|

Choke Valve

In internal combustion engines with carburetors, a choke valve or choke modifies the air pressure in the intake manifold, thereby altering the air–fuel ratio entering the engine. Choke valves are generally used in naturally aspirated engines to supply a richer fuel mixture when starting the engine. Most choke valves in engines are butterfly valves mounted upstream of the carburetor jet to restrict air flow there and produce a higher partial vacuum downstream, which increases the fuel draw. In heavy industrial or fluid engineering contexts, including oil and gas production, a choke valve or choke is a particular design of valve with a solid cylinder placed inside another slotted or perforated cylinder. Carburetor A choke valve is sometimes installed in the carburetor of internal combustion engines. Its purpose is to restrict the flow of air, thereby enriching the fuel-air mixture while starting the engine. Depending on engine design and application, the valve can be activated ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons (reciprocating engine, piston engine), turbine blades (gas turbine), a Wankel engine, rotor (Wankel engine), or a propulsive nozzle, nozzle (jet engine). This force moves the component over a distance. This process transforms chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. The first commercially successful internal combustion engines were invented in the mid-19th century. The first modern internal combustion engine, the Otto engine, was designed in 1876 by the German engineer Nicolaus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Injection

Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of a fuel injector. This article focuses on fuel injection in reciprocating piston and Wankel rotary engines. All compression-ignition engines (e.g. diesel engines), and many spark-ignition engines (i.e. petrol (gasoline) engines, such as Otto or Wankel), use fuel injection of one kind or another. Mass-produced diesel engines for passenger cars (such as the Mercedes-Benz OM 138) became available in the late 1930s and early 1940s, being the first fuel-injected engines for passenger car use. In passenger car petrol engines, fuel injection was introduced in the early 1950s and gradually gained prevalence until it had largely replaced carburetors by the early 1990s. The primary difference between carburetion and fuel injection is that fuel injection atomizes the fuel through a small nozzle under high pressure, while carburetion relies on suction crea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HowStuffWorks

HowStuffWorks is an American commercial infotainment website founded by professor and author Marshall Brain, to provide its target audience an insight into the way many things work. The site uses various media to explain complex concepts, terminology, and mechanisms—including photographs, diagrams, videos, animations, and articles. The website was acquired by Discovery Communications in 2007, but was sold to Blucora in 2014. The site has since expanded out into podcasting, focusing on factual topics. In December 2016, HowStuffWorks, LLC became a subsidiary of OpenMail, LLC, later renamed System1. In 2018, the podcast division of the company, which had been spun-off by System1 under the name Stuff Media, was acquired by iHeartMedia for $55 million. History In 1998, then North Carolina State University instructor Marshall Brain (1961–2024), started the site as a hobby. In 1999, Brain raised venture capital and formed HowStuffWorks, Inc. In March 2002, HowStuffWorks wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inconel

Inconel is a nickel-chromium-based superalloy often utilized in extreme environments where components are subjected to high temperature, pressure or Mechanical load, mechanical loads. Inconel alloys are oxidation- and corrosion-resistant. When heated, Inconel forms a thick, stable, passivation (chemistry), passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminum and steel would succumb to creep (deformation), creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.Inconel alloy 718 , Special Metals Corporation Inconel all ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

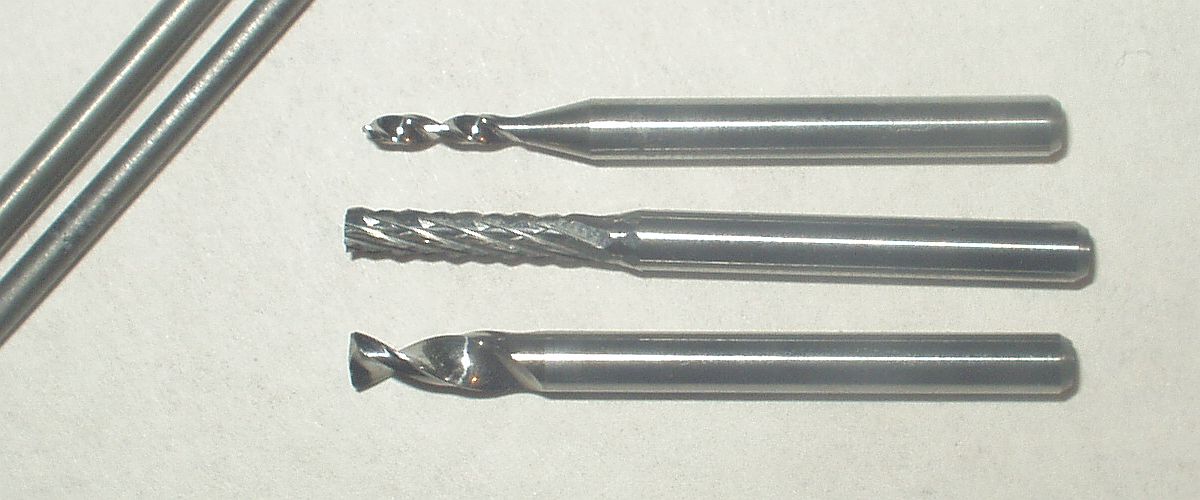

Tungsten Carbide

Tungsten carbide (chemical formula: ) is a carbide containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, engineering facilities, molding blocks, cutting tools, chisels, abrasives, armor-piercing bullets and jewelry. Tungsten carbide is approximately three times as stiff as steel, with a Young's modulus of approximately 530–700 GPa, and is twice as dense as steel. It is comparable with corundum (α- ) in hardness, approaching that of a diamond, and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond. Tungsten carbide tools can be operated at cutting speeds much higher than high-speed steel (a special steel blend for cutting tools). Tungsten carbide powder was first synthesized by H. Moissan in 1893, and the industrial production of the cemented form starte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flow Coefficient

The flow coefficient of a device is a relative measure of its efficiency at allowing fluid flow. It describes the relationship between the pressure drop across an orifice valve or other assembly and the corresponding flow rate. A greater restriction in flow will create a larger pressure drop across a device and thus a smaller flow coefficient, conversely device with little restriction in flow will have a small pressure drop and a larger flow coefficient. For example, the flow coefficient of a 1" ball valve may be 80 while a similarly sized globe valve in the same application may be 10. Mathematically the flow coefficient (or flow-capacity rating of valve) can be expressed as C_\text = Q \sqrt, where, : is the rate of flow (expressed in US gallons per minute), : SG is the specific gravity of the fluid (for water = 1), : is the pressure drop across the valve (expressed in psi). In more practical terms, the ''flow coefficient'' is the volume (in US gallons) of water at that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

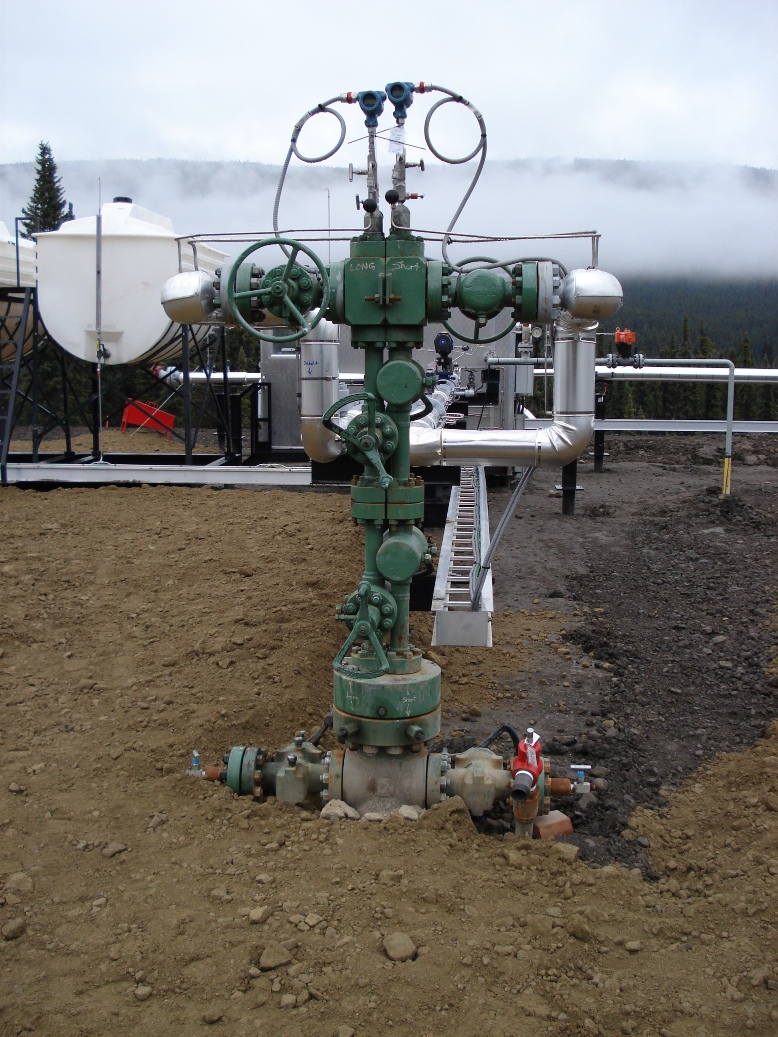

Wellhead

A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The primary purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings that run from the bottom of the hole sections to the surface pressure control equipment. While drilling the oil well, surface pressure control is provided by a blowout preventer (BOP). If the pressure is not contained during drilling operations by the column of drilling fluid, casings, wellhead, and BOP, a well blowout could occur. When the well has been drilled, it is completed to provide an interface with the reservoir rock and a tubular conduit for the well fluids. The surface pressure control is provided by a Christmas tree, which is installed on top of the wellhead, with isolation valves and choke equipment to control the flow of well fluids during production. Wellheads are typically welded ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Christmas Tree (oil Well)

In petroleum and natural gas extraction, a Christmas tree, or tree, is an assembly of valves, casing spools, and fittings used to regulate the flow of pipes in an oil well, gas well, water injection well, water disposal well, gas injection well, condensate well, and other types of well. Overview The first primitive Christmas tree was used by the Hamill Brothers to bring Spindletop under control. It consisted of a T-valve, with a and valve on the vertical pipe, and a 6-inch valve on the horizontal pipe. The vertical valve was closed first, and then the valve to the horizontal pipe. Christmas trees are used on both surface and subsea wells. It is common to identify the type of tree as either "subsea tree" or "surface tree". Each of these classifications has a number of variations. Examples of subsea include conventional, dual bore, mono bore, TFL (through flow line), horizontal, mudline, mudline horizontal, side valve, and TBT (through-bore tree) trees. The deepest installe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Volumetric Flow Rate

In physics and engineering, in particular fluid dynamics, the volumetric flow rate (also known as volume flow rate, or volume velocity) is the volume of fluid which passes per unit time; usually it is represented by the symbol (sometimes \dot V). Its SI unit is cubic metres per second (m3/s). It contrasts with '' mass flow rate'', which is the other main type of fluid flow rate. In most contexts a mention of "rate of fluid flow" is likely to refer to the volumetric rate. In hydrometry, the volumetric flow rate is known as '' discharge''. The volumetric flow rate across a unit area is called '' volumetric flux'', as defined by Darcy's law and represented by the symbol . Conversely, the integration of a volumetric flux over a given area gives the volumetric flow rate. Units The SI unit is cubic metres per second (m3/s). Another unit used is standard cubic centimetres per minute (SCCM). In US customary units and imperial units, volumetric flow rate is often expressed as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Drop

Pressure drop (often abbreviated as "dP" or "ΔP") is defined as the difference in total pressure between two points of a fluid carrying network. A pressure drop occurs when frictional forces, caused by the resistance to flow, act on a fluid as it flows through a conduit (such as a channel, pipe, or tube). This friction converts some of the fluid's hydraulic energy to thermal energy (i.e., internal energy). Since the thermal energy cannot be converted back to hydraulic energy, the fluid experiences a drop in pressure, as is required by conservation of energy. The main determinants of resistance to fluid flow are fluid velocity through the pipe and fluid viscosity. Pressure drop increases proportionally to the frictional shear forces within the piping network. A piping network containing a high relative roughness rating as well as many pipe fittings and joints, tube convergence, divergence, turns, surface roughness, and other physical properties will affect the pressure drop. Hig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flow Limiter

A flow limiter or flow restrictor is a device to restrict the flow of a fluid, in general a gas or a liquid. Some designs use single stage or multi-stage orifice plates to handle high and low flow rates. Flow limiters are often used in manufacturing plants as well as households. Safety is usually the main purpose of using a flow limiter. An example is manufacturing facilities and laboratories using flow limiters to prevent injury or death from noxious gases that are in use. The flow limiter prevents gases from causing injury or death by reducing its cross-sectional area where gas flows. Uses * Reduce flow of fluid (velocity) through a system, e.g. to reduce water usage in a shower * Reduce the amount of gas passing through a system * Reduce pressure in a system * Applications in medical instrumentation * As a safety valve to provide limited flow after closing in the event of a broken hose. (See '' Hydraulic fuse''). Specifications *Orifice diameter *Flow tolerance *Media temperatu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extraction Of Petroleum

Petroleum is a fossil fuel that can be drawn from beneath the Earth's surface. Reservoirs of petroleum are formed through the mixture of plants, algae, and sediments in shallow seas under high pressure. Petroleum is mostly recovered from oil drilling. Seismic surveys and other methods are used to locate oil reservoirs. Oil rigs and oil platforms are used to drill long holes into the earth to create an oil well and extract petroleum. After extraction, oil is refined to make gasoline and other products such as tires and refrigerators. Extraction of petroleum can be dangerous and has led to oil spills. Locating the oil field Geologists and geophysicists use seismic surveys to search for geological structures that may form oil reservoirs. The "classic" method includes making an underground explosion nearby and observing the seismic response, which provides information about the geological structures underground. However, "passive" methods that extract information from naturall ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |