the required design strength. The compressive strength of a concrete is determined by taking standard molded, standard-cured cylinder samples. Many factors need to be taken into account, from the cost of the various additives and aggregates, to the trade offs between the "slump" for easy mixing and placement and ultimate performance. A mix is then designed using cement (Portland or other cementitious material), coarse and fine aggregates, water and chemical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource. Cements used in construction are usually inorganic, often lime- or calcium silicate-based, and are either hydraulic or less commonly non-hydraulic, depending on the ability of the cement to set in the presence of water (see hydraulic and non-hydraulic lime plaster). Hydraulic cements (e.g., Portland cement) set and become adhesive through a chemical reaction between the dry ingredients and water. The chemical reaction results in mineral hydrates that are not very water-soluble. This allows setting in wet conditions or under ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource. Cements used in construction are usually inorganic, often lime- or calcium silicate-based, and are either hydraulic or less commonly non-hydraulic, depending on the ability of the cement to set in the presence of water (see hydraulic and non-hydraulic lime plaster). Hydraulic cements (e.g., Portland cement) set and become adhesive through a chemical reaction between the dry ingredients and water. The chemical reaction results in mineral hydrates that are not very water-soluble. This allows setting in wet conditions or u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Portland Cement

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar (masonry), mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and is usually made from limestone. It is a fine powder (substance), powder, produced by heating limestone and clay minerals in a kiln to form Clinker (cement), clinker, and then #Cement grinding, grinding the clinker with the addition of several percent (often around 5%) gypsum. Several types of portland cement are available. The most common, historically called ordinary portland cement (OPC), is grey, but white portland cement is also available. The cement was so named by Joseph Aspdin, who obtained a patent for it in 1824, because, once hardened, it resembled the fine, pale limestone known as Portland stone, quarried from the windswept cliffs of the Isle of Portland in Dorset. Portland stone was p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Concrete

Polymer concrete is a type of concrete that uses a polymer to replace lime-type cements as a binder. One specific type is epoxy granite, where the polymer used is exclusively epoxy. In some cases the polymer is used in addition to portland cement to form Polymer Cement Concrete (PCC) or Polymer Modified Concrete (PMC).Composite Structures for Civil and Architectural Engineering By D-H Kim Polymers in concrete have been overseen by Committee 548 of the American Concrete Institute since 1971. Composition In polymer concrete,[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Road Surface

A road surface (British English) or pavement (North American English) is the durable surface material laid down on an area intended to sustain vehicular or foot traffic, such as a road or walkway. In the past, gravel road surfaces, macadam, hoggin, cobblestone and granite setts were extensively used, but these have mostly been replaced by asphalt or concrete laid on a compacted base course. Asphalt mixtures have been used in pavement construction since the beginning of the 20th century and are of two types: metalled (hard-surfaced) and unmetalled roads. Metalled roadways are made to sustain vehicular load and so are usually made on frequently used roads. Unmetalled roads, also known as gravel roads or dirt roads, are rough and can sustain less weight. Road surfaces are frequently marked to guide traffic. Today, permeable paving methods are beginning to be used for low-impact roadways and walkways to prevent flooding. Pavements are crucial to countries such as United St ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Superplasticizer

Superplasticizers (SPs), also known as high range water reducers, are Concrete additive, additives used for making high strength concrete or to place Self-consolidating concrete, self-compacting concrete. Plasticizers are chemical compounds enabling the production of concrete with approximately 15% less water content. Superplasticizers allow reduction in water content by 30% or more. These additives are employed at the level of a few weight percent. Plasticizers and superplasticizers also retard the setting and hardening of concrete. According to their Dispersant, dispersing functionality and action mode, one distinguishes two classes of superplasticizers: # Ionic bonding, Ionic interactions (electrostatic repulsion): lignosulfonates (first generation of ancient water reducers), Aromatic sulfonation, sulfonated synthetic polymers (naphthalene, or melamine, formaldehyde Condensation polymer, condensates) (second generation), and; # Steric effects: Polycarboxylates-ether (PCE) synt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Composite materials with more than one distinct layer are called ''composite laminates''. Typical engineered composite materials are made up of a binding agent forming the ''matrix'' and a Filler (materials), filler material (particulates or fibres) giving ''substance'', e.g.: * Concrete, reinforced concrete and masonry with cement, lime or Mortar (masonry), mortar (which is itself a composite material) as a binder * Composite wood such as glulam and plywood with wood glue as a binder * Reinforced plastics, such as fiberglass and fibre-rein ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

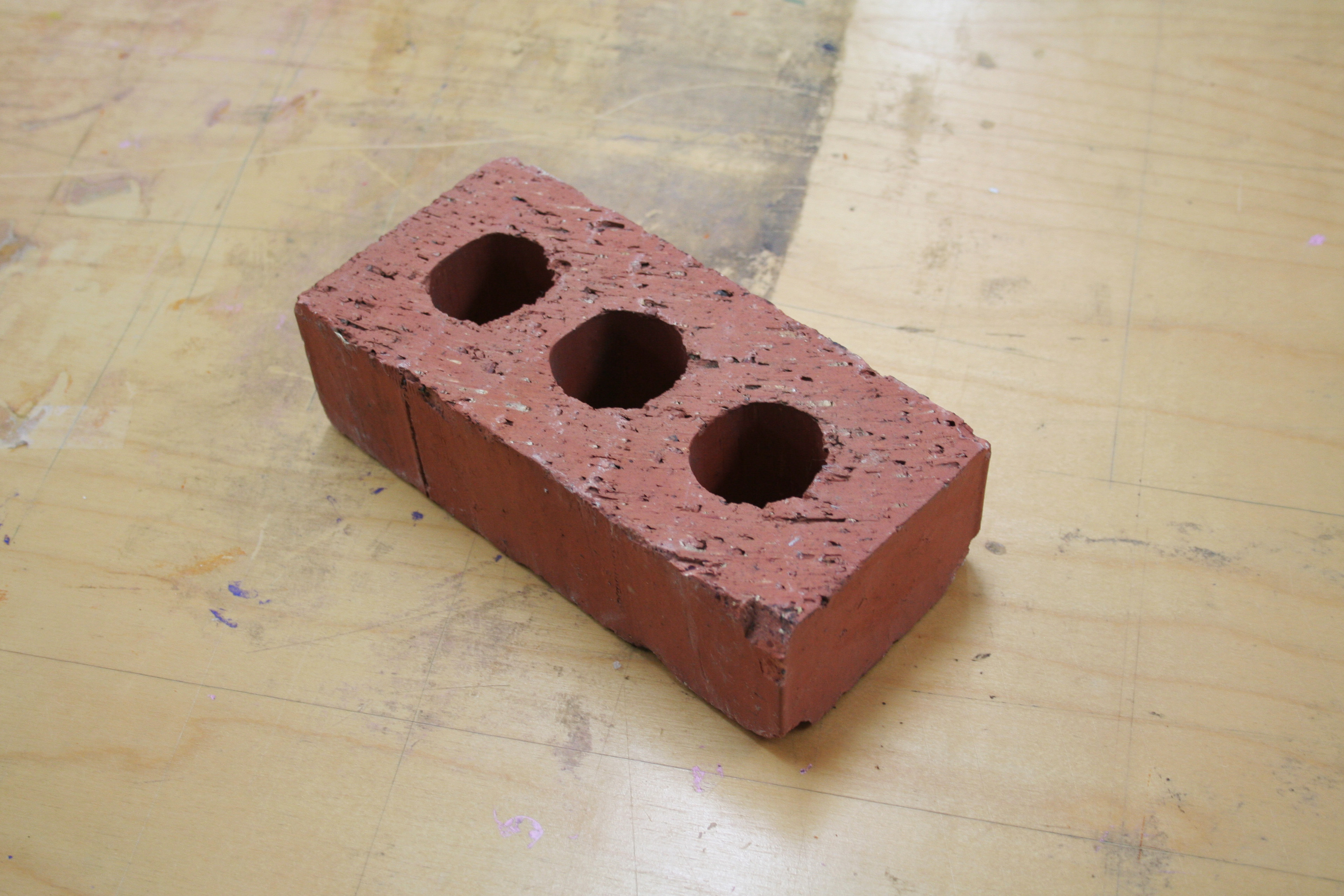

Brick

A brick is a type of construction material used to build walls, pavements and other elements in masonry construction. Properly, the term ''brick'' denotes a unit primarily composed of clay. But is now also used informally to denote building units made of other materials or other chemically cured construction blocks. Bricks can be joined using Mortar (masonry), mortar, adhesives or by interlocking. Bricks are usually produced at brickworks in numerous classes, types, materials, and sizes which vary with region, and are produced in bulk quantities. Concrete masonry unit, ''Block'' is a similar term referring to a rectangular building unit composed of clay or concrete, but is usually larger than a brick. Lightweight bricks (also called lightweight blocks) are made from expanded clay aggregate. Fired bricks are one of the longest-lasting and strongest building materials, sometimes referred to as artificial stone, and have been used since . Air-dried bricks, also known as mudbricks ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

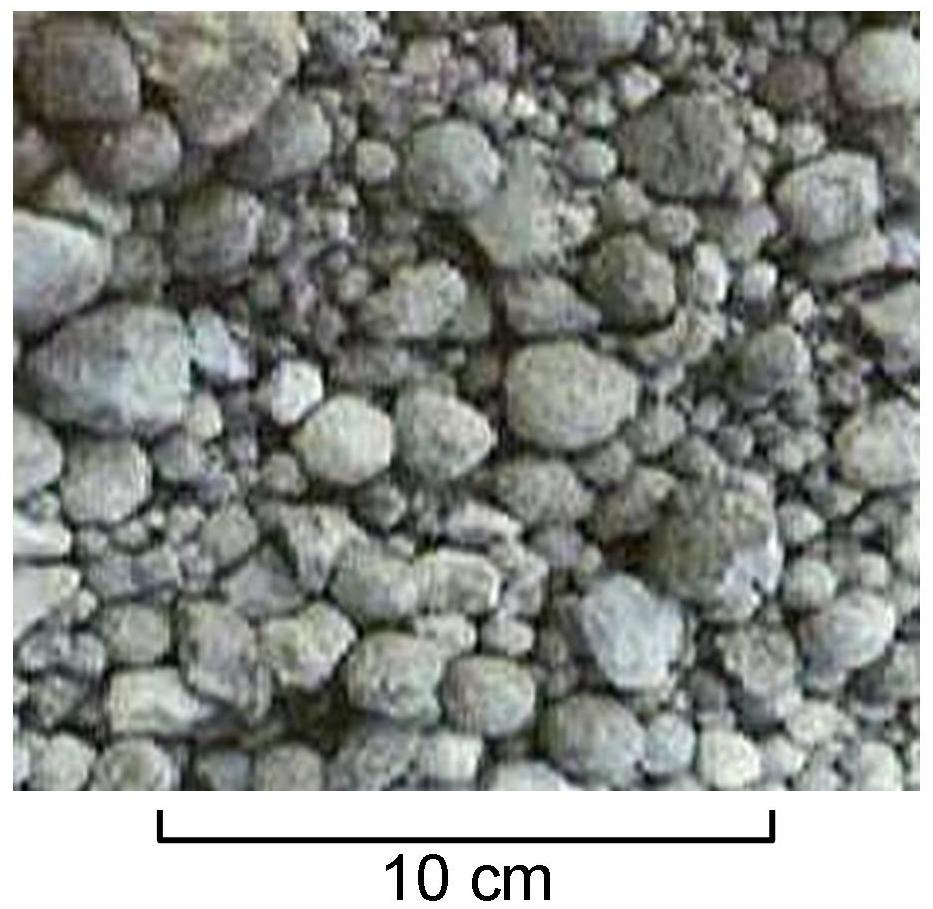

Construction Aggregate

Construction aggregate, or simply aggregate, is a broad category of coarse- to medium-grained particulate material used in construction. Traditionally, it includes natural materials such as sand, gravel, crushed stone. As with other types of aggregates, it is a component of composite materials, particularly concrete and asphalt. Aggregates are the most mined materials in the world,Introduction (1): What are Aggregates? « Herefordshire & Worcestershire Earth Heritage TrustIntroduction (1): What are Aggregates? « Herefordshire & Worcestershire Earth Heritage Trust, accessdate: March 23, 2017Define Aggregate at Dictionary.comaggregate accessdate: March 23, 2017 being a significant part of 6 billion tons of concrete produced per year. Aggregate serves as reinforcement to add strength to the resulting material. Due to the relatively high hydraulic conductivity as compared to most soil types, aggregates are widely used in drainage applications such as foundation and French drain ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |